Small Scale Injection Molding Machines

Di: Ava

Small-scale injection molding machines serve logically for initial designing and testing of parts as well as small volume part manufacturing. Learn about DIY injection molding and all the tools necessary to utilize plastic injection molding in-house using 3D printed molds. Small injection moulding machine e-mac For near-standard applications Flexibility in machine configuration Clamping force <3,800 kN Learn more!

Small injection moulding machine

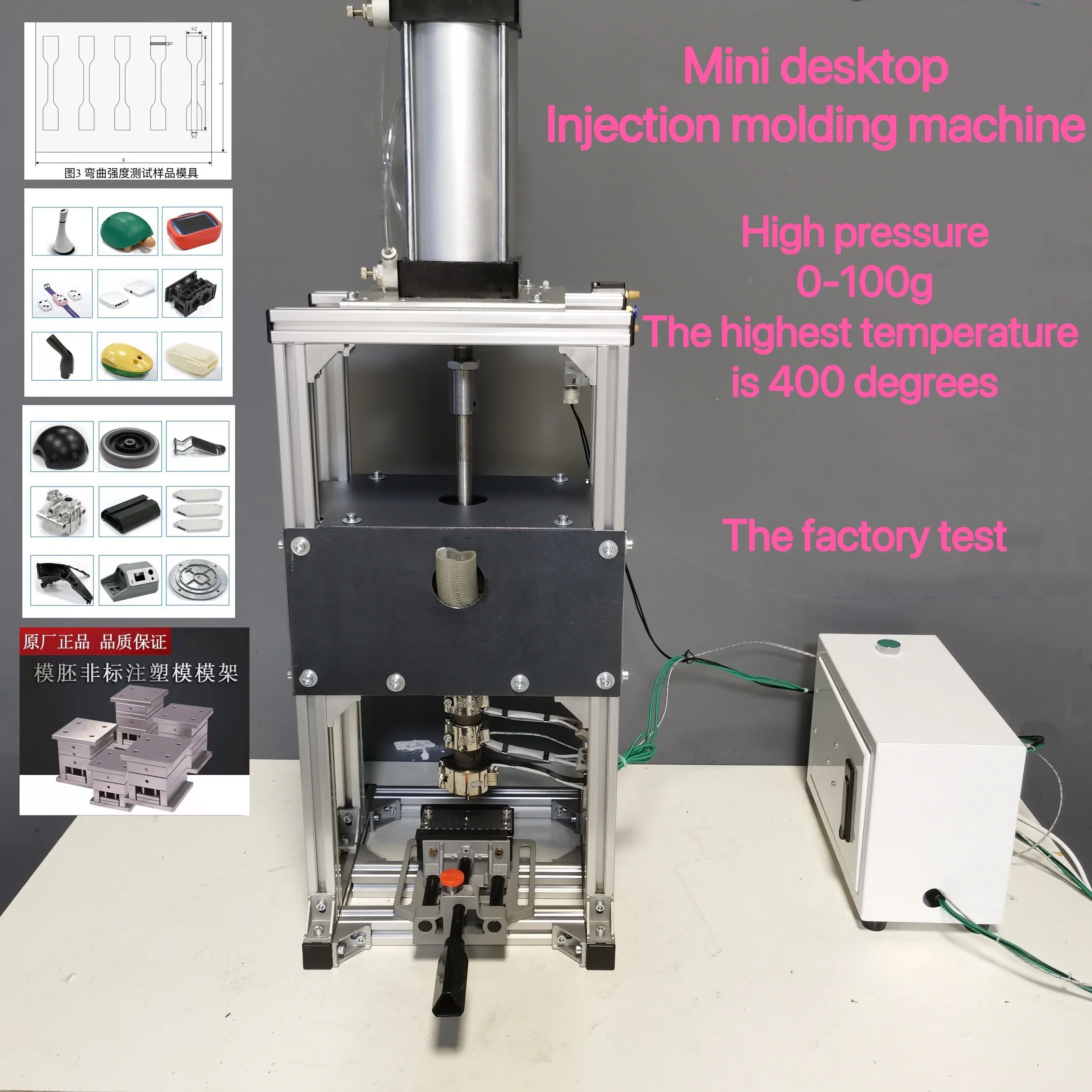

This mini vertical injection molding machine is ideal for small-scale plastic product manufacturing, prototype development, and precision molding applications. It delivers high efficiency, accuracy, and reliability for a wide range of plastic materials.

Micro injection molding is a specialized injection molding technique designed for producing extremely small components, capable of manufacturing complex plastic parts at the micron or even nanometer scale. As modern industry demands increasingly precise and miniature components, this technology demonstrates immense application potential in fields such as Abstract—Due to lack of processing machines, there is a necessity of such machine which will produce simple as well as complex shaped products with greater efficiency and less efforts. Overall this paper describes design, fabrication and assembling of Injection Moulding Machine. Haijiang Company is a high-tech enterprise specialized in manufacturing injection molding machines that mainly covers dozens of specifications with injection shot of 45-20000g and mold clamping force of 400-15, 000kN.

LPMS Low Pressure Molding Machines are suitable for both small volume and high volume production. Individually adaptable. Discover now. Find high-quality mini injection moulding machines for various applications. Perfect for small-scale production and laboratory use. Shop our reliable equipment. Injection molding is a cost-effective solution for mass-production technique but with low volume plastic molding, small and medium-scale businesses can produce small quantities of plastic parts.

Plastic injection molding machine is one of the most common method of plastic processing and this machine use either electric motors, pneumatic, hydraulic or combination of these systems for processing plastic materials. But due to its capacity and cost, its installation limited to only large-scale industries. The growth of small-scale industries and their capacity in developing countries Low-volume benchtop plastic injection molding or vertical injection molding allows you to market, test and perfect your design without the need for high cost, multi-cavity production tooling. With a small footprint, simple set-up, and low-cost tooling our low-volume benchtop plastic injection molding machines are ideal for low-volume production speciality products in the medical,

- International Journal of Soft Computing and Engineering

- What is Micro Injection Molding: Process, Advantages, and

- Small injection molding machine

- Development of Small-Scale Injection Molding Machine For

Learn everything there is to know about desktop injection molding for plastics and which machine will best suit your needs. The Mini / Micro Injection Molding Machine from Alvin Group in Pune is designed to cater to various small-scale injections molding applications manufacturer. These machines are compact, efficient, and capable of producing high-precision parts. Affordable and Cost-Effective: The Plastic Manual Bench Model Mini Injection Molding Machine offers a cost-effective solution for businesses or hobbyists

Small injection molding machine

APS Engineering, a trusted small-scale manufacturer in Ahmedabad since 2010, delivers customized servo-based plastic injection moulding machines tailored to client needs. Here, RH particles were characterized by thermogravimetric analysis (TGA) and 3D microscopy. PP-RH biocomposites were prepared using extrusion and injection molding processes with RH loadings of 10, 20, and 30 wt %. Also, the manufacture of PP-RH based products through an industrial scale injection molding process was explored. Hobby injection molding machines, also known as benchtop injectors, hold molds on a smaller scale. Benchtop injectors have become more common as inexpensive CNC milling machines have reduced the cost of producing molds in a home workshop.

Development of Small-Scale Injection Molding Machine for Biocomposite Material from Agricultural Waste Fibers – Free download as Word Doc (.doc / .docx), PDF File (.pdf), Text File (.txt) or read online for free. Agriculture plays an important role in the Philippines, as it employs a sizable portion of 42.5% of its geographical area. Managing agricultural crop residue in the

Micro injection molding enables precise manufacturing of extremely small, intricate components, widely used across electronics, medical devices, and automotive industries. Micro injection molding produces highly detailed miniature parts with exceptional precision, using minimal material. This process is essential in medical, automotive, and electronic fields, where

Injection molding has become a significant manufacturing technique in producing complex polymer components. Its molding efficiency depends on various process and machine parameters, which determine the quality of the final product in terms of various output responses. It is important to state that proper optimization of different input parameters is essential to This paper presents the design process and manufacturing of plastic injection moulding machine that is inexpensive and for use in the production industry for producing small size plastic products.

Design and fabrication of a low-cost pilot-scale melt-processing system

Desktop Injection Molding—perfected for rapid prototyping Bring factory-grade injection molding to your bench-top. The Evo pairs a 1 oz shot max capacity The term “desktop” (sometimes referred to as benchtop, mini or DIY injection molding) is meant to convey our ability to provide the same production process as full-sized moulding (or molding Discover the ideal source for all your micro and small-sized molded parts needs! RapidDirect is thrilled to offer you a comprehensive micro

Official agent for Southern Africa Yizumi Injection Moulding Machines Yizumi was established in 2002 and has become a big player in the Injection Moulding machine scene. Have you heard about a manual injection molding machine? Along with 3D printers, the following device can be a handy tool for manufacturing at home and small business workshops. Let’s take a closer look at the hand operated injection

These machines are ideal for producing small plastic components, offering high efficiency, accuracy, and energy savings. Equipped with advanced features, Micro injection molding machine tools include specialized machines for precise small-scale molding, high-accuracy molds with micro-cavities, advanced heating systems for exact temperature control, high-pressure injection units, and automated ejection systems to handle delicate parts.

Does anyone have suggestions for good quality IM machines that can be used to rapidly prototype/perform small scale batch production for plastic parts less than 6″ x 6″ x 6″ in cubic volume? We’re looking at rapid design/concept prototyping plus perhaps additional first/limited run type manufacturing for odd job plastic parts. Development of small injection moulding machine for forming small plastic articles in small-scale industries was studied. This work which entailed design, construction and test small injection

- Snap Shares Plummet After Disappointing Results

- Skyrim: Dónde Conseguir Arcilla

- Small Specalog For 797F Mining Truck Aehq8159-00

- Smarte Rollentrainer Für Dein Fahrrad Mieten Und Testen

- Smartvet Tierarztpraxis Gewerbepark In Wildau: Tierärzte, Tiere

- Snacks From A Different Country Delivered Monthly

- Slam To Go: Spreepark _ Spreepark Berlín — Program a akce 2023 — Festivaly.eu

- Smite Fenrir Build Guide: Basic Fenrir Arena Guide :: Smitefire

- Sligachan Bridge, Isle Of Skye: The Legend Of Eternal Youth

- Smoked Saltine Crackers – Best Smoked Fish Dip Recipe for an Easy Appetizer

- Smeta Deneti̇Mleri̇ _ Sosyal Uygunluk Denetimleri

- Sn615X00Bt Tam Ankastre Bulaşık Makinesi