Using A Parallel Micro-Cultivation System As

Di: Ava

Abstract Microbioreactors are increasingly used within animal cell biotechnology to grow mammalian cells for cell line screening and to facilitate process development. Many such devices have been reported in the literature, but only a small number are available commercially. Microbioreactors range in complexity from simple plate-based systems to complex automated Tsinghua University. This protocol describes how to use the Single-cell Microliter-droplet Culture Omics System (MISS cell) to perform microbial monoclonal isolation, cultivation, and picking. The MISS cell achieves an integrated workflow based on droplet microfluidic technology, which offers excellent droplet monodispersity, high parallel cultivation, and high

The system was first characterised to gain a better understanding of the cultivation environment within each well and to identify a suitable scaling criterion to a reference benchtop-scale bioreactor system. Mixing times were found to range between 1 – 42 s, while the volumetric mass transfer coefficient (kLa) was 2.4 – 240.8 h-1. The development of automated, modular microbial cell micro-cultivation systems, particularly those employing droplet microfluidics, has gained attention for their high-throughput, parallel and Abstract The development of mini- and micro-cultivation devices allows the optimization of bioprocesses to be speeded up, as well as a better understanding of microbial physiology under process conditions. Mini-bioreactors have been specifically developed for the parallel cultivation of microorganisms under process-representative

In this study, we combine mechanistic growth models with a parallel mini-bioreactor system to create a high-throughput platform for studying the response of Escherichia coli strains to concentration gradients. An integrated platform called microbial microdroplet culture system (MMC), which can perform various accurate and reproducible operations on microliter droplets, is developed for automated, high-throughput cultivation and adaptive evolution of multiple microorganisms. Here, Jian and Guo validate the superior performance of MMC for microbial cultivation by comparing Chemostat cultivation is a powerful tool for physiological studies of microorganisms. We report the construction and application of a set of eight parallel small-scale bioreactors with a working volume of 10 mL for continuous cultivation. Hungate tubes were used as culture vessels connected to multichannel-peristaltic pumps for feeding fresh media and removal of culture

A Novel Microbial Culture Chamber Co-cultivation System to

The dimensions of the micro bioreactors were similar as the wells in a 96-well microtiter plate, to preserve compatibility with the current high-throughput cultivation systems. Abstract Decreasing the timeframe for cell culture process development has been a key goal toward accelerating biopharmaceutical development. Advanced Microscale Bioreactors (ambr™) is an automated micro-bioreactor system with miniature single-use bioreactors with a 10–15 mL working volume controlled by an automated workstation. The DASGIP Parallel Bioreactor Systems and the DASbox Mini Bioreactor System for cell culture applications allow the parallel operation of up to 16 and 24 bioreactors respectively and support the use of both conventional glass and BioBLU Single-Use Vessels.

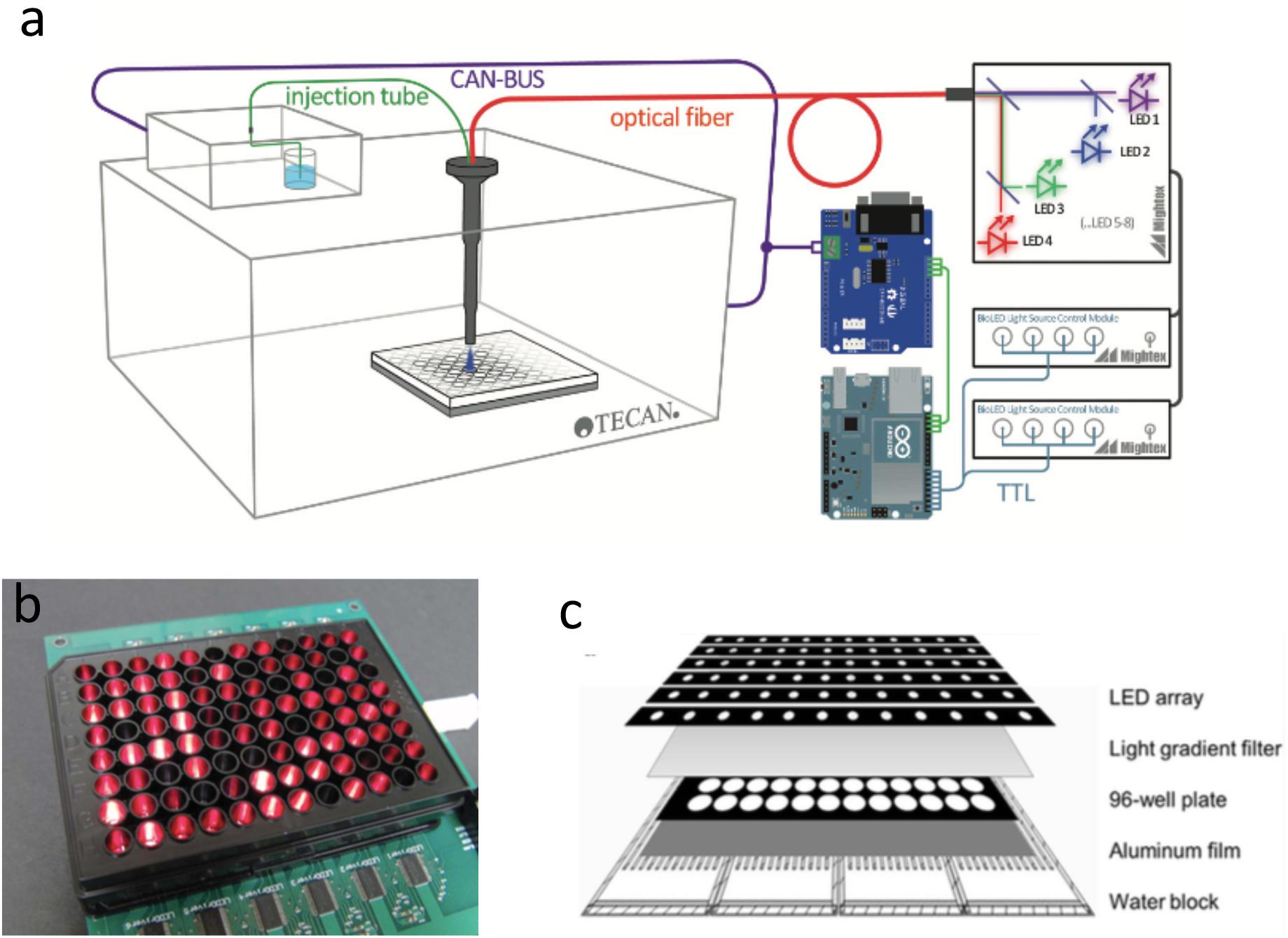

In this study, we developed a simple microfluidic device for highly parallel co-cultivation of symbiotic microbial communities and demonstrated its effectiveness in discovering synergistic

Effluent water from recirculating aquaculture systems (RAS) contains nutrients from fish excrements and leftover feed. This study investigated the nutrient remediation potential from RAS effluent water through microalgae cultivation in 25 L tubular reactors. We compared nutrient uptake and biomass productivity in continuous and perfusion cultivation modes for freshwater,

We present an automated mini bioreactor platform that enables parallel cultivations in the milliliter scale with online monitoring and control, well Abstract This protocol explains how to prepare and conduct CHO cell culture processes in the DASbox Mini Bioreactor System and the DASGIP Parallel Bioreactor Systems. We guide the user through all steps of a bioprocess, starting from the preparation of the inoculum to the preparation and operation of the vessels and bioprocess systems, the bioprocess run itself, and the

- Miniature bioreactors: current practices and future opportunities

- Recent advances in fed-batch microscale bioreactor design

- A Novel Microbial Culture Chamber Co-cultivation System to

- Microfluidic devices for cell cultivation and proliferation

Scientists at the Forschungszentrum Jülich have been using a cultivation set-up consisting of two connected stirred-tank reactors (STRs) to simulate inhomogeneous cultivation conditions as they can occur in production scale. In this application note, we describe the efects of oscillating DO and substrate concentation. A Novel Microbial Culture Chamber Co-cultivation System to Study Algal-Bacteria Interactions Using Emiliania huxleyi and Phaeobacter inhibens as Model Organisms Mariane S. Thøgersen 1† Jette Melchiorsen 1 Colin Ingham 2 Lone Gram 1*

Bioprocess development, optimization, and control in mini-bioreactor systems require information about essential process parameters, high data densities, and the ability to dynamically change process conditions. We present an integration approach combining a parallel mini-bioreactor system integrated into a liquid handling station (LHS) with a second LHS for Online 2D Fluorescence Monitoring in Microtiter Plates Allows Prediction of Cultivation Parameters and Considerable Reduction in Sampling Efforts for Parallel

This review focuses on recent developments in the field of miniaturized stirred tank bioreactors for application in high-throughput bioprocess development. Different reactor concepts and their potential for parallel bioprocess development are discussed. A detailed description of important engineering state variables, their measurement at small-scale and their implication The proposed method is tested with data from several parallel cultivations from a 24 mini-bioreactors platform containing an Escherichia coli strain operating in fed-batch mode. The results highlight both the versatility of the approach to estimate parameter distribution as well as to predict the state evolution. Microbioreactors (MBRs) have emerged as potent cultivation devices enabling automated small-scale experiments in parallel while enhancing their cost efficiency. The widespread use of MBRs has contributed to recent advances in industrial and pharmaceutical

The enormous capability of microalgae for biomass production and co-products has recently been widely researched from a range of research approaches. Microalgae biomass has been discovered as a suitable feedstock for biofuel generation in the third generation. Although they may easily be cultivated in the laboratory, commercial cultivation involves In this study, we selected the BioLector micro-bioreactor (µ-bioreactor) system as an HTP cultivation platform to screen E. coli expression clones producing representative protein candidates for

Comparable product titres were obtained for controlled DO-stat fed-batch cultivation using the micro-Matrix and 2 L stirred tank bioreactors, highlighting the scalability of the system. In this work, we aimed to make use of highly parallel micro-droplets to co-cultivate symbiotic microbial communities. We fabricated a microfluidic device that could readily encapsulate and co-cultivate subsets of a community, using aqueous droplets dispersed in a continuous oil phase.

- CHO Cell Cultivation in a DASbox® Mini Bioreactor System

- Hydroponic Systems for Cultivation of Horticultural Crops

- Algae Cultivation Systems

This article contains a list of good manhwas with System. This includes Manhua, Manga, Webtoons, and other comics where the System Initial fed-batch cultivation using concentrated feeds. a Fed-batch GS-CHO culture kinetics with a 2% (v/v) daily bolus feed followed by a 0.25% (v/v) shot of bicarbonate solution for 5 Abstract This protocol explains how to prepare and conduct E. coli fermentation processes in the DASbox Mini Bioreactor System and the DASGIP Parallel Bioreactor Systems. We would like to give an overview on the steps that have to be taken during the preparation and conduction of a bioprocess run. We also explain how these difer with the use of glass and BioBLU® Single-Use

In this study, we developed a simple microfluidic device for highly parallel co-cultivation of symbiotic microbial communities and demonstrated its effectiveness in discovering synergistic interactions among microbes.

In this study, a self-developed 8-parallel micro-bioreactor system with non-invasive optical biosensors was introduced to substitute the traditional shake flask. Algae are a diverse group of micro- and macroscopic, highly efficient photosynthetic organisms with rapid growth and flourish in a variety of environments where many land plants are uninhabitable. Algal biomass contains a wide range of In this study, we combine mechanistic growth models with a parallel mini-bioreactor system to create a high-throughput platform for

These systems ensure efficient use of nutrients and water by the plants as compared to the field-based agriculture. Urban farming techniques like hydroponics or soilless culture of crops reduce the negative effects of pollution while also improving the sustainability of urban living by supplying basic dietary requirements through

We present an automated mini bioreactor platform that enables parallel cultivations in the milliliter scale with online monitoring and control, well-controlled conditions, and advanced feeding strategies similar to industrial processes. Automated Conditional Screening of Multiple Escherichia coli Strains in Parallel Adaptive Fed-Batch Cultivations Modelling concentration gradients in fed‐batch cultivations of E. coli – towards the flexible design of scale‐down experiments Application of Continuous Culture Methods to Recombinant Protein Production in Microorganisms Band

This study explores organic hydroponic cultivation as a sustainable alternative to chemical fertilizers amid global supply challenges. With rising costs and the depletion of conventional nitrogen sources, organic liquid fertilizers are gaining attention for their microbial enrichment processes (MEP) that convert organic matter into plant-accessible nutrients. This

- Used Man Double Decker Buses For Sale

- Using The Emulator Without A Disc Drive

- Used Clothes For Sale In Nottinghamshire

- Users Can’T Access Samsung Music From Android Auto Screen

- Used Minivans For Sale In Brantford, On

- Used Bmw X5 For Sale Near Me | Used BMW X5 Under $10,000 for Sale Near Me

- Using Splunk To Monitor Usb Removable Storage Devices

- Usk Altersfreigabe Für Der Herr Der Ringe : Die Gefährten

- Utc To Ist Ist To Dubai, United Arab Emirates

- Userbenchmark: Nvidia Gtx 780M Vs 980M

- Using Comparable To Compare Objects And Sorting Them In A Treemap

- Uss Bonhomme Richard Westpac Cruise Book 2007

- Uvex Rush Visor Velohelm Mit Visier