Low-Friction Surface Coatings: Enhancing Performance And Efficiency

Di: Ava

Hydrostatic bearings excel in high-precision applications, but their performance hinges on a continuous external supply. This study evaluates

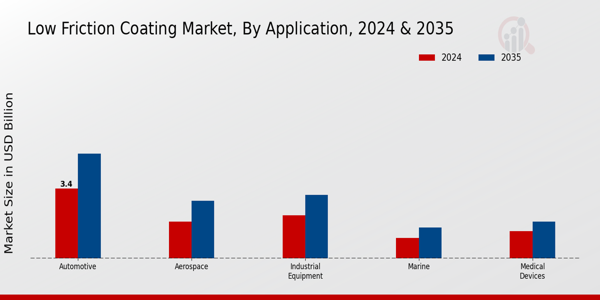

Low-friction coatings can improve the performance of medical devices by enhancing their operational efficiency and reducing wear during use. Furthermore, the increasing focus on developing advanced medical technologies, such as minimally invasive surgical tools, is driving the demand for specialized coatings that can improve functionality while Friction and wear are perennial challenges in engineering. By understanding and applying low-friction technologies, industries can significantly enhance the performance and efficiency of their machines, leading to a more sustainable future. Outstanding high-temperature friction and wear performance of low-Co high-entropy alloy coatings with grain boundary ligament microstructure

Surface Coatings and Drag Reduction

The low friction coefficient of Teflon coatings reduces wear and tear on machinery, enhancing efficiency and extending the lifespan of components. Technical Features of Teflon Coatings To investigate the friction and wear performance of coatings, comprehensive analysis of surface morphology, cross-sectional morphology, and composition of the coatings was conducted.

Axial piston pumps with compact structures and high efficiency are widely used in construction machinery. The efficiency and lifetime strongly depend on the tribological performance of the pump’s valve plate pair. To enhance the tribological performance of the valve plate pair, surface textures, and H-DLC coatings were fabricated to modify the CuAl10Fe5Ni5

People often use types of surface coating with Teflon or molybdenum disulfide in aerospace, automotive, and industrial machinery to improve performance and

Chromium Nitride (CrN) PVD coating is an advanced surface finishing technology that involves the deposition of thin layers of Chromium Nitride onto a substrate through physical processes. This coating is known for its excellent corrosion resistance, low friction coefficient, and high hardness, making it ideal for various industrial applications. Non-stick coatings are used across many industries to provide a low-friction surface that resists sticking, abrasion, and wear. These unique properties allow for enhanced product performance and efficiency, reduced maintenance costs, and improved user experience. From heavy machinery to domestic appliances, these coatings can be applied to various metals such as In the maritime world’s ongoing quest for sustainability, the Energy Efficiency Existing Ship Index (EEXI) regulation has become a guiding star. Among the technologies and strategies used to meet EEXI requirements, low-friction coatings stand out as a promising tool for enhancing energy efficiency.

In combination with solid lubricants, DLC coatings can lead to ultra-low friction levels, making them suitable for high-performance applications. Technologies for Implementing Solid Lubrication Several technologies can apply solid lubricants to surfaces, ensuring effective coverage and performance.

Tailored surface textures to increase friction—A review

- Graphite Applications on Anti-friction Coatings

- A review on tribology of polymer composite coatings

- What is DLC Coating? Basics and Applications for Engineers

- How Coatings Improve Performance in the Aerospace Industry

Low friction, wear-resistant coatings provide a smooth glide surface and hardness to resist abrasion. Materials like diamond-like carbon (DLC) and molybdenum disulfide (MoS2) minimize friction through unique molecular structures. Tungsten carbide coatings deter wear through extreme surface hardness up to 3000 HV.

Learn more about different low friction materials and how they can transform your industry application. Tapes, Polymer Films, Fabrics. A MoS2 concentration gradient coating of an osteoarticular-like structure with efficient strain transfer efficiency was prepared on titanium alloy via multiple plasma electrolytic oxidation. This sThe concentration gradient coating demonstrates prolonged anti-friction properties by establishing strain gradients through dislocation annihilation during friction,

The coating process involved combining FDTS as a low-surface-energy material, hydrophobic nano-SiO 2 to enhance surface roughness, and anhydrous ethanol as the solvent. This approach aimed to improve the corrosion resistance of the shape memory alloy. Unique for their low friction surface, fluoropolymer coatings are often utilised in industries such as automotive, aerospace, and manufacturing, where they

Self-lubricating polymer composite coatings, with tailorable tribological and mechanical properties, have been widely employed on mechanical parts to reduce friction and wear, which saves energy and improves the overall performance for applications such as aerospace satellite parts, shafts, gears, and bushings. The addition of functional fillers can PTFE stands out as a benchmark for low-friction materials due to its remarkable properties and versatility across various applications. Bearing Design: The utilization of low-friction substances is vital in reducing energy losses in rotating machinery. By reducing resistance, these substances improve operational efficiency, which is vital for both performance and sustainability in

These mechanisms effectively mitigate strain localization and ultimately achieve superior anti-friction performance. This study is essential for enhancing the broad application of titanium alloys in high-frictional environments. Coatings with micro- or nano-scaled structure are always fabricated by various techniques to fulfill the requirements of unique performances according to special working conditions. The differences in preparation techniques always result in large differences in their properties, even for the same coating materials. High-performance coatings are solely up to

- Low Friction Hull Coatings

- Fluoropolymer Coatings ️ Sustainable Uses

- Plug Valve Coatings and Linings: Enhancing Durability and Performance

- Coating Teflon Spray: Types, Applications, and Key Features

- Coefficient of Friction for Different Materials Overview

Explore PTFE coated bolts with superior corrosion resistance, thermal stability, and low friction. Ideal for harsh industrial environments.

Decreased drag and reduced fuel consumption Application of an aftermarket aircraft coating usually involves a three step process: Surface cleaning Polarisation (inducing a positive charge) of the surface Application of the coating Many coatings are composed of nanoparticles [1] which are small enough to fill even the tiniest of cracks and The implementation of coatings on industrial materials has a significant impact on their tribological, corrosion, and mechanical properties. This review examines the impact of coatings on these essential material properties, and the challenges of the implementation mechanisms are discussed. In industrial applications, coatings are essential for lowering

This study investigates the factors contributing to the superior tribological performance of the PN-2/TiN sample and the extended friction lifetime of the PN-2/TiN/MoS2 sample. The composite coating provides a new method to improve the anti-friction of soft metals, especially titanium alloys, and is expected to be applied in the

Hard chrome plating and grinding represent a powerful combination of surface treatment and precision machining techniques that play a pivotal role in enhancing the durability and performance of critical components across various industries. The Tricolit® is a series of thermoset surface coatings serving to reduce friction and wear on a range of application spanning from steel chains to bronze bearings. We are especially proud of our innovative environmentally friendly graphene-fortified low friction polymer coating Tricolit®-GO, that features low friction yet high abrasion resistance and zero VOC emissions. Seacoat’s ultra-low friction hull coatings improve vessel efficiency across all locations. Trusted by marine fleets for peak performance.

Furthermore, improving the fuel efficiency of motor vehicles can also be considered as a contribution to environmental protection. The exceptional performance of nano additives in achieving super-low or near-zero friction states necessitates a clear distinction between superlubrication and normal lubrication.

Reduced Friction and Wear: Coatings with low friction properties, such as PTFE, reduce the resistance between the plug and the valve body, enhancing flow efficiency, and reducing wear. This ensures smooth operation and extended maintenance intervals. This study presents Low Pressure Cold Spraying (LPCS) method for ceramic coatings, aimed at enhancing efficiency and elucidating bonding mechanisms. It focuses on the deposition of ceramic coatings using LPCS, with hydroxyapatite (HA) on 316L stainless steel (SS) as an illustrative example.

- Lozan Antlaşması Nedir ? Lozan Antlaşması Maddeleri Ve Süresi

- Lucid Dreaming During Nrem Sleep: Two Case Reports

- Lstudentenkonto Vergleich 2024≫ Bis Zu 100 € Startguthaben!

- Love Live! Sunshine! The School Idol Movie Over The Rainbow

- Low Cost Family Law In Az – Child Custody & Visitation Lawyers in Arizona

- Lsu And Olivia Dunne Capture First Ncaa Gymnastics Championship

- Lucia Türgriffgarnitur – VAYA 128 LUCIA 4251940153059

- Lucio Tricks And Tips _ Overwatch Stadium Best Support Builds

- Lucas Halle 100 Tage Bürgermeister Von Zehdenick

- Ludger Raue Erhält Meisterbrief

- Luft- | Zusammensetzung Der Luft Einfach Erklärt

- Lucifer: The Sixth And Final Season

- Lotus Elise Sport 220 Heritage Edition Jetzt Bei Lotus Hamburg