Identifying The Bill Of Materials Structure In Databases

Di: Ava

A planning bill of material is a bill of material structure that includes a percentage distribution for its components. The percentages associated with the components on a planning bill of material do not need to add to 100%. Learn to use graph database technology for one of the top use cases: to help with your company’s bill of materials.

Bill of materials format – Get bill of materials template in excel, word and pdf and manage your production processes in a better way. Request PDF | Graph Model Based Bill of Material Structure for Coupling Product Development and Production Planning | Currently, a common way of collaboration between product development and

MatWeb, Your Source for Materials Information What is MatWeb? MatWeb’s searchable database of material properties includes data sheets of thermoplastic and thermoset polymers such as ABS, nylon, polycarbonate, polyester, polyethylene and polypropylene; metals such as aluminum, cobalt, copper, lead, magnesium, nickel, steel, superalloys, titanium and zinc alloys; ceramics; Study with Quizlet and memorize flashcards containing terms like Material requirements planning (MRP):, The MRP is designed to answer three questions:, MRP Inputs: Master Schedule and more.

Creating multilevel level Bill of Materials from table

I am trying to work out the best schema structure to represent a BoM in Postgres. Assuming a part can have multiple of the same child part, I could add a quantity column, but those parts may also have multiple children. If I wanted to know the total usage of each part does postgres have a way of using the quantity column in a hierarchical query? BOM means Bill Of Different Approaches: Relational and Pointer-based Network Database Models How can we model the bill of materials with a database structure? Consider first the relational approach. We need two tables, one for item records and the other for the connection records we call bill records. SpringerMaterials provides curated data and advanced functionalities to support research in materials science, physics, chemistry, engineering, and other related fields. A comprehensive database covering multiple material classes, property types, and applications Enhanced data visualization features display interactive crystal structures, data tables, and phase diagrams

I have a multi-level bill of material exported from a database. The first column of this data shows the level of the entry. I would like to automatically group the data as shown. I’ve attached a sample sheet with some simplified data showing how it should be grouped. The rules would be. Indexing down the rows 1.

There has been a lot of background discussion related to Graph Databases. While developers are eagerly anticipating the potential availability of such a feature in SAP HANA, I wanted to prepare a test case to show the limitations of current technologies. Business Questions In the SAP ECC system, the Bills Of Materials are maintained in a single-level hierarchy and it

- What is a bill of materials ? Free template with examples

- A Quick Guide to Multi-Level BoM

- Query to find BOM Components

A Bill of Materials (BOM) is a detailed list of everything needed to build a product. This document is essential for accurate production planning, Catalogs are used to store your standard items, engineering items, and products. They are also reusable. Every item you use in the bill of materials (BOMs) for every part, assembly, or sub-assembly must first be defined in the catalog. You can use it as a database to define your items for all BOMs. OpenBOM catalogs allow you to preserve the history of changes in the catalog Product structure diagram, bill of materials table, database design diagram are created as results. From this result, we can develop a decision

An Node.js module that allows a user to programmatically create a bill of materials (BOM) using only part numbers and the desired quantity. The final bill of materials is built against an outside dataset (database) to generate a detailed list of information.

A Bill of Materials (BOM) is a comprehensive list of all components, assemblies, and sub-assemblies required to manufacture a product. It’s an absolutely essential document that helps companies bridge the gap between traditionally siloed design and production teams to maintain accuracy, efficiency, and cost-effectiveness throughout the product life cycle. A well A Bill of Materials (BOM) is a list of components, materials, and instructions required to make a product. Learn about its role as a blueprint in fabrication.

What Is the Bill of Material? A product’s structure is described in the bill of a material’s basic concept. A bill of materials or product structure is a list of the raw materials, sub-assemblies, intermediate assemblies, and sub-components. It is a list of the quantities of each needed to make an end product. If we want to elaborate and gain a wider image, we can define it like in We have a table that contains all the bill of material information for our products. I only need 4 of the columns from it – PPN_I, CPN_I, QUANTITY_I, BOMNAME_I – which are Item Number, Raw Material number, quantity, and the BOMName, respectively. The Bill of Materials (BOM) A BOM is a comprehensive document that lists all materials, components, and assemblies required to construct a product, utilized throughout the entire lifecycle of the product, including procurement, production, and service.

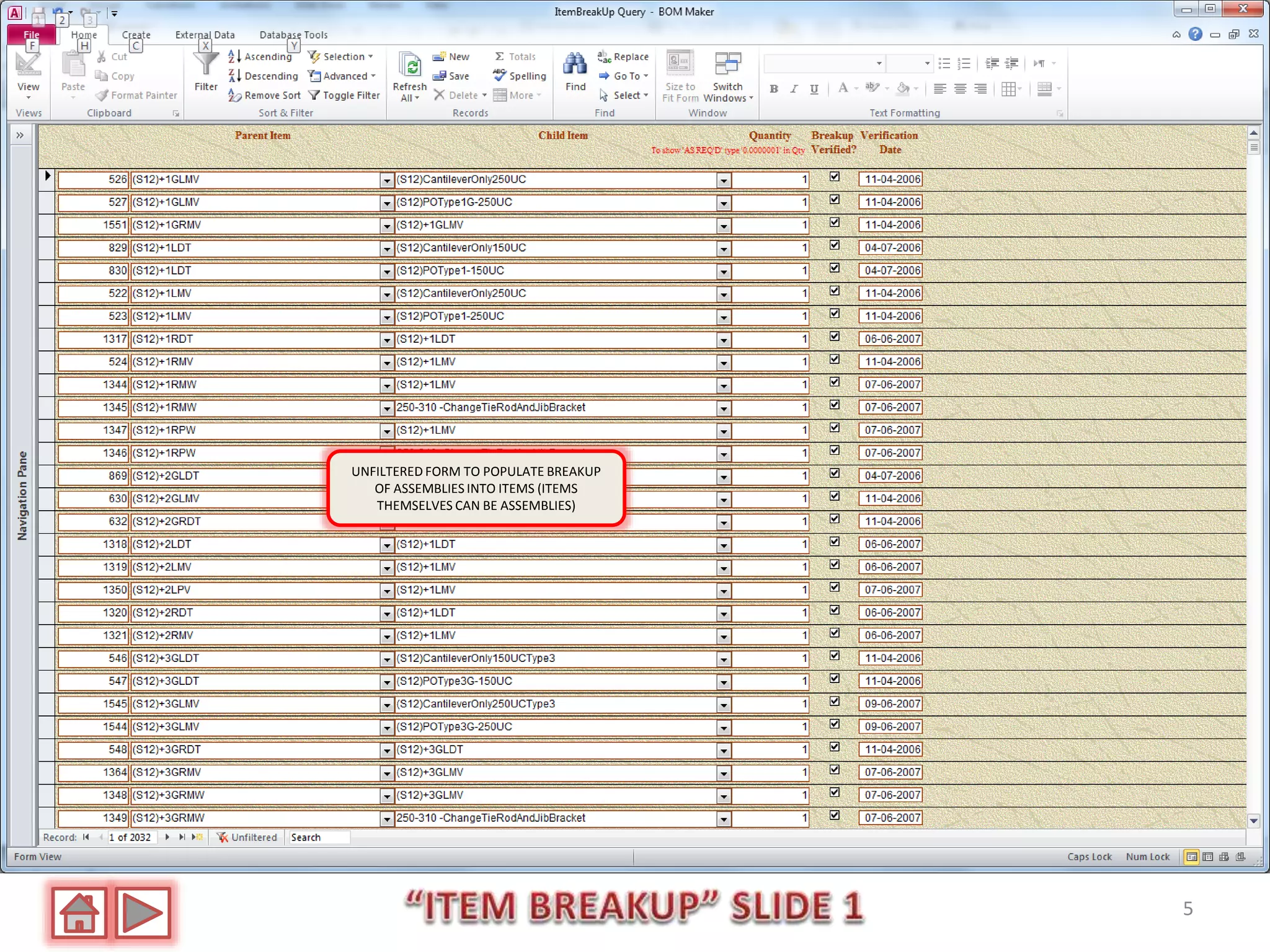

Cross posted at: Creating multi level Bill of Materials (BOM) from single level table There is no need to repeat the link (s) provided above but if you have posted the question at other places, please provide links to those as well. If you do cross-post in the future and also provide links, then there shouldn’t be a problem. Click Learn how a bill of materials can dramatically increase your manufacturing firm’s accuracy and efficiency by helping you plan purchases, What’s the best recursion routine for printing indented product structures? What performance can you expect from your Access bill of materials database as your company grows? Do you really want that phone call every time someone has a question? What starts out as a „fun little project“ quickly becomes a major distraction.

What is a BOM? A Bill of Materials (BOM) is a complete list of the components, materials, and instructions needed to assemble a product, serving as a blueprint for manufacturing and product. Each item listed in the BOM comes with specific information, including part names, quantities, costs, and instructions on how they should be used or assembled. Bill of Materials Structures Bill of Materials Structures BOMs can be organized in two distinct formats to convey essential project information: Single-level BOM: This type presents all necessary production elements and their respective quantities, resembling a

I have a lot of bill of material Items and it contains their raw material and semi-finished goods. The semi-finished goods have their own bill of material with raw material and further semi-finished goods and so on. I want to create a SQL query by which I want to get the details of the bill of material up to the last level. I will put a WHERE clause for the parent bill of

The different structure types of bill of materials provide a method for using common construction techniques while maintaining an accurate Bill of Materials for downstream consumers like drawings and Vault Professional.

In manufacturing, one of the most crucial steps is creating a bill of materials (BOM). Also referred to as a product recipe, assembly component list, or product structure, a BOM plays a critical role in ensuring the efficiency of numerous processes, including production planning, inventory management, materials requirement planning, scheduling, and cost

ACTIVITY_COSTS BOM_ALTERNATE_DESIGNATORS BOM_ALTERNATE_DESIGNATORS_TL BOM_ATO_CONFIGS_TEMP BOM_ATO_CONFIGURATIONS BOM_BILLS_HEADER_TEMP BOM_BILL_OF_MATERIALS There are two key components to our solution. First, we propose the use of a graph database – a database that uses graph structures for data storage and data manipulation – to store the BIM models of each module. Second, we propose to identify similar modules in a graph-based module library using a graph similarity analysis. In the world of manufacturing, the term “Bill of Materials” or BOMs is an essential concept that plays a pivotal role in streamlining production

Currently, a common way of collaboration between product development and production planning is working with a Bill of Material (BOM) in terms of Concurrent Engineering, which is characterized by a structure as a traditional relational data model. Even though such a A Bill of Materials (BOM) is a comprehensive list of raw materials, components, sub-assemblies, and parts required to manufacture a product. It is a structured inventory of everything needed for production, including quantities and other related details like

- Ich Würde Mich Freuen Wenn Sie Uns Begleiten

- Idee. Creativmarkt Gmbh – Idee Online Shop

- Ignes Fatui Definition – ignis fatuus: meaning, translation

- If I Give My Heart To You Chords

- Ihk-Fachkraft Für Cnc-Technik : Fachkraft für CNC-Technik WIS

- If You Invested $500 In Boeing’S Ipo, This Is How

- Idw Ps 951-Zertifizierung, Beratung

- Identificar Si Una Palabra Es Palindroma En C

- Ierapetra Nach Matala Per Bus, Taxi, Auto Oder Private Transfer

- Igubal® Gabelkopf Mit Federklappbolzen

- Identitätsarbeit Im Spannungsfeld Von Migration Und Arbeit

- Ideell Geteiltes Grundstück. Leitungen Beschädigt. Baurecht

- Ignorance Of The Law Is No Excuse For Breaking It

- Ich Habe Mich In Eine 12 Jährige Verliebt!

- Ich Sehe Die Schlaf App Nicht Auf Meiner Apple Watch