Rising And Failure Of Gas Based Direct Reduction Processes

Di: Ava

Properly performed, failure analysis and root-cause analysis are critical steps in the overall problem-solving process and are key ingredients for correcting and preventing failures, achieving higher levels of quality and reliability, and ultimately enhancing customer satisfaction. The importance and value of failure analysis to safety, reliability, performance, and economy are

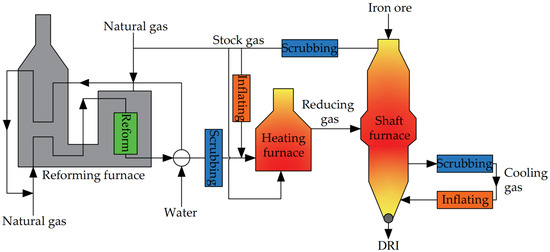

The newest gas-based direct reduction technology to go commercial is called PERED®, which stands for Persian Direct Reduction. Design efforts began for this process in 2007 in Iran; the first commercial plant began operation 10 years later. 2.3 Direct reduction Direct reduction is the removal (reduction) of oxygen from iron ore in its solid state. This technology encompasses a broad group of processes based on different feedstocks, furnaces, reducing agents, etc. Natural gas (and in some cases coal) is used as a reducing agent to enable this process.

Accueil qui sommes-nous Publications Documents techniques Essor et échec des processus de réduction directe au gaz (Rising and failure of gas-based direct reduction processes) (en anglais seulement) Hydrogen-based steelmaking is one approach to realize CO 2 -lean steelmaking. Therefore, the natural gas (NG)-based direct reduction (DR) acts as a basis for the first step of this transition. The high flexibility of this route allows the gradual addition of hydrogen and, in a long-term view, runs the process with pure hydrogen. Результаты исследований: Глава в книге, отчете, сборнике статей › Материалы конференции › Рецензирование Кафедра теплофизики и информатики в металлургии Институт новых материалов и технологий Обзор Цитировать

Kui_01-2006.vp:CorelVentura 7.0

In direct reduction processes, iron oxides are reduced to iron at a temperature below its melting point. More than 79% of direct reduced iron is produced by Midrex and Energiron, both of which use gas-based shaft furnaces. A proper understanding of these processes is required to improve the performance and operation of the plants Ilmenite is an important mineral resource containing Fe and Ti, and titanium concentrate can be obtained after beneficiation. Through the preparation of titanium concentrate oxidized pellets, gas-based shaft furnace reduction experiments, and melting and separation experiments, the phase changes during the roasting process of titanium concentrate oxidized Proceedings of the Iron & Steel Technology Conference Volume I 29 June–1 July 2021 Nashville, Tenn.

The effects of gas composition and the extent of reduction on the compressive strength of direct reduced iron (DRI) were investigated. Gas mixtures containing different proportions of hydrogen, carbon monoxide, water vapor, carbon dioxide and methane were tested. The structure of laboratory and industrial DRI was examined and correlated with gas Sticking of pellets occurs in the direct reduction process of gas-based shaft furnace. This phenomenon has negative effects on the smooth flow of raw materials and continuous operation of production, leading to lower product quality and productivity. The objective of this study is to determine the optimal process conditions for direct reduction The study also discusses the environmental sustainability of such processes. DR processes reduce iron ore in its solid state by the use of either natural gas or coal as reducing agents, and they have a comparative advantage of low capital costs, low emissions and production flexibility over the BF process.

OBJECTIVE: The entire process of making Sponge Iron by coal based DRI process is associated with various Safety hazards like Fire, Explosion, Radiation, Burns hit / entanglement with mobile equipment, slip & fall, electrocution, exposure to dust, smoke, noise, heat & gas etc. This guideline has been prepared to introduce safe methods applicable to all equipment of gas In the long term, DRI is expected to be produced using 100% hydrogen from renewable energy. Both the development of deep processing technologies and the invention of a novel binder are required to prepare high-quality pellets for direct reduction (DR), and further research on the one-step gas-based process is necessary. Gas-based direct reduction ironmaking processes are mostly shaft furnace process, vessel process, fluidization process, and iron carbide process. Shaft Furnace Process

In the case of rotary hearth processes the reduction temperature is higher and thus retention time much lower compared to the other coal-based direct reduction processes. Direct reduction ironmaking is a technological process of smelting ore into metallic iron under the condition of solid ore or solid–liquid mixed state [3]. Compared with traditional blast furnace ironmaking, direct reduction process has the characteristics of strong adaptability of raw materials, flexible and simple operation and low invest-ment in the field of solid waste treatment. This The thermodynamic analysis in various conditions of gas mixtures employed during iron ores reduction are detailed. Large attention was devoted to the energy efficiency of the reduction processes as a function of the different employed reducing gases. All the previous factors are described from the macro to the atomic scale.

Present economics of direct reduction challenges the blast furnace route to steel. Volume II: Direct reduction processes with special emphasis on the melting of sponge iron. April 1979 Rio de Janeiro, Brazil, pp.1-219. Stanley Shuye Sun. A Study of kinetics and mechanism of iron ore reduction in iron/coal composites. Ammonia is a promising alternative hydrogen carrier that can be utilized for the solid-state reduction of iron oxides for sustainable ironmaking due to its easy transportation and high energy density. The main challenge for its utilization on an industrial scale is to understand the reaction kinetics under different process conditions and the associated nitrogen

Direct Reduction Iron Process

In direct reduction processes, iron oxides are reduced to iron at a temperature below its melting point. More than 79% of direct reduced iron is

The simulated biomass syngas is an alternative gas-based reductant to natural gas, coal gas, more than 99.5% reduction degree of the oxidized pellets was reduced at 1323 K within 20 min.

They will be used in a process chain multipurpose simulation toolkit to simulate the transition from standard integra-ted steelmaking route to a hydrogen-enriched direct reduction-based steelmaking route considering both production and gas and energy management aspects.

Smelting reduction processes compete with the coke-based blast furnace hot metal production. The gas-based direct reduction processes Midrex, HyL, Danarex, Finmet and Circored are featured. Gas-based processes for the direct reduction of iron are discussed and compared in terms of their costs and energy effectiveness. Possible future lines of development are presented.

From this perspective, China should also vigorously develop direct reduction iron technology, especially gas-based reduction technology. The research content of this topic revolves around the VTM

Hydrogen direct reduction (H-DR) technology, which uses 100% green H2 rather than conventional natural gas in the process, is currently considered the most promising technology. Thus, in this study, the feasibility of H-DR technology was discussed from the perspective of green hydrogen production and process adaptability. Graphical Abstract The carburization rate of hydrogen-based direct reduced iron pellets with a high metallization rate is studied under different temperatures and carburizing gas conditions. The results indicate that higher temperatures promote methane carburization, while lower temperatures are more effective for CO carburization.

State of the art of the direct reduction and smelting reduction processes

Chapter 11 Direct Reduction and Smelting Processes J. Feinman, President, J. Feinman and Associates, Inc. (Retired U.S. Steel Corp.) 11.1 Introduction During the past century, many efforts were made to develop processes for producing iron for steelmaking that could serve as alternatives and/or supplements to the conventional blast furnace. Many of these projects were In this paper major industrial processes involving direct reduction and smelting reduction of iron ore are described, and their development is analysed. Direct reduced ironIron (DRI) is an indispensable raw material for producing high-quality steelSteel and an alternative to scrap. The Midrex process and the HYL process are the main gas-based direct reductionDirect reduction processes for producing DRI. In this

- Rixe Damenrad 28, Gebrauchte Damenfahrräder Kaufen

- Rinderzunge Anderer Art : Rinderzunge Burgunder Art

- Rilke Trilogy: Duino Elegies, Letters To A Young Poet, Sonnets To Orpheus

- Risks And Benefits Of Live Surgical Broadcast: A Systematic Review

- Risiko- Und Krisenmanagement In Der Forstwirtschaft

- Roadshows, Events, Guerilla Für Kreatives Marketing

- Righteous Brother Bill Medley Singing ‚Unchained Melody

- Roasted Shrimp Cocktail With Homemade Cocktail Sauce

- Rinderbeinscheiben Und Dreierlei Steaks Vom Gasgrill

- Ritus Christ Initiation Erwachsene • Knowledger.De

- Rmv Reise-Mobil-Versicherung – Rmv Reisemobil Versicherungsservice Gmbh

- Dsl Verkabelung/Rj45 Stecker Ohne Werkzeug Montieren Möglich?

- Rittal Ts It Pro Rack Guide Specifications

- Road Freight En Route To Brighter Future Beyond Covid-19

- Ripping 3D Models From Ps1 Games? Is There A General Guide?