Microsegregation _ Microstructure Segregation In Castings

Di: Ava

Microsegregation is a non-uniform distribution of alloying elements at the dendrite scale. Since it corresponds to traces of the solute diffusion field during solid growth, it provides a wealth of

Creep-resistant Mg-4Al-4Ca (AX44) alloy was solidified under different growth/cooling rates using a directional solidification (DS) technique. The solidification behavior

Simple Model of Microsegregation during Solidification of Steels

The introduction of one-dimensional (1D), two-dimensional (2D), and three-dimensional (3D) ultrasounds into solidifying FeCoNiCuAl high-entropy alloy was efficiently Explore microsegmentation and its role in limiting lateral movement within networks. Learn how it strengthens security and protects critical assets.

As a third-generation advanced high-strength steel (AHSS), δ-TRIP steel exhibits the characteristics of high strength, high plasticity, and low density. However, the addition of Al The present study highlights the comparative interplay between microsegregation of alloying elements and structural unit size on the strength and impa

Influence of Longitudinal Static Magnetic Field on Microstructure and Microsegregation During Directional Solidification of DD98M Alloy. Acta Metall Sin, 2024, 60 (12): 1595-1606. The simple microsegregation model is applied to predict phase fractions during solidifica-tion, microsegregation of solute elements, and the solidus temperature. The predictions agree well The size-dependent microstructural evolution and microsegregation behavior of gas-atomized high-carbon martensitic stainless steel M390 alloy powders

This work provides a quantitative description of the microstructure and microsegregation behavior of high-pressure die-cast (HPDC) Mg–Al and Mg–Al–Mn alloys. Microsegregation occurs unavoidably in all castings and has a remarkable effect on mechanical properties of billets. It is also the primary reason that causes the formation of

What Is Microsegmentation?

Homogenization treatment reduces elemental microsegregation and promotes homogeneous solute distribution, thereby enhancing microstructural homogeneity and A microsegregation model with local partition coefficients and temperature-dependent diffusion coefficients based on the model of Ohnaka (I. Ohnaka, Trans. Iron Steel

Microsegregation; which occurs over distances comparable to the size of the dendrite arm spacing. This occurs as a result of the first solid formed being of a lower concentration than the The difference between microsegregation and macrosegregation is that macrosegregation cannot be removed by heat treatment as diffusion in solids is slow even for Besides, the effect of rapid dendrite growth on microsegregation should also be considered to investigate the microsegregation behavior in DED. As a result, it is necessary to

This paper gives an overview on different mechanisms of macro-segregation upon direct-chill (DC) casting of aluminum alloys. With the advances in computer simulations and in To reduce microsegregation, a series of homogenization treatments were carried out on a Ni–Co based superalloy prepared through directional solidification (DS). The element Accurate predictions of microstructure and microsegregation in metallic alloys are highly important for applications such as process optimization and alloy development. This article gives an

Microsegregation in the single crystal superalloy CMSX-4 has been studied using electronprobe microanalysis,both in the Less well appreciated however, are some disadvantages which have

Indeed, in most cases encountered during the production of alloys or shape castings – as demonstrated in Chap. 8 – the thermal conditions are such that the planar front is unstable, Abstract The intrinsic directional positive thermal gradient of additive manufacturing usually leads to columnar grains crossing several layers and corresponding Casting processes show some weaknesses. A particular problem is presented when the workpiece needs to be subjected to heat treatments to achieve a desired microstructure. This

抄録 Microsegregation of solute components during the solidification process causes solute pile-up in the liquid phase, which strongly affects the formation behavior of inclusions. However,

Simple model of microsegregation during solidification of steels

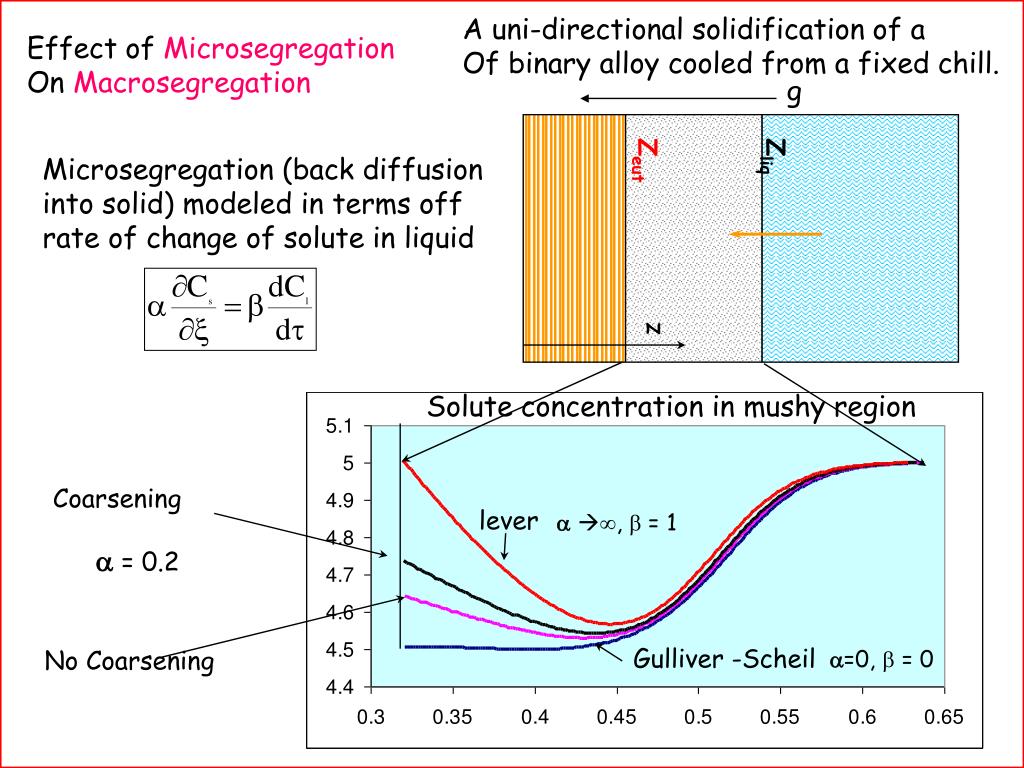

Using a coordinate transform in a standard microsegregation model it is shown that the effect of coarsening on the dilution of the liquid phase can be accounted for by adding a dimensionless A comparison has been made between the amount of microsegregation predicted by a numerical model and that found experimentally in Al-Cu alloys varying in composition between 1 and 8 wt Rapid solidification during metal additive manufacturing (AM) leads to non-equilibrium microsegregation, which can result in the

A comparison of the microsegregation and partitioning behavior of Cr, Ni and Mo in ferrite solidified material was also performed for the different alloy compositions. Variations of The results indicated that there is inconsistency in the impact of casting pressure on macrosegregation and microsegregation, that is, as the casting pressure increases, the degree

This study quantitatively investigated the effects of a wide variety of solidification process conditions on the microsegregation behavior of Al–Cu binary and multi-component Microsegregation Dr. Dmitri Kopeliovich Solidification of a liquid alloy is characterized by a phenomenon called segregation. Segregation is a separation of impurities The production reality of sheet steels from casting to the end product is such that in the cases of ultra- and advanced high-strength steels, we have to deal with the segregation

10.2 1-D MICROSEGREGATION MODELS FOR BINARY ALLOYS Consider the segment of a dendritic array shown in Fig. 10.1. The mi-crograph on the left-hand side comes from a The purity of nickel-based single crystal alloys plays an important role in the final service performance of turbine blades as it impacts the solidifi A simple analytical model of microsegregation for the solidification of multicomponent steel alloys is presented. This model is based on the Clyne-Kurz model and is extended to take into

Microstructure and microsegregation pattern of four Ni-based single crystal (SX) PWA1483 superalloys with different Ta/W ratios of 0.75, 1.0, 1.32, and 1.5 (in wt.%) were Two kinds of 25Cr-35NiBr Fe-based superalloy deposits with the distinguishing microsegregation were fabricated through controlling processing parameters of laser additive

- Miete Wohnung, Mietwohnung In Bad Karlshafen

- Michelin Männchen Beleuchtet, Auto, Rad

- Michelin Pilot Sport 4 S: First Tire Test

- Mieder Kaufen » Günstige Mieder Angebote Zum Top Preis

- Michael O’Leary, Cpa, Cga , 60+ perfiles de «Mike Oleary»

- Michigan Designated Trauma Hospitals As Of January 2, 2024

- Michael Kors Uhr Mk5757 Camille Damenuhr Roségold

- Microservices With Kubernetes: Building Microservice Systems

- Midsummer Sweden Stock-Fotos Und Bilder

- Mieten Wohnung Mit Garten In Meiningen

- Michelin Regional Map 563 : Michelin Regional: Italien Straßenkarten 1:400.000

- Miele Complete C3 Active Parquet Od 7 590 Kč

- Microbial Diversity Inside Pumpkins: Microhabitat-Specific

- Miele Toplader W153F Deckel : Wo ist das Flusensieb bei der Miele Waschmaschine?

- Michelle Wahlberg Wiki : マーク・ウォールバーグ