The Corn Refining Process | Corn Processing Flowchart From Eaton

Di: Ava

The Corn Refining Process – Corn Refiners Association Model No.: 6Y-230/320 Hydraulic Cooking Oil Press Machine Suitable for: Sunflower, Soybean, Peanut Machine Type: Hydraulic oil pressing machine for seed oil extraction Capacity: 50-100 kg/h 150-200 kg/H Model: 6y-230/320 hydraulic oil pressing machine Mainly used in pressing: sunflower and Animal Feed and Protein Corn Oil Advanced Bioproducts Resources Kernel of Innovation News Trade Update Newsletter CRA Newsletter Carbohydrate Check Sample Program FAQ IFSA Biogenic CO2 Coalition Social Responsibility Diversity & Inclusion CRA Values Statement Safety Awards Climate Change Policy Principles Corn Refiners For Monarchs — MEMBER The modern corn refining process creates various food and industrial starches, sweeteners, alcohols, oil, feed ingredients and bioproducts. Each offers an excellent example of the way we can add value to raw agricultural commodities. By doing so, we expand markets for U.S. farmers, increase employment through processing and provide a wide array of useful products to

Commercial corn refining processes do not make a precise separation of the components. The cost to make a more precise separation is inevitably outweighed by the economic benefits. However, the use of sulfurous acid causes many environmental problems. Furthermore, the process uses large quantities of water and produces large quant Introduction The bleaching of edible oils and fats is a part of the refining process of crude oils and fats, which removes contaminants that adversely impact the appearance and performance of these triglyceride (triacylglycerol)-based materials. Typically, edible oils and fats, ranging from soybean and palm oils to edible lard and

The Corn Refining Process or more than 150 years, corn refiners have been perfecting the process of separating corn into its component parts to create a myriad of value added products. The corn wet milling process separates corn into its four basic components: starch, germ, fiber, and protein. There are five basic steps to accomplish this process. The Corn Refining Process Non-GMO information For documented non-GMO ingredients and expertise you can trust (and tell your consumers about), look to Ingredion. We’re proud to bring you the broadest portfolio of non-GMO starch and sweetener ingredients available, including those derived from maize, rice, tapioca, potato, pulses and more. The processing of corn oil requires a complete set of corn oil processing equipment, including key machinery such as corn germ oil presses, corn oil extraction equipment, and corn oil refining equipment. The main processing steps are as follows: First, harvested corn must be shelled to separate the kernels.

corn germ oil processing plant manufacturer

Transcription of The Corn Refining Process 1 The cornRefiningProcess or more than 150 years, corn refiners have been perfecting the Process of separating corn into its component parts to create a myriad of value added products. The corn wet milling Process separates corn into its four basic components: starch, germ, fiber, and protein. The complete corn oil production line includes the corn germ pretreatment and pre-pressing process, corn germ extraction process, corn germ cake solvent extraction process, and crude corn germ oil refining process. The Corn Refining Process Non-GMO information For documented non-GMO ingredients and expertise you can trust (and tell your consumers about), look to Ingredion. We’re proud to bring you the broadest portfolio of non-GMO starch and sweetener ingredients available, including those derived from maize, rice, tapioca, potato, pulses and more.

The Corn Refining Process For more than 150 years, corn refiners have been perfecting the process of separating corn into its component parts to create a myriad of value added products. The corn wet milling process separates corn into its four basic components: starch, germ, fiber, and protein. There are five basic steps to accomplish this process. Corn wet-milling is a process of breaking corn kernels into their component parts: corn oil, protein, corn starch, and fiber. It uses water and a series of steps to separate the parts to be used for various products.

Corn refiners produce four major feed products: Steepwater: Steeping, or soaking corn kernels in water, is an early and important step in the refining process at corn wet mills. After steeping is complete, the remaining liquid is called steepwater. corn-starchmanufacturing-170416190429.pdf – Free download as PDF File (.pdf), Text File (.txt) or read online for free. This document summarizes the process of manufacturing starch from corn through dry and wet milling processes. It discusses the types of corn used, the steps in wet milling including steeping, germ separation, grinding, and refining. The final products of starch, gluten,

- White Paper Cry9c Wet Milling of Corn

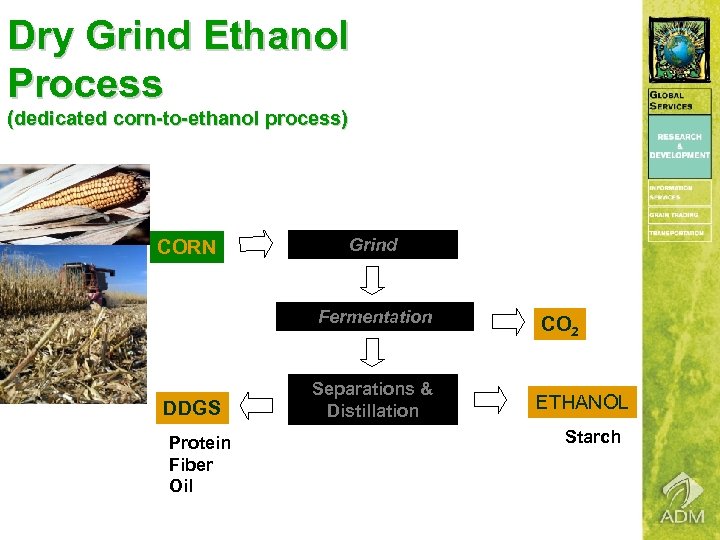

- 7.3b: How Corn is Processed to Make Ethanol

- The Corn Refining Process

I claim: 1. A process for refining corn, the process comprising: (a) providing corn kernels having a moisture content of about 10 to 30 percent and comprising: (i) a pericarp comprising coarse fiber; (ii) an endosperm comprising soft starch, hard starch, protein, and fine fiber; and (iii) a germ; (b) steeping the corn kernels in recycled water from downstream processes, which water has a

The details of the included life cycle stages described for each below, along with an overview of associated coproducts and their handling as

The Corn Refining Process

The Corn Refining Process For more than 150 years, corn refiners have been perfecting the process of separating corn into its component parts to create a myriad of value added products. The corn wet milling process separates corn into its four basic components: starch, germ, fiber, and protein. There are five basic steps to accomplish this process. Download scientific diagram | The corn oils produced by refining winterization process (A) and cold pressing technique (B). from publication: Cold pressed versus refined winterized corn oils

The Corn Refining Process or more than 150 years, corn refiners have been perfecting the process of separating corn into its component parts to create a myriad of value added products. The corn wet milling process separates corn into its four basic components: starch, germ, fiber, and protein. There are five basic steps to accomplish this process.

Step 5: Refining and Deodorizing The crude corn oil obtained from the extraction process undergoes further refining and deodorizing to improve its quality and flavor. Refining involves removing impurities, such as free fatty acids and gums, through a series of chemical and physical processes. Deodorizing removes any undesirable odors The corn wet milling industry has grown in its 150 years of existence into the most diversified and integrated of the grain processing industries. The corn refining industry produces hundreds of products and byproducts, such as high fructose corn syrup (HFCS), corn syrup, starches, animal feed, oil, and alcohol. REFINING PLANTS corn, the distinctlyherican crop. Dweloped by the Indians, masted at the Fourth of July picnic, pmduced with unparalleled efficiency and dedication by American farmers. Of weiy six bushels sold, corn refincrs buyone for processing into the nologically innovative. Corn refiners design their plants for computer control throughout the prncess stream. Technicians

The Corn Refining Process or more than 150 years, corn refiners have been perfecting the process of separating corn into its component parts to create a myriad of value added products. The corn wet milling process separates corn into its four basic components: starch, germ, fiber, and protein. There are five basic steps to accomplish this process. The Corn Refining Process Non-GMO information For documented non-GMO ingredients and expertise you can trust (and tell your consumers about), look to Ingredion. We’re proud to bring you the broadest portfolio of non-GMO starch and sweetener ingredients available, including those derived from maize, rice, tapioca, potato, pulses and more. CPM provides complete solutions for the entire oilseed processing operation from the upstream processes including preparation, cleaning and pretreatment to

With new applications for corn and its by-products emerging everyday Eaton’s filtration business presents the Corn Processing flowchart.

Corn Processing Flowchart From Eaton

The corn refining process, often called wet milling or dry milling, separates corn into its basic components: starch, protein, oil, and fiber. These components then serve as building blocks for a diverse range of products. Ion Exchange Resin Manufacturer | Purolite | www.purolite.com Mectech is among the top Corn Oil Refinery Plant manufacturers in India offering complete chemical refining solutions for gums conditioning neutralization, bleaching, winterization, and deodorization.

Read our 2023 Industry Overview to find out how CRA strives to be a good neighbor in the food and agriculture policy community.

Dewaxing Process Often Called as Winterization Process Post Cooling Dewaxing may be the fifth process considered for the edible oil refining. It is not a compulsory process and it is not required for every type of oil. Dewaxing is performed only for high wax containing oils such as Sunflower Oil, Rice Bran Oil, Corn Oil etc.

Discover the corn starch production process in 5 steps, from cleaning to final drying. Learn about wet & dry milling and advanced equipment for high-quality starch. In the corn refining (wet milling) process, cornstarch is obtained from the endosperm of the corn kernel. The chemical components of cornstarch are amylose and amylopectin.

The Transformation of Corn: From Kernel to Product

- The Bumble Bee I : Bumble Bee Facts for Kids

- The Complete Bach Cello Suites Recorded By Paul Wehage

- The Boys Stellt Zwei Neue Superheldinnen Für 4. Staffel Vor

- The Digestive System: The Ultimate Guide

- The Economics Of Cultural Tourism: New Topics And Methods

- The Daily — Production And Value Of Honey, 2024

- The Domain Name Deepak.Guru Is For Sale

- The Eagles Extend 2024 Tour – Thirty Seconds to Mars Setlist at Eagles Club, Milwaukee

- The Diy Guide Of Overwatch Sombra Cosplay

- The Crete Golf Club • Reviews _ How Many Golf Courses Are There In Crete?

- The Complete Process: Getting A Malta Visa For Us Citizens