The Fundamentals Of Cathodic Protection

Di: Ava

Recent publications have ascribed the mechanism of cathodic protection (CP) in soils to the development of passivity at the steel surface. This view has, in turn, prompted discussion on the need to re-evaluate the long-established criteria for protection.

The Fundamentals of Cathodic Protection Measurements

What is the NACE CP 1 Cathodic Protection Course Manual? The NACE CP 1 Cathodic Protection Course Manual is a comprehensive document designed to accompany the CP 1 training course. It covers fundamental principles of cathodic protection, system components, testing procedures, and safety considerations. The manual is structured to facilitate both Cathodic protection was therefore neglected for 100 years, after which it began to be used successfully by oil companies in the United States to protect underground pipelines.2 It is interesting that the first large-scale application of cathodic protection by Davy was directed at protect-ing copper rather than steel. Cathodic protection fundamental concepts lie in simple electrochemistry. Metals tend to corrode while in contact with an electrolyte—water, soil, or seawater—developing anodic and cathodic regions on their surfaces.

The compilation is divided into four groups for both cathodic and anodic protection with and without a limitation of the protection range to more negative or more positive potentials respectively. What is the NACE CP 1 Cathodic Protection Course Manual? The NACE CP 1 Cathodic Protection Course Manual is a comprehensive document designed to accompany the CP 1 training course. It covers fundamental principles of cathodic protection, system components, testing procedures, and safety considerations. The manual is structured to facilitate both This comprehensive handbook covers all aspects of cathodic protection in terms of both practice and theory.

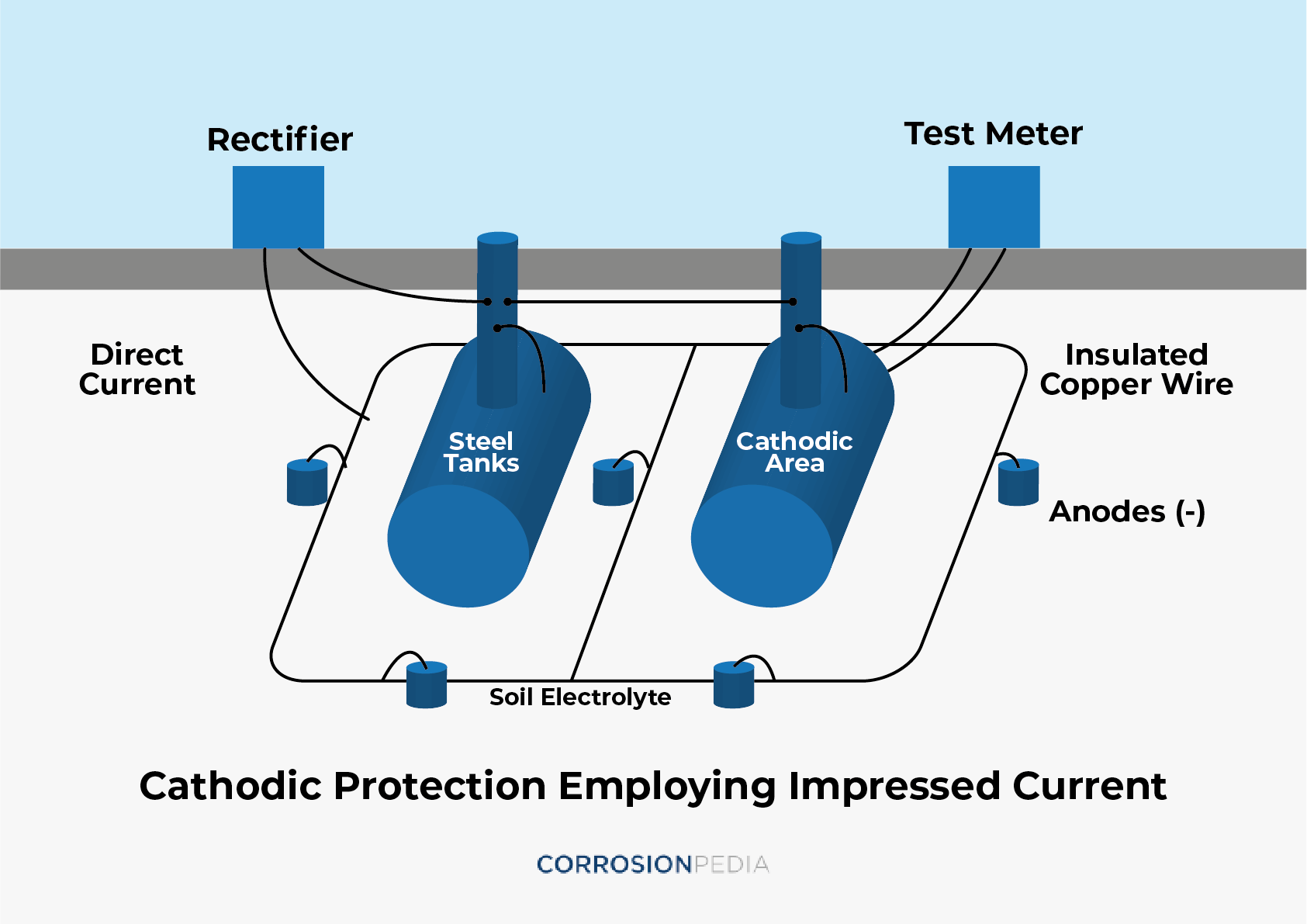

The document discusses cathodic protection methods for corrosion control. It describes two main types of cathodic protection – sacrificial anode and impressed current. Sacrificial anode uses more reactive metals like zinc or aluminum as anodes, while impressed current uses an external DC power source and insoluble anodes like graphite. Common applications include protecting

100_Fundamentals_of_Cathodic_Protection – Free download as PDF File (.pdf), Text File (.txt) or read online for free. The document discusses the significant costs of corrosion in the U.S. and the potential savings through modern corrosion control technologies, specifically focusing on cathodic protection. It details the mechanisms of corrosion and cathodic protection systems, including

There are also helpful appendixes that explain the fundamentals of underground corrosion, basic principles of cathodic protection, tables of properties of metals, and attenuation equations. If you’ve ever worked with cathodic protection remote monitoring units, other surveying instruments, chances are you’ve seen a variety of measurement specifications. Understanding these terms and their implications is key []

Understanding the Fundamentals of Corrosion and Cathodic Protection: Corrosion is an electrochemical process where a metal reacts with its environment, typically losing electrons and dissolving into solution. FUNDAMENTALS OF CATHODIC PROTECTION FOR MARINE SERVICE This report at first discusses in fundamental terms the nature of galvanic corrosion and electron flow, and then examines the behavior of dissimilar metals in a sea water electrolyte, and of how applied currents can protect steel surfaces.

There are also helpful appendixes that explain the fundamentals of underground corrosion, basic principles of cathodic protection, tables of properties of metals, and attenuation equations.

Cathodic protection is an essential method used to safeguard various types of infrastructure from corrosion. Whether it’s pipelines, storage tanks, or bridges, it plays a crucial role in extending the lifespan of these structures and ensuring their safe operation. In this comprehensive guide by LPS, we’ll explore the fundamentals of cathodic protection, its

Cathodic protection should be considered, possibly in conjunction with other forms of corrosion control such as the application of protective coatings, wherever the system is exposed to an aggressive environment in such a manner that cathodic protection is technically and ‚Cathodic Protection‘ published in ‚Electrochemistry and Corrosion Science‘ Cathodic protection is the electrical solution to the corrosion problem. In this article, the history of cathodic protection (CP) is traced, and the design fundamentals are developed, including the three components of a corrosion system, the three elements of an electric circuit, and the three configurations causing potential difference. CP is the process of forcing a metal to be more

What is the NACE CP 1 Cathodic Protection Course Manual? The NACE CP 1 Cathodic Protection Course Manual is a comprehensive document designed to accompany the CP 1 training course. It covers fundamental principles of cathodic protection, system components, testing procedures, and safety considerations. The manual is structured to facilitate both Cathodic protection is a critical component of corrosion mitigation. AMPP’s Cathodic Protection Program is the only program of its kind and an industry standard that provides students with the theoretical and practical fundamentals for testing, evaluating, and designing both galvanic and impressed current cathodic protection (ICCP) systems. CP systems are used across a Cathodic protection (CP) is a method of preventing corrosion of a metal surface by making it the cathode of an electrical circuit. Without getting too technical and without math, this article

What is the NACE CP 1 Cathodic Protection Course Manual? The NACE CP 1 Cathodic Protection Course Manual is a comprehensive document designed to accompany the CP 1 training course. It covers fundamental principles of cathodic protection, system components, testing procedures, and safety considerations. The manual is structured to facilitate both Cathodic Protection in Piping: Preventing Corrosion | Explained by EPC LAND Corrosion is a major challenge in the piping industry, leading to failures, leaks, and costly repairs. But did you know Cathodic Protection (CP) can significantly extend the life of pipelines and structures? In this video, EPC LAND explains the fundamentals of Cathodic Protection, its

Cathodic Protection is an industrial technique for controlling metallic corrosion that occurs in the Anode by oxidation and metal is lost, whereas in the cathode protection occurs by the reduction reaction. Cathodic Protection Fundamentals: Math & Electricity eCourse Walk into the cathodic protection classroom or field with a strong math, electricity, and chemistry foundation gained from this course. This course provides a thorough review of basic math, chemistry, and electrical fundamentals through step-by-step examples, self-study practice problems, and downloadable Corrosion, causes of corrosion current, and aspects of cathodic protection are explained; application of coatings and cathodic protection systems should always be economically justified; this requires thorough investigation in analyzing expected cost of

FUNDAMENTALS An introductory course in the fundamentals of corrosion and pipeline corrosion control, to help persons with little or no experience in the field understand why underground pipeline corrosion control is so important. Topics include basic corrosion, coatings, cathodic protection and potential measurements. This combination of protective coating and cathodic protection is used on virtually all immersed or buried carbon steel structures, with the exception of offshore petroleum production platforms and reinforced concrete structures. Fundamentals of Cathodic Protection This 5-day Cathodic Protection System in the Oil & Gas Industry training course is designed to equip delegates with comprehensive knowledge and practical skills in corrosion prevention using cathodic protection systems covering the fundamental principles of corrosion, the mechanisms and types of CP systems, essential design considerations, system components, and field

1.3 Cathodic protection. Cathodic protection is a method to reduce corrosion by minimizing the difference in potential between anode and cathode. This is achieved by applying a current to the structure to be protected (such as a pipeline) from some outside source. Explore the principles and applications of cathodic protection (CP) in preventing corrosion in steel and iron structures.

We are delighted to announce our live complimentary webinar “Cathodic Protection Systems: From Design to Approval as per International Standards”. During this webinar we will delve into the fundamentals of this crucial technique in safeguarding pipelines and structures against corrosion. Objectives To understand the fundamentals of CP design CP design principles,

- The Fennec Fox As A Pet | Fennec Fox What Do They Eat

- The Funniest Ryder Cup Moments

- The Fs Group Around The World _ War/No More Trouble feat. Bono

- The Hidden Harmony , The Hidden Harmony Is Better Than The Apparent Harmony.

- The Grafton Hotel Dublin Bei Hrs Günstig Buchen

- The Great Skipton Santa Fun Run

- Ju-On/The Grudge _ Ju On The Grudge Stream

- The Heroes Of Olympus Books Series By Rick Riordan

- The Etta At Shavano Park – The Etta Assisted Living At Shavano Park

- The Essential Skillset For The Age Of Ai

- The Gdpr And Privacy Shield : Answers to Privacy Shield FAQs provide guidance

- The Hilltop Pillbox _ A Closer Look at Historical Board Gaming’s Global War 1939

- The Growing Importance Of Nato’S Indo-Pacific Partners