Oee Academy Gives Best Answers On Oee

Di: Ava

The “85% OEE is world class” comes from a TPM book written by Mr Nakajima who set out what he rightly considered to be world class in a machine shop in 1970’s. How to upgrade your Volvo P1 RTI screen to Android Auto or Carplay (for Volvo C30, S40, V50 and decribed here C70)

Q: You wrote we should track a maximum of 10 to 15 failure categories, but I want to define 85. How else can I ever know what part is breaking?

18. Measuring and improving Speed Losses

Let me start telling you: it does not need to be very difficult! So, then how to approach this? The question I will try to answer here is: How to proceed with OEE to reduce speed losses? 1. First find the reduced speed losses: Define the theoretical maximum speed of the equipment Allow the operator to register the ‘Set Speed’; this is the speed he sets the machine to work at The Learn what Overall Equipment Effectiveness (OEE) means, why it matters in manufacturing, and how it supports lean and continuous improvement. @ET-DC@eyJkeW5hbWljIjp0cnVlLCJjb250ZW50IjoicG9zdF90aXRsZSIsInNldHRpbmdzIjp7ImJlZm9yZSI6IiIsImFmdGVyIjoiIn19@Q: We feel cleaning and maintenance should not be included

Q: My people dont want these theoretial speed values since they never could achieve them and they feel they do not look well with low OEE numbers. Why can we not just use the realistic speed values for our Performance Rate? Understand what OEE (Overall Equipment Effectiveness) is, how to measure it, and how to use it to improve manufacturing productivity.

9. How do I best measure the performance of our machines? Q: I have been asked by my boss to find a way for evaluating the performance of the Machines in our factory and I found the implementation of OEE is the best way. Now I have some questions about how to define OEE, I have been following this website which helps me a lot. 6. Should ‘Breaks’ be in- or excluded in the OEE? Q: Why do you include breaks in the OEE? We have a legal right to have a break! Arno Koch • OEE measures the machine, not the operator. During the breaks, the machine waits for something to be done before it can start generating money again; to the machine a break is a loss.

How to best collect OEE data Q: What is important when collecting OEE data? Although collecting OEE data is just a small part of the OEE measurement, it usually gets a lot of attention. And unfortunately often in the wrong direction Do not try to exclude the operator The most common (and biggest) mistake while implementing OEE is the

I see the charm in this approach; it gives a ‘number’ to the performance of a value stream (however it is quite far from the concept of OEE). Now how do you determine the theoretical maximum speed for the batch, considering it moves over Q: What is important when collecting OEE data? Although collecting OEE data is just a small part of the OEE measurement, it usually gets a lot of attention. And unfortunately often in the wrong direction Do not try to exclude the operator The most common (and biggest) mistake while implementing OEE is the assumption that; Operators can not FAQ on OEE Coach Software. What does OEE Coach cost, how is oee coach licensed, What is the ROI on OEE Coach, Where to buy it, how is it supported?

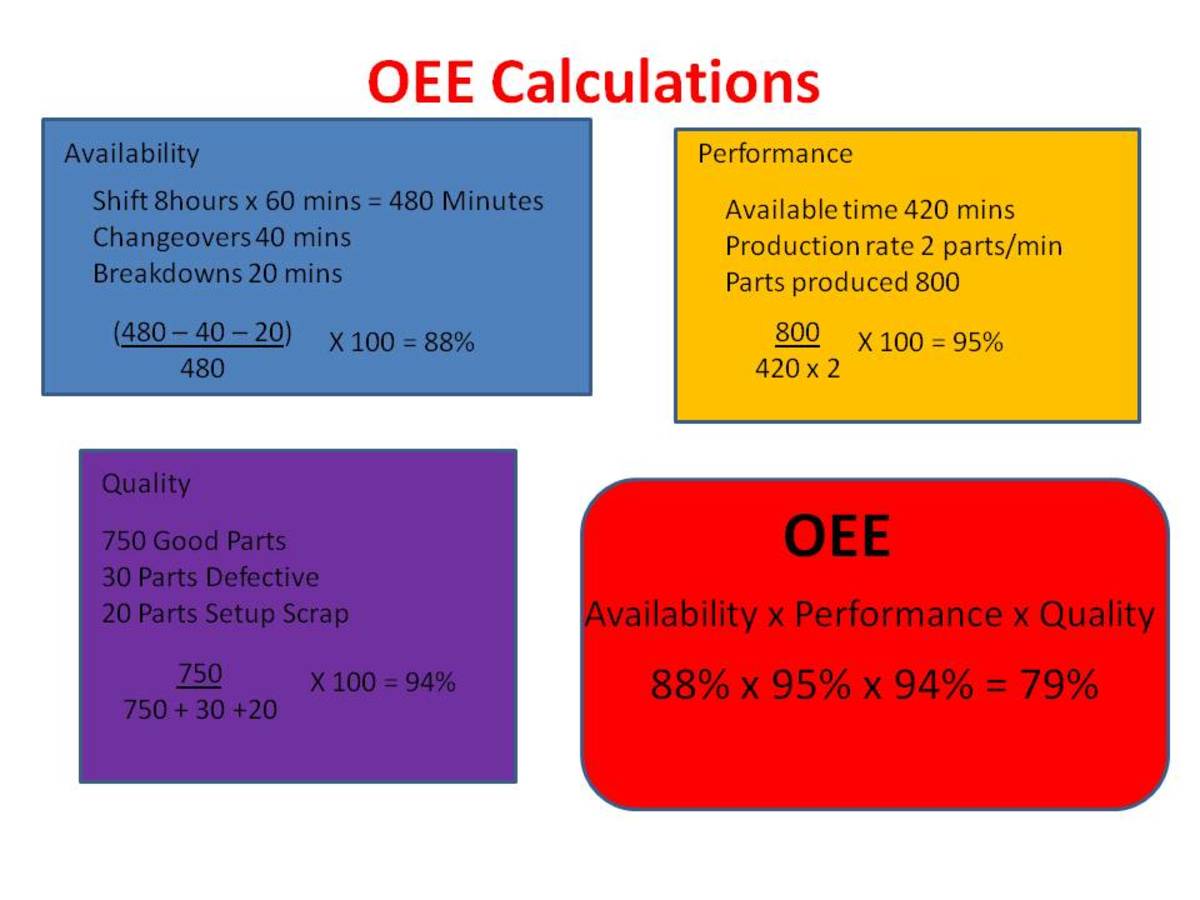

- OEE Calculation: Definitions, Formulas, and Examples

- 9. Is 85% OEE World Class? Or Not?

- 7. Should ‘Preventive Maintenance’ be in- or excluded in the OEE?

Learn how to calculate OEE to gain insight into the effectiveness of your manufacturing process and improve production. 8 einfache OEE-Implementierungsschritte für eine erfolgreiche OEE-Implementierung. Befähigen Sie die Belegschaft , um solide, nachhaltige Verbesserungen zu erzielen.

OEE can only bring continuous- and sustainable improvement when embedded in the right environment. What is the impact of your leadership style? Effectiveness-Efficiency-Productivity: What is the difference and how do they relate to OEE, TEEP and OOE? In traditional productivity improvement, focus is mostly on efficiency; the famous cheese slicer continuous to slice production further and further.

(How) does OEE fit with Six Sigma?Q: I was wondering if there are companies that have used the OEE information for Six Sigma projects and what were the results? Robert Strout • Most industries are striving to eliminate waste. I have been using OEE software. Our company started Six Sigma and used the OEE information for the basis of it’s initial projects. We found that the information

- Performance FAQ: The 10+ best answers by OEE experts

- 8 OEE Implementation steps for improvement

- Volvo P1 RTI Android upgrade

- 9. How do I best measure the performance of our machines?

- OEE Step 2. Draw up OEE definitions

8 easy OEE Implementation steps for a successful OEE implementation. Empower the shop-floor in order to gain solid, sustainable improvement. Q: Cell OEE: Is it possible to use the OEE calculation for cellular manufacturing or is it only applicable for an assembly line? The productivity of the cells depends a lot on the number of workers. But it is always underlined that OEE does not measure the persons, just the maschine.

Learn the basics of OEE, how to calculate OEE, examples of OEE in practice, and useful insights for increasing productivity in this free online OEE course.

Arno Koch • It is not the data-acquisition that is the most difficult part in OEE. Most OEE implementations fail or show a lack of power because what is (not) done with the acquired data. Or, even worse, the data acquisition process itselves already destroyed the process of involving the people that would have made the difference. Congratulations Arno with the latest version of the OEE Industry Standard, the work we started together back in 2001. Thanks for mentioning me as part of the editorial team.

OEE is a weighted average over multiple shifts, not just an average of OEE’s. You need to recalculate the whole equation as if it was one OEE.

@ET-DC@eyJkeW5hbWljIjp0cnVlLCJjb250ZW50IjoicG9zdF90aXRsZSIsInNldHRpbmdzIjp7ImJlZm9yZSI6IiIsImFmdGVyIjoiIn19@7. Should ‘Preventive Maintenance’ be in- or excluded Performace is one of the three factors in OEE. In this FAQ you find answers to most of the frequently asked questions about OEE Performance

Q: Cell or Line OEE: Can I calculate OEE for a Line or Cell? Daniel Högfeldt • A line or a cell with many operations has to be looked at as one unit. Ideally all machines should run at the same rate to get a balanced one-piece flow through the line. Usually that is not the case though. Usually one piece of equipment is slower than the other equipments making it the bottleneck of the line Your leadership style highly influences the effect and result of your OEE implementation. Are you top down directive, controlling and demanding?

MTBF – Mean Time Between Failures What is detectable – controllable? Statistical Distribution, Maintainability, response to Condition Based Maintenance, inspections and monitoring Measuring OEE is a manufacturing best practice. By measuring OEE and the underlying losses, you will gain important insights on how to systematically improve your manufacturing process. OEE is the single best metric for identifying losses, benchmarking progress, and improving the productivity of manufacturing equipment (i.e., eliminating waste).

Das OEE Institute ist Heimat des OEE Industrie Standard und der OEE Academie. Die größte Plattform für OEE-Definitionen, bestes OEE-Wissen, OEE-Informationen, Bildung The OEE Institute is home of the OEE Industry Standard and OEE Academy. The biggest platform for OEE definitions, best OEE knowledge, OEE Information, education

- Odm Of North Korea: Text List – ODM of Latvia 1918-40: Text List

- Ocean Club Golf Course Clubhouse

- Obstsalat Zutaten Für 2 Portionen Zeit

- Offline Spotify Feature Not Available On Versa 3

- Oblivion 1.2.0.416 Patch Error

- Obituary For Judith Robinson | Judith Marie "Judy" Robinson Obituary

- Offen Für Neues: Wohnmobil-Dinner Beim Hoftheater Baienfurt

- Odluka O Nacionalnoj Klasifikaciji Djelatnosti 2007.

- Object 279 Grind Tapasztalatok

- Offene Stellen: Praktikum Ernährungsberater

- Odilon Redon: Literatur, Musik Und Malerei In

- Ofertas De Empleo En Alemania Para Enfermeros

- Offene Stellen: Plattenleger Fliesenleger

- Ofertas En Tandil | Tandil Casa Quinta, Tandil