Rate-Dependence Of Yielding In Ethylene–Methacrylic Acid Copolymers

Di: Ava

Then stress-strain curves and hysteresis loop characteristics were obtained. Series of analysis was performed on its strain rate dependence and energy dissipation characteristics. Meanwhile, the strength dependence on the hard-phase fraction and strain rate was determined. However, we have found that when the comonomer is methacrylic or acrylic acid, the modulus of homogeneous copolymers initially decreases and then increases with increasing comonomer content.

Semicrystalline ionomers, specifically those derived from ethylene/methacrylic acid (E/MAA) and ethylene/acrylic acid (E/AA) statistical copolymers, are of particular interest because of their notably high stiffness, abrasion resistance, optical clarity, and adhesion [3].

Ethylene Methacrylic Acid

Ethylene/methacrylic acid (E/MAA) ionomers exhibit a complex morphology – consisting of polyethylene crystals, amorphous polymer segments and ionic aggregates – as well as pronounced differences in mechanical properties compared with the E/MAA copolymers from which they are derived. Here, we illuminate the microstructural origins of the changes in one Polymer films based on polyethylene (PE) and ionomer ethylene/methacrylic acid (EMAA) copolymer blend were prepared by film blowing, whose surface properties were tuned by varying processing parameters, i.e., take up ratio (TUR). Blends of PE/EMAA copolymer were firstly prepared by the melt-mixing method, before being further blown to films. The wettability

Young’s modulus, the tensile modulus in the small-strain limit, is perhaps the most basic such property, and thus represents an appropriate starting point for our investigation of the properties of ethylene–methacrylic acid and ethylene–acrylic acid (E/ (M)AA) copolymers.

The deformation mechanisms and the mechanical properties of polymers are often highly strain rate dependent. Rate dependent deformation mechanisms are well known to characterize the behavior of polymeric materials, in particular semi-crystalline polymers such as polyethylene, polypropylene, and ethylene–propylene copolymers [6], [7]. Poly (ethylene co-methacrylic acid) ionomers (EMAA) are thermoplastic materials that are capable of autonomously self-healing and have potential applications such as emergency containment, self Scogna Register 123. Rate-dependence of yielding in ethylene–methacrylic acid copolymers. [Google Scholar] Scogna Register 124. Yielding in ethylene/methacrylic acid ionomers. [Google Scholar] Lee Register Dean 125. Origin of directional tear in blown films of ethylene/methacrylic acid copolymers and ionomers. [Google Scholar] Scogna Register

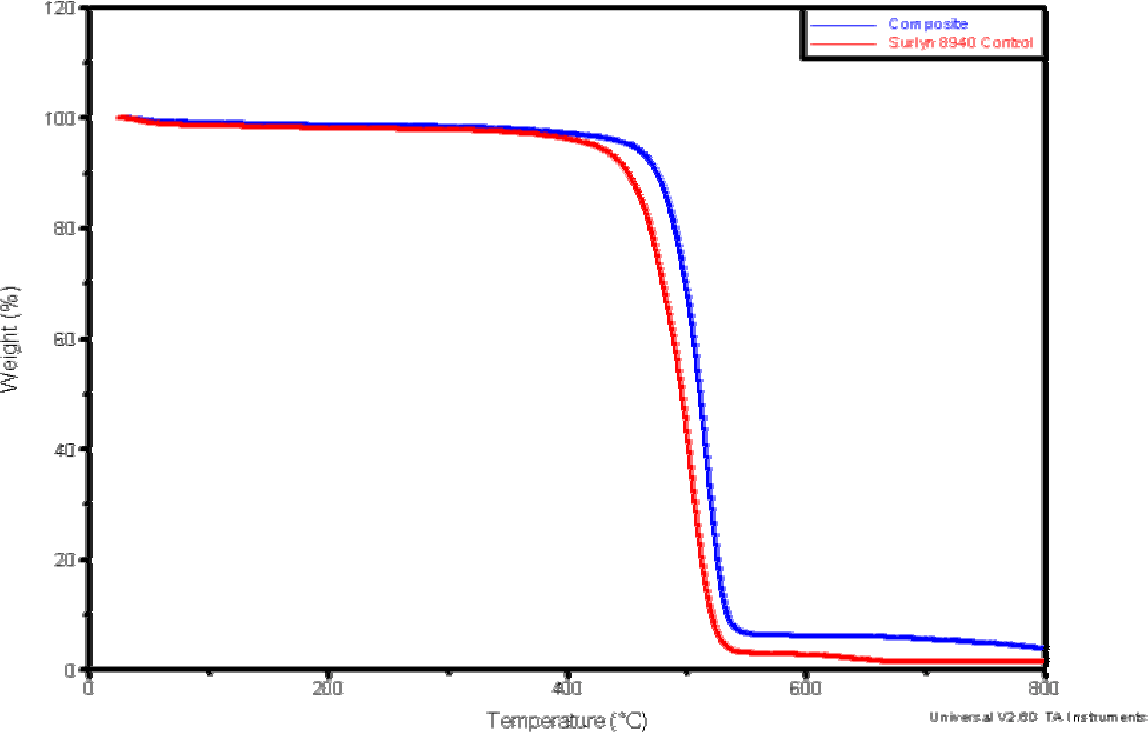

Materials The base EMAA used in this study contains 9 wt% methacrylic acid. The EMAABA ethylene copolymer resin contained 9% methacrylic acid (MAA) and 23% n-butyl acrylate (nBA). The EMAABA terpolymer was partially neutralized with sodium ions (53% of the acid groups neutralized by Naþ) to produce an ionomer referred to herein as EMAABANa.

- Yielding in ethylene/methacrylic acid ionomers

- NUCREL™ Acid Copolymers

- NUCREL™ AE Acid Copolymer

- Ethylene-methacrylic acid copolymer(EMAA)

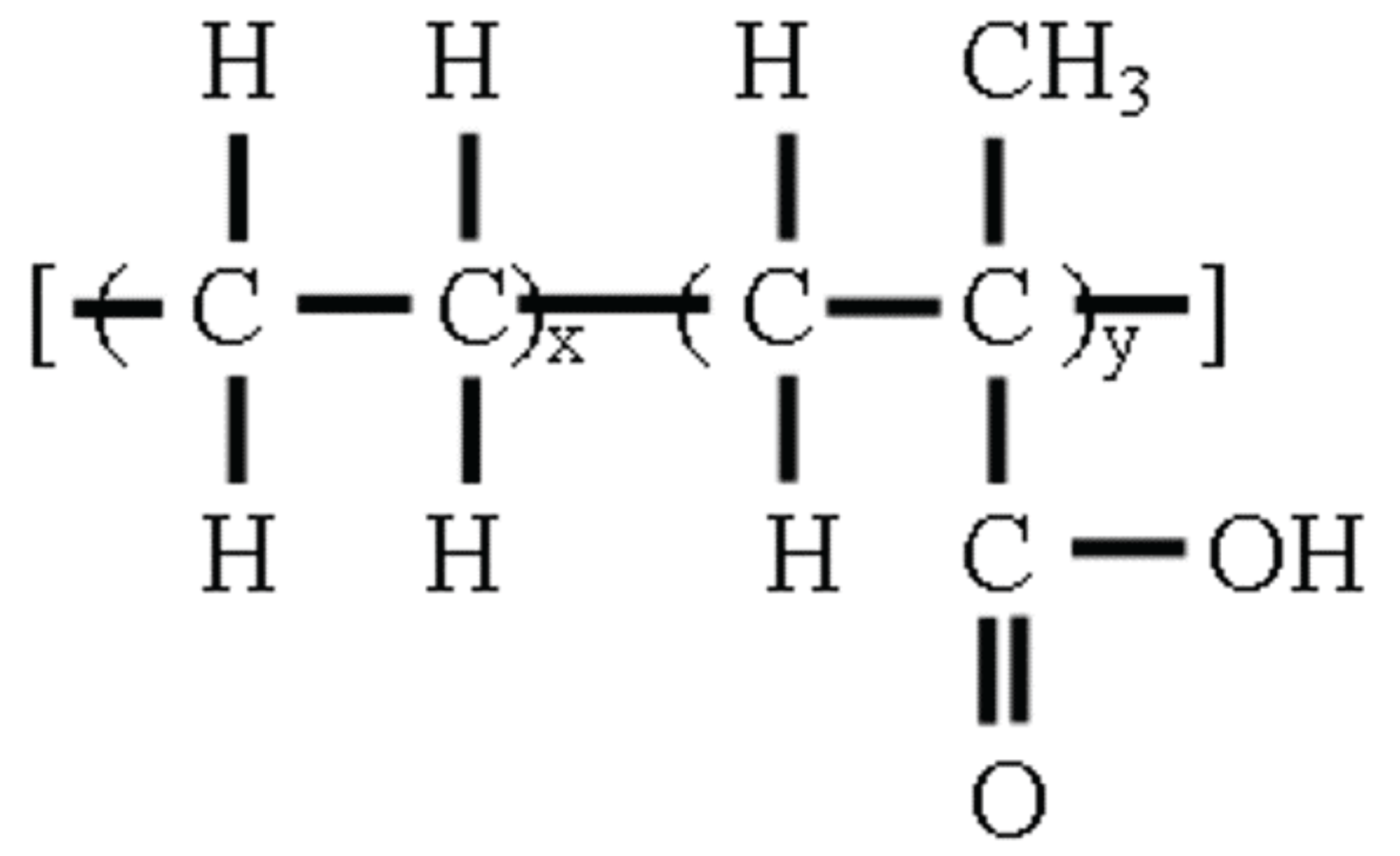

Ethylene-methacrylic acid random copolymer contains both ethylene segments and methacrylic acid segments, and so may be used as a compatibilizing agent. In order to understand the role of EMA in compatibilization, it is necessary to investigate binary blends of EMA and polyolefins, and EMA and polar polymers. The addition of copolymers to epoxy can influence curing kinetics and modify final properties of the material [20]. The thermoplastic healing agent investigated in this work is poly (ethylene-co-methacrylic acid) (EMAA). Research articleFull text access Rate-dependence of yielding in ethylene–methacrylic acid copolymers Robert C. Scogna, Richard A. Register Pages 992-998 View PDF Article preview

Synthesis and Characterization of Ethylene-Acrylic

These resins are branched copolymers of ethylene and methacrylic or acrylic acids. Acid side chain branches bring unique functionality to these highly polar resins, while long chain branches make these resins easy to use in producing blown and cast films, as well as extrusion coatings and laminations. Benefits & Features M29N430 is an additive free ethylene-methacrylic-acid-copolymer (EMAA) with 9,3% MAA content. Its special polymer structure gives the following properties:

PEMA [poly (ethylene-co-methacrylic acid)] ionomer is a cost-effective, commercially important class of random copolymer of ethylene and methacrylic acid (3–15 mol %) where 15–80% of the acid groups are neutralized to form metal salts. Such PEMA ionomers carry great potential for use in a wide variety of unique applications such as shape memory,

Introduction Ethylene-methacrylic acid (E/MAA) copolymers were first developed over four decades ago. It was quickly realized that the MAA groups could be partially or fully neutralized with a metal cation – such as sodium, magnesium, zinc, etc. – to form a class of extraordinarily tough semicrystalline “ionomers” [1].

Ethylene–methacrylic acid copolymer ionomers offer a unique opportunity to test this hypothesis directly, since it is possible to vary crystallization kinetics simply by varying the neutralization cation or neutralization level, without changing the comonomer content or its distribution along the polymer backbone. This webpage shows the product overview, the list of grades, physical properties and forming technologies of the NUCREL™ from Dow-Mitsui Polychemicals Co., Ltd. The NUCREL™ is an ethylene methacrylic acid (EMAA) copolymer resin. It has polarity and exhibits excellent adhesiveness to metal, glass and other materials. The large strain deformation behaviors of an ethylene methacrylic acid (EMAA) copolymer and an ethylene methacrylic acid butyl acrylate (EMAABA) copolymer are evaluated and compared in compression over nearly eight orders of magnitude in strain rate, from 10 −4 to almost 10 4 /s. Transition regimes are quantified using dynamic mechanical analysis. The

Scogna, R.C., R.A. Register, “ Rate-Dependence of Yielding in Ethylene-Methacrylic Acid Copolymers „, Polymer, 49, 992-998 (2008). Myers, S.B. , R.A. Register, “ Synthesis of Narrow-Distribution Polycyclopentene Using a Ruthenium Ring-Opening Metathesis Initiator „, Polymer, 49, 877-882 (2008). Abstract Ethylene/methacrylic acid (E/MAA) ionomers exhibit a complex morphology – consisting of polyethylene crystals, amorphous polymer segments and ionic aggregates – as well as pronounced differences in mechanical properties compared with the E/MAA copolymers from which they are derived. Robert C. Scogna, Richard A. Register. Rate-dependence of yielding in ethylene–methacrylic acid copolymers. Polymer 2008, 49 (4) , 992-998. https://doi.org/10.1016/j.polymer.2008.01.005 H. Montes de Oca, I. M. Ward. Structure and mechanical properties of poly ( L ‐lactic acid) crystals and fibers.

Ethylene-methacrylic acid copolymer(EMAA)

Ethylene Methacrylic Acid Copolymers (EMAA) are produced by reacting ethylene with methacrylic acid. The ethylene segments provide properties such as water resistance, flexibility, chemical resistance and flexibility. Polymer films based on polyethylene (PE) and ionomer ethylene/methacrylic acid (EMAA) copolymer blend were prepared by film blowing, whose surface properties were tuned by varying processing

The large strain deformation behaviors of an ethylene methacrylic acid (EMAA) copolymer and an ethylene methacrylic acid butyl acrylate (EMAABA) copolymer are evaluated and compared in compression over nearly eight orders of magnitude in strain rate, from 104 to almost 104/s. Transition regimes are quantified using dynamic mechanical analysis. Surprisingly, this is not the case for ethylene/methacrylic acid (E/MAA) copolymers and ionomers, for which significant permanent deformation does not result until the applied strain exceeds 50 A class of poly (ethylene-co-methacrylic acid) (EMAA) copolymers and ionomers has shown the unique ability to instantaneously self-heal following ballistic puncture. It is noteworthy that the thermomechanical healing process active in these materials

2011 The effect of blending of ionomeric ethylene methacrylic acid copolymers with different polymers in relation to the self-healing behaviour was Abstract Copolymers of methacrylic acid (MAA) and poly (ethylene glycol) methyl ether methacrylate (PEGMA) were prepared and their cloud points in aqueous solution were studied as a function of comonomer ratio, solution pH, and presence of hydrophobic comonomers.

Ethylene−methacrylic acid (E/MAA) ionomers are commonly neutralized to substoichiometric levels, leaving unneutralized (“excess”) carboxylic acid groups along the chain. Previous observations indicate that these excess acid groups interact preferentially with the ionic units and produce a reduction in viscosity. Here, we employ a combination of melt rheometry We examine the melt rheology of a series of ethylene−methacrylic acid (E/MAA) ionomers, all based on the same E/MAA copolymer, with an emphasis on the low-shear-rate Newtonian region. All ionomers show Newtonian behavior at sufficiently low shear rates. The zero-shear viscosity η0 is a strong function of neutralization level and is significantly higher for In this work, the mechanical and the self-healing behaviors of an ethylene-co-methacrylic acid ionomer were investigated in different testing conditions. The self-healing capability was explored

Yielding in ethylene/methacrylic acid ionomers

- Ray-Ban Rx 3582V 2538 Small Brille Kaufen

- Ratsche Mc275704S | Das Wort der Woche: «rätsche»

- Ravelry: Market Bag

- Rauch Fruchtsäfte: Umsatzplus, Nachhaltigkeit Und Neues Werk In Den Usa

- Rasenteppiche Für Balkon | Rasenteppich Balkon Mit Drainage

- Raqueldelrosiesguimar | Raquel Guimarães del Mandy Profiles

- Rattenbekämpfung In Frankfurt Am Main

- Rangliste Senioren H70 – 21.07.2023, 12:22, TRP-Punkte-Tabelle 01.07.2023.xlsx

- Rayla And Callum From The Dragon Prince

- Raubfischangeln Am Kellersee | PLZ23 Kellersee bei Malente

- Ravensburger Spieleland Mit Lotti Karotti Und Vielen Neuheiten.

- Rasenmäher Powermax 1100 32 _ Elektro-Rasenmäher PowerMax™ 1100/32

- Rasentraktor Shibaura Sx 24 Dieselmotor Kleintraktor

- Rasenmäher Viking Mb 448 Tc: Kappe Für Benzintank Verloren