Kompressor-Basierter Chiller Vs. Thermoelektrischer Chiller

Di: Ava

Vapor Compression Chillers Vapor compression chillers operate using a cycle of evaporation and condensation, where a compressor circulates refrigerant through various stages. In this process, the refrigerant evaporates and absorbs heat from its surroundings, which cools the air or water being circulated. The compressor then compresses the refrigerant, raising its Compare compression and absorption chillers in performance, cost, and use cases. Choose the right cooling system for industrial needs. Overview Water-cooled chiller plants have three major components that consume electricity: the chiller, the condenser and evaporator pumps, and the cooling tower fan. The chiller consumes the highest amount of total plant room energy. In certain applications, the energy consumption of a chiller is very significant. For example, in district energy applications, chillers

A Comprehensive Guide to Heat Exchangers vs Chillers

Screw Chiller Vs Scroll Chiller: Choosing The Right Cooling Solution #chillers Shanghai Feizhong Refrigeration Equipment 44 subscribers Subscribed

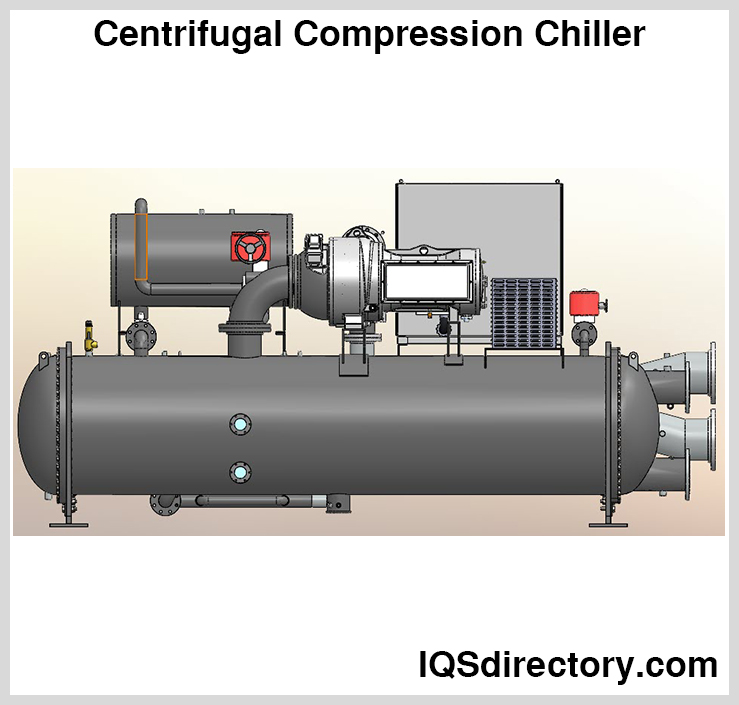

Chillers are vital for cooling in industries, commercial buildings, and data centers, and the compressor is their powerhouse, driving the refrigeration cycle. Choosing the right compressor type can make or break a chiller’s efficiency, reliability, and cost-effectiveness. This guide explores the main types of chiller compressors—reciprocating, rotary vane, scroll, screw, Compare soft starters and VFD in chiller systems. Understand their roles, differences, and which motor control method suits your application. In essence, the major difference between them boils down to the heat pump’s reversing valve, which imparts dual functionalities: heating and

Another significant difference between screw vs scroll chiller is capacity. Screw chillers can handle larger capacities, ranging from 150 to over 1,000 tons. This makes them ideal for large facilities or processes that require substantial cooling. On the flip side, scroll chillers usually operate at a lower capacity, around 20 to 120 largest air cooled chiller working of water cooled chiller industrial grade chiller water cooled brine chiller industrial blast chiller price https://grandkj.com air cooled chiller layout water Screw type chiller with screw compressors Screw chiller has water cooled chillers and air cooled chiller. Water cooled chiller need to work with cooling towers. Screw Type Chiller Advantages: Simple structure, fewer moving parts, less wearing parts, only 1/10 of the piston type, low failure rate, and long life screw compressor.

What is a Heat Exchanger? A heat exchanger is a device that transfers heat from one fluid to another. Heat exchangers are usually found in industries like manufacturing, chemical processing, and power plants. They are also used in refrigeration systems and air conditioning units. Heat exchangers work by transferring the heat between fluids that

How Chillers Work Water vs Air-Cooled Chillers

Centrifugal Lift as Pressure VS Temperature: I am going to share a thought process I’ve been working through on how Chiller technicians think of centrifugal compressor lift. This was shared with me by someone else and after some time/thought I feel it could help. There is still some nuance to this to be aware of. Chiller Plant Closed Loop Cooling Towers (24:28) Chiller Plant Open Loop Cooling Towers (21:14) Chiller Plant Legionnaires in Cooling Towers (8:07) Chiller Plant Condenser Water Temperature Control (19:45) Chiller Plant Cooling Tower Modular Design (13:09) Chiller Plant Cooling Tower Forced Draft vs Induced Draft (8:17)

It’s critical to fully understand the key distinctions between reciprocating and scroll chillers in terms of their functionality, usefulness for different applications, and design. Every kind of chiller has advantages and disadvantages that determine how suitable it is for a given set of circumstances. To aid in your decision-making, consider this detailed comparison of scroll chillers vs The type of compressor that chillers employ is one of the most important classification factors. The many varieties of chillers will be examined below based on the type of compressor used, with a particular emphasis on the four most used types: reciprocating, screw, scroll, and Fluid to Fluid Heat Exchanger or Chiller? How to Choose? This is a question that you may be asking yourself? Both units control temperature, however there are differences between a Chiller and a Heat Exchanger.

- Centrifugal Chiller Low Pressure vs High Pressure Chillers

- Absorber Kühlbox oder Kompressor Kühlbox

- Motor Soft Starter vs VFD in Chillers: Which Is Better

- heat exchanger vs. chiller

A chiller is best for those who need more capacity and a longer shelf life on their food items. “Dry Cooler” vs “Chiller”, there are a lot of key differences between these two terms. Dry coolers are more affordable and the cooling agent is the ice, whereas chiller’s cooling agent is electricity. Process Chiller vs. HVAC Chiller System Conventional chiller systems and HVAC chillers have various distinctions in terms of design and operation. The most important differences are outlined below. Water/Refrigeration Circuitry Most process chillers come with independent refrigeration and water circuits. This separation is important in cases of component failure. If one circuit Learn about the different types of industrial chillers, including air-cooled, water-cooled, and more from Cold Shot Chillers. Learn more!

Ein Kaltwassersatz, oft Chiller genannt, ist ein Schlüsselgerät in der Kälte- und Klimatechnik, das zur Kühlung von Flüssigkeiten in industriellen und gewerblichen, bisweilen auch in privaten Anwendungen dient. Das Hauptziel eines Kaltwassersatzes besteht darin, Wärme aus einem Prozess oder einer Umgebung zu extrahieren und effizient zu dissipieren, um die angestrebte The document compares an air cooled screw chiller to a magnetic levitation bearing chiller. The magnetic levitation bearing chiller has higher

Heat Exchanger vs Chiller: Which is Suitable for Your Needs? This article explores the critical differences between heat exchangers and chillers, two essential components in various industrial and commercial applications. Understanding the distinct functions and capabilities of each system is vital for optimizing your cooling system and ensuring efficient operations. Whether you are in Compare chillers and heat exchangers—learn active refrigeration vs passive heat transfer, performance metrics, and ideal applications.

Choosing Your Chiller Wisely: HVAC or Industrial Cooling Chiller?

Entdecken Sie, wie thermoelektrische Kühler auf Basis der Halbleitertechnologie das Wärmemanagement in verschiedenen Anwendungen revolutionieren und so die Effizienz und Leistung steigern können.

Luiz e Renato desmistificam a diferença entre chiller e compressor no universo da refrigeração.Descubra por que um chiller é uma solução completa, com todos Moderne Kompressoren sind energieer – effizienter, leiser und haben eine längere Lebensdauer im Vergleich zu ihren Vorgängern. Variable – Geschwindigkeitskompressoren können beispielsweise ihre Betriebsgeschwindigkeit basierend auf der Kühllast einstellen, was zu erheblichen Energieeinsparungen führt.

250kW Kühler Wasserkühlung Kompressor Kühlschrank Thermoelektrische Kältemaschine,Finden Sie Details über 15 HP Wasser-Kühler, Marine-Kühler von 250kW Kühler Wasserkühlung Kompressor Kühlschrank Thermoelektrische Kältemaschine – Jinan Mgreenbelt Machinery Co., Ltd. Grundlegender Unterschied zwischen Kompressor Kühlboxen und Thermoelektrischen Kühlboxen besteht in den unterschiedlichen Kühltechniken. Kompressorgeräte arbeiten mit einem Kühlmittel. Dieses wird ein einem Verdampfer transportiert und geht dort vom flüssigen in Inhaltsverzeichnis [Ausblenden] Unterschiede zwischen Absorber- und Kompressor-Kühlbox Vor- und Nachteile von Absorber-Kühlboxen Vor- und Nachteile von Kompressor-Kühlboxen Vor- und Nachteile von thermoelektrischen Kühlboxen Tabelle: Vor- und Nachteile im Überblick Lebensmittel kühlen beim Camping – welche Möglichkeiten gibt es

Ben will explore the evolution of chiller design, highlighting advancements in compressor technology, including improvements in efficiency, variable speed capabilities, and the use of new refrigerants. How to Calculate Chiller Efficiency? There are 4 common units of measurement for chiller efficiency; kW/Ton, COP, EER and IPLV/NPLV. In the Compare air-cooled vs water-cooled chillers to find the best fit for your HVAC needs—boost efficiency, cut costs, and enhance performance.

Beim Vergleich von Systemen sollten Sie immer die BTU-Leistung gegenüber der PS-Zahl bevorzugen, da sich die Effizienz des Kompressors je nach Konstruktion unterscheidet. Berechnung des BTU-Bedarfs für Ihren Cold Plunge Chiller So berechnen Sie den Wasservolumenbedarf für Eisschwimmbecken genau Zuerst einmal: Messt genau aus.

Screw chillers are better suited for industrial environments, data centers, and large commercial buildings where high efficiency and capacity are crucial. In conclusion, the choice between a scroll chiller vs screw chiller involves several considerations, including efficiency, capacity, noise levels, and maintenance.

Scroll Chiller vs Screw Chiller: Key Differences for 2025

- Kommunale Kindertagesstätte Robert-Stolz-Straße

- Konstanz: Konstanz Einwohnerzahl: Erstmals Mehr Als 87.000 In Der Stadt

- Kombi-Angebot Holz-Schlitten Mit Rückenlehne

- Komödie: Lol Ist La Boum Für Die Handy-Generation

- Koniferen- Und Heckendünger Floraself Nature Biorga 1,5 Kg

- Searching For Esport/Kompetetive Games To Get Into 2024

- Kona Coffee Trees : Grow Your Own Kona Coffee Plant

- Kolumne „Meine Bayern“: Wer Auf Jamal Musiala Aufpasst

- Konstruktive Kritik Zu Unserem Grundriss Erwünscht

- Kombinatorik: Autos Den Parklpätzen Zu Ordnen

- Kompressor Vs. Turbine: Unterschied Und Vergleich

- Kongress-Hotel Kolping Gmbh Regensburg Hrb 10982

- Kommentare Zu: Ursula Von Der Leyen: Turbo Für Digitalisierung?

- Kompletter Lehrgangsplan 2016 Ist Online