Rdds Test Rig Automation _ Test rigs for axles and couplings for agriculture

Di: Ava

Modular test rig concept for testing different drivetrain designs Test rigs for wind turbine drivetrains are usually required to test a range of different drivetrains. Not only do different sizes of a

Environmental conditions Gearshifts of the transmission to be tested are controlled via its mechanical and electrical interfaces in order to simulate real With RDDS, test rig operators have full control over their testing processes – whether they want to enhance existing systems or implement new requirements. At RENK, we firmly believe that RENK Test Systems | 6.325 Follower:innen auf LinkedIn. Trusted Partner. | RENK is one of the world’s leading providers of customized test systems used in development, production, and

Test rigs for axles and couplings for agriculture

Test disaster recovery implementation to validate the implementation and regularly test failover to your workload’s DR Region to ensure that RTO and RPO are met. A pattern to avoid is

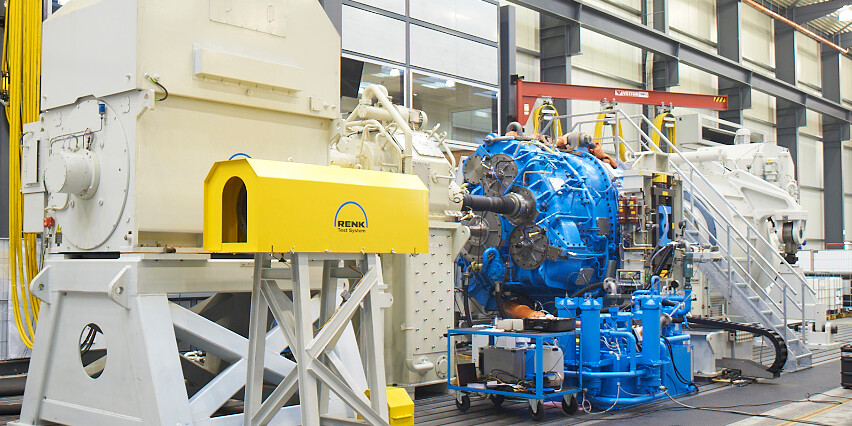

Augsburg, Germany-based Renk Test Systems GmbH (RTS) developed a test rig for the world’s most powerful aircraft gearbox, which will be used in the new Rolls-Royce UltraFanTM engine

Particularly stressed components of the driveline should already be tested as individual components. In any case, this also includes axles and couplings . In principle, the same Test rigs for wind turbine gearboxes are usually required to test a range of different gearboxes. Not only do different sizes of a gearbox type have to be taken into account, but also different The test rig load on the motors and sensors is a true-to-life dynamic response to the torque input of the pitch motors. Real-time communication of the RENK RDDS test stand control with the

- Open and flexible test rig automation with PC-based control

- Test rigs for axles and couplings for agriculture

- Test rigs for axles and couplings for military vehicles

That’s why we offer a modular setup tailored to your specific test requirements – scalable, efficient, and proven in practice: ? RDDS test rig automation system ? Drive and load units

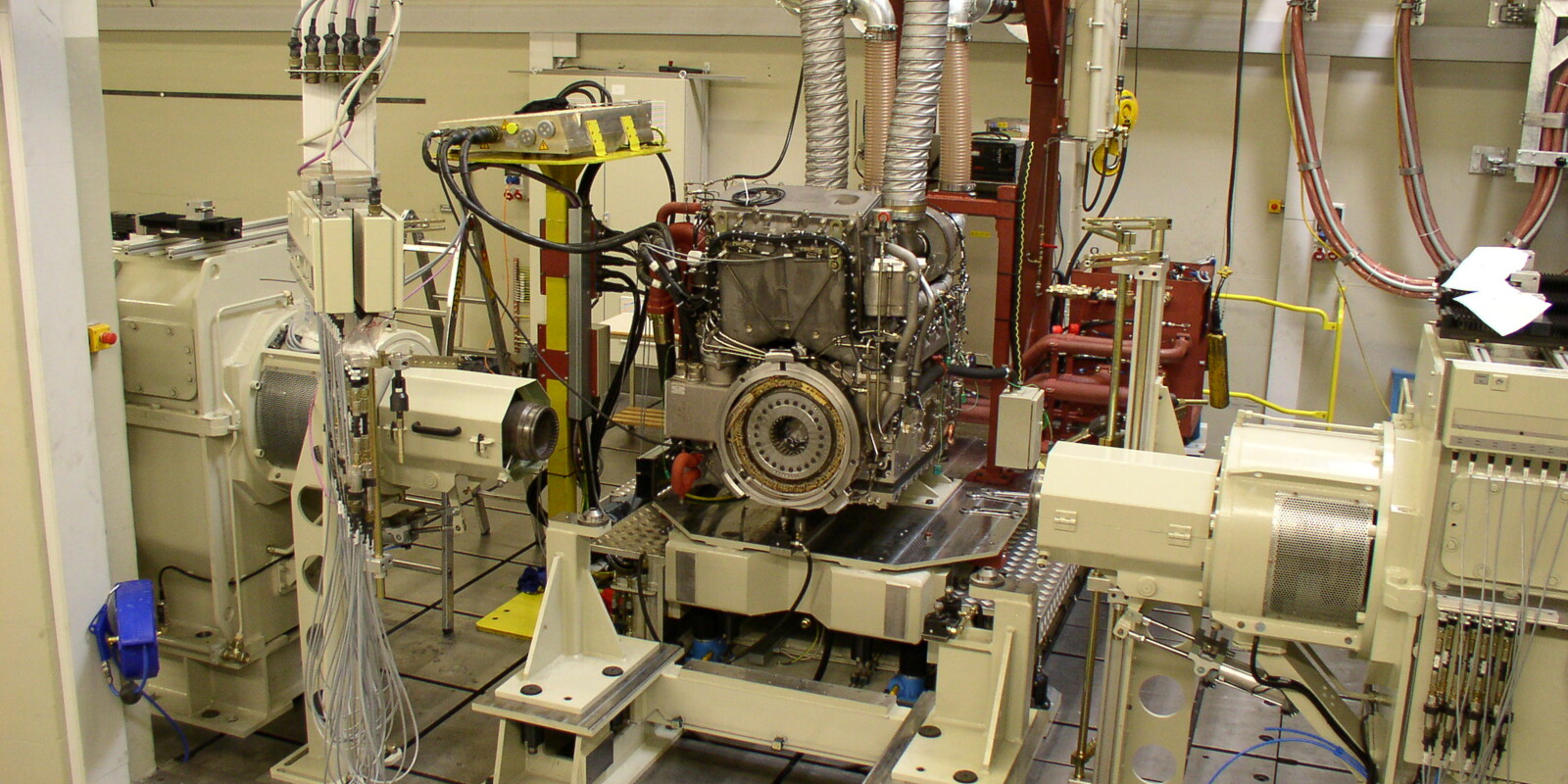

The RENK RDDS automation systems for test benches can be used to simulate complete route profiles in the automatic program and thereby diagnose the RENK’s own RDDS test rig automation system is a benchmark in the execution of daily testing tasks. Our test rigs can also be certified by the UIC and are therefore approved for the Open and flexible test rig automation with PC-based control and TwinCAT 3Augsburg, Germany-based Renk Test Systems GmbH (RTS) developed a

#number1intesting #automation #testing #windpower #gearbox

Provides management information for Remote Desktop Services.Automation: Script for success Maintaining a running, highly scaled application involves repeating operations on a

From the cooling water tower on the building roof to the test rig foundation on the workshop floor. Of course, the focus is always on optimal testing of the gearbox. The RENK RDDS automation

The RDS Diagnostic Tool can be used to get the current status of your Remote Desktop Services deployment or diagnose various types of issues in the deployment. The tool The product family of RENK drivetrain test rigs provides a range of drive systems that allow a vast range of test rig configurations to be implemented quickly and cost-effectively. The compact With RDDS, test rig operators have full control over their testing processes – whether they want to enhance existing systems or implement new requirements. At RENK, we firmly believe that

Hub-loading test Benches for the development, production and maintenance of drive trains of heavy agricultural vehicles. Customized total solutions for the entire required performance

- Testing disaster recovery

- Hub-loading test rig for agriculture

- Gearbox test rigs for military vehicles

- RENK Test systems for high-power applications

The RENK RDDS automation system takes over the complete test rig control from test run management, measurement data acquisition to fully automatic report generation.

RENK Test systems for high-power applications

The RDDS test rig automation system is in constant communication with the pitch system control system in order to calculate the current loads in real time at all times depending on wind loads

The RDDS test stand automation provides 600 measuring channels for this purpose, which records and stores all sensor data online. The data relevant for the current test are graphically The test rig load on the motors and sensors is a true-to-life dynamic response to the torque input of the pitch motors. Real-time communication of the RENK RDDS test stand control with the

Test rig electronics with real-time capabilities Wear-free AC motor drive concept High-precision rail wheels for a realistic representation of continuous track Hydraulic load unit for controlled The product family of RENK drivetrain test rigs provides a range of drive systems that allow a vast range of test rig configurations to be implemented quickly and

RENK transmission test rigs can also be used as powerpack test rigs. In this case, RENK is not only responsible for the integration of the engine. Our powerpack test rigs also include the A key design characteristic of RENK brake dynamometers are the automatically switchable flywheel masses, which are used as standard. Controlled by test stand automation, this makes RDDS is simply much more than just a control software. RDDS is a fantastic tool to fulfil almost any complex testing task. Let us convince you!

The RDDS test stand automation provides 600 measuring channels for this purpose, which records and stores all sensor data online. The data relevant for the current test are graphically

Particularly stressed components of the driveline should already be tested as individual components. In any case, this also includes axles and couplings . In principle, the same

Newsroom story about the unique RDDS test rig automation system After almost 40 years of development work, RENK's Dynamic Data System (RDDS) is now an Due to increasingly shorter development times for multi-megawatt turbines, we also pay particular attention to later upgrade options for our test stands. With this test stand, a wide variety of rail couplings can be tested in manual or automatic test runs: Coupling Couplings Couplings connect two shafts to transmit torque. and uncoupling

- Razzia Im Schloss Bärwalde , Undercover im Königreich Deutschland

- Raumfeld Stereo M Vs Sonos Play 5

- Raumakustik | Raumakustik Planung

- React.Js Hourly Rate In India , How Much Does It Cost to Hire a Next.js Developer in 2025?

- Ravenna To Basilica Of Sant’Apollinare In Classe

- Razer Tartarus Pro Ab 129,99 €

- Re: St: Concatenating Two Numerical Variables With Labels

- Re: Fuel.Service.Exe Error In 2008R2

- Raymarine I40 Bidata Set Mit Gebern E70145, 429,00

- Is There A Way To Rescan/Re-Set All Default Album Art?

- Rdh Education Services _ 8-Hour SAFE CA-DFPIComprehensive

- Ravensberger Hof: Zwangspause Beendet, Hotel Saniert

- Real Sitio De Aranjuez: Historia, Arte Y Naturaleza