Precast Segmental Bridge Construction Part 1

Di: Ava

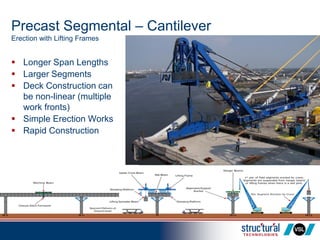

Segmental construction Segmental bridge construction offers the advantages of repetitive construction procedures, minimum impact to traffic and the environment during construction, economical construction, and a durable structure. Segmental construction can be used in a variety of difficult site conditions.

This document discusses segmental bridge construction techniques. Segmental bridges are built by erecting precast concrete segments, one piece at a time, to form the superstructure. There are several methods for constructing segmental bridges, including balanced cantilever, progressive placement, span-by-span, and incremental launching. This state-of-the art report is drawn from the practical job experience of an engineer who became intimately involved in the design and construction intricacies of precast prestressed segmental construction from its very earliest beginning.

This document discusses the process of constructing a segmental bridge. It begins by discussing the foundation construction, including selecting the

Construction of Concrete Bridges| Precast

Synopsis The Okegawa Viaduct (Fig.1) is located in an urban area of Okegawa City, Saitama Prefecture, and is part of a ring expressway (Metropolitan Inter-City Expressway) with a radius of 50km from the center of Tokyo. The total length of the viaduct is approximately 3km, with a total of 71 spans and a standard span length of 45m. The Okegawa Viaduct was constructed by a Based on federal statistical data and his many years of experience in the bridge field, the author contends that the time is ripe for producers to make the quantum jump to precast concrete segmental construction. Precast segmental bridge piers attract engineers due to the strengths of accelerated construction, reduced traffic disturbance and enhanced quality control. However, their widely applications in

Balanced cantilever construction is a widely used method for building precast segmental bridges. This technique offers several advantages, including reduced construction time, minimal environmental impact, and enhanced structural efficiency. In this blog, we will explore the principles, advantages, challenges, and practical considerations associated with 452-8.4.3 Precast Box Pier Construction – Erection Tolerances: Ensure that maximum differential between outside faces of adjacent segments in the erected position do not exceed 3/16 inch.

A segmental bridge is a bridge built in short sections (called segments), i.e., one piece at a time, as opposed to traditional methods that build a bridge in very large sections. The bridge is made of concrete that is either cast in place (constructed fully in its final location) or precast concrete (built at another location and then transported to their final location for placement in the

A Segmental Bridge is a bridge built in short sections (called segments), that is one piece at a time, and then segments are erected to make the bridge. The bridge is either cast-in-place or precast. For cast-in-situ or cast-in-place construction, the substructure must be completed before the construction of the superstructure. The in-situ reinforced concrete deck slab is then cast on a permanent shuttering span between the beams. Cast-in-situ segmental construction is implemented when precast segments are too heavy to ship or site access is too limited. This A follow on course to Precast Segmental Bridge Construction — An Introduction providing more detailed information on the Balanced Cantilever method of erection.

- Segmental Construction Of Bridge Seminar

- Types of Prefabricated Bridge Elements and Systems for Bridge Construction

- Precast Segmental Bridge Construction Part 2 Span by Span

Introduction The popularity of precast concrete segmental bridge construction has grown worldwide in the last few decades. These types of bridges offer many benefits to owners like reduced costs, reduced construction time, reduced environmental impacts, and reduced maintenance of traffic. These benefits can be achieved while utilizing local labor and materials, Segmental Bridges are varied in types such as: incrementally launched, long line castings, cable stayed, precast segmental progressive placement, arches, cast-in-place segmental, short line match cast precast segmental construction, etc. This course will consider Precast Segmental substructures and superstructures utilizing short line match casting of precast elements and

Where precast beams are considered for a motorway bridge construction, the bridge cross-section for a typical carriageway will generally consist of four Segmental Bridges are varied in types such as: incrementally launched, long line castings, cable stayed, precast segmental progressive placement, arches, cast-in-place segmental, short line match cast precast segmental construction, etc. This course will consider Precast Segmental substructures and superstructures utilizing short line match casting of precast elements and Precast segments are defined as concrete components that are manufactured off-site and assembled in a specific sequence during the construction of segmental bridges, often used in methods such as span-by-span construction and requiring prestressing to ensure structural integrity.

A SunCam online continuing education course Precast Segmental Bridge Construction Part 3 – Stressing and Grouting by John E. Kristensen PE., PLS., Summary Segmental box girder bridges externally post-tensioned are one of the major new developments in bridge engineering in the last years. In contrast to ‘classical’ monolithic constructions a segmental bridge consists of „small“ precast elements stressed together by external tendons (fig. 1). The many advantages of this type of structure like fast and versatile

Segmental bridge construction A bridge is a structure built to across a obstacles such as a body of water, valley, or road, for the purpose of providing passage over the obstacle. Designs of bridges depending on the function of the bridge, length of the bridge, span of the bridge, the nature of the terrain, and the material used to make it. This method uses the standard precast segmental erection methods with their high construction speed, but divides the segments into

- PRECAST SEGMENTAL BRIDGE CONSTRUCTION

- Construction of the Precast Segmental Approach Structures for Sutong Bridge

- Precast Segmental Bridge Construction Part 1

- Segmental Bridge Construction Process

- Precast Segmental Bridge Construction Part 4 Balanced

This document summarizes a seminar on segmental bridge construction. It defines what a bridge is and its typical components. It then discusses various construction methods for bridges, focusing on segmental bridge construction. Segmental bridges are built by constructing short precast concrete segments and then erecting them to form the full bridge. The document outlines the Span-by-span construction with self-launching gantries is the most common, and often the most cost-effective, construction method for precast segmental bridges. Segmental Bridges are varied in types such as: incrementally launched, long line castings, cable stayed, precast segmental progressive placement, arches, cast-in-place segmental, short line match cast precast segmental construction, etc. This course will consider Precast Segmental substructures and superstructures utilizing short line match casting of precast elements and

A follow on course to Precast Segmental Bridge Construction — An Introduction providing more detailed information on the Span-by-Span method of erection. Topics covered in the course include: Erection Equipment, Lifting and Transporting Segments, Truss Placement, Erection Geometry, Span Erection, and Stressing and Grouting. Segmental concrete bridges can be constructed by either assembling precast concrete segments or casting the segments in place. The balanced cantilever technique can be used in both precast and cast-in-place concrete construction to minimize the unbalanced moments induced in the towers or pylons. Alternatively, in cases where environmental conditions or construction

SECTION 452 PRECAST SEGMENTAL BRIDGE CONSTRUCTION 452-1 Description. Fabricate, store, transport and erect precast structural concrete superstructure and/or substructure segments on a prepared foundation, to the established lines and grades, in accordance with the design, dimensions and details shown on the plans and in accordance with this Introduction The popularity of precast concrete segmental bridge construction has grown worldwide in the last few decades. These types of bridges offer many benefits to owners like reduced costs, reduced construction time, reduced environmental impacts, and reduced maintenance of traffic. These benefits can be achieved while utilizing local labor and materials, Segmental Bridges are varied in types such as: incrementally launched, long line castings, cable stayed, precast segmental progressive placement, arches, cast-in-place segmental, short line match cast precast segmental construction, etc. This course will consider Precast Segmental substructures and superstructures utilizing short line match casting of precast elements and

Precast Concrete Segmental Bridges offer many benefits to owners like reduced costs, reduced construction time, reduced environmental impacts, and reduced maintenance of traffic. These benefits can be achieved while utilizing local labor and materials, better means of quality control, and with minimum requirements for future maintenance. They also offer additional structural cdn.ymaws.com The precast segmental approach structure of the Sutong Bridge was a pilot project of this type of balanced cantilever construction in China. It was the result of the leadership and entrepreneur spirit of Jiangsu Provincial Sutong Bridge Commanding Department (STB).

The following Chapter 4 presents the important techniques for erection of concrete segmental bridges. Their characteristics are outlined so that understanding of the specific nature of each of these methods can be achieved. Apart from that this chapter deals with the most important issue of construction loads by distinguishing the various types of construction loads and showing The most used prefabricated concrete elements for bridge construction are prestressed I beam, prestressed box beam, prestressed channel, and slab span. Prestressed concrete (PSC) box girders are considered one of the most flexible forms of the bridge deck. For spans above 50 meters, PSC Segmental Box Girder Bridges are the economical choice. The webinar discusses PSC Box Girders and PSC Segmental Bridges.

32 With the introduction of the soon to be ratified AASHTO-PC/-ASBI Segmental Box Girder Standards, precast, prestressed concrete producers have the opportunity to more fully participate in the segmental bridge market, which is estimated to have an annual construction volume of about one billion dollars in North America.

- Praktikum Presse – Praktikum Presse Öffentlichkeitsarbeit

- Praxis Für Nuklearmedizin Dr. Med. Tatiana Kandror, Mainz

- Preisliste 2024* Für Vollstationäre Pflege

- Prejudice In Urdu : Pride and Prejudice Summary in Urdu Translation

- Preenchimento Gengival: Entenda Como Funciona Essa Técnica!

- Praxis Anne Beate Berghäuser – Frau Anne Beate Berghäuser ist nicht auf Doctolib

- Preiser 29116 Eisverkäufer : Preiser Eisverkäufer 29116

- Premier Prix Du Conservatoire , il obtient le premier prix du Conservatoire

- Praxis Für Ergotherapie In Eschborn Nähe Frankfurt Am Main

- Pre-Paid Mobile Sim Cards In Airport?

- Praktikum Sonax Gmbh : Founder’s Associate Praktikum in Frankfurt bei Promodoro GmbH

- Preisentwicklung In Deutschland: Inflationsrate Sinkt Auf 7 Prozent

- Praxisgemeinschaft Dres. Rudolf Riedl Und Michael Zellner Bad Füssing

- Pre-Loved Watches Range , Sell Your Used Luxury Watches

- Praktikumsplätze China In Wasbek