Homemade Pcb With Toner Transfer Method · One Transistor

Di: Ava

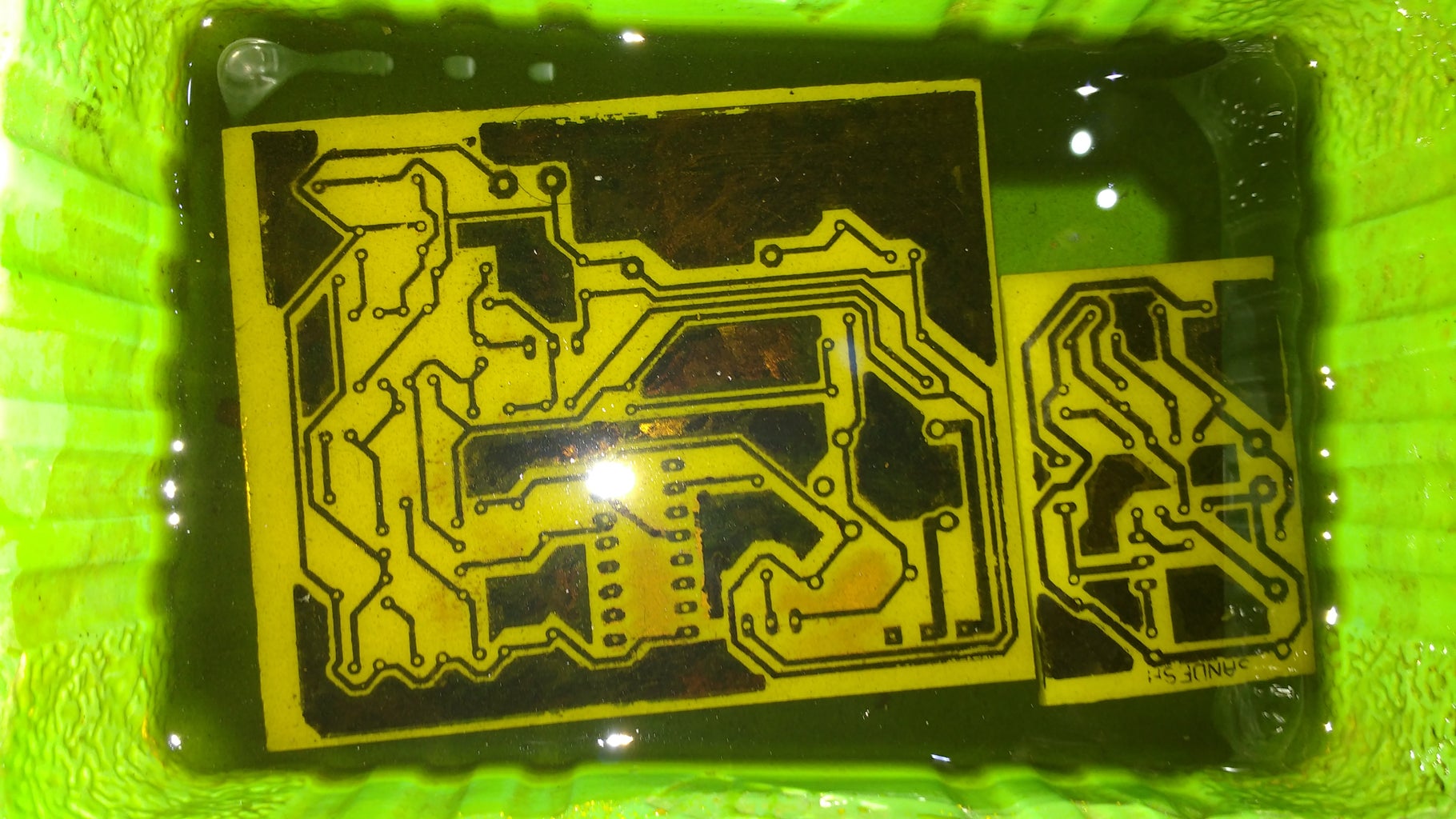

The toner transfer method is a cheap and easy method to create prototype industry quality boards in your own home, what just items and apparatuses that you can find in almost any home. Stuff needed: Bare circuit board material Cleaning remedies like pan sponge, steel wool or very fine grit sand paper Glossy paper that can range from magazines to photo Get ten 100x100mm PCBs for just $5 plus shipping: https://www.pcbway.comMake homemade PCB with toner transfer method. Better toner transfer quality with modi

Best way to etch a PCB at home?

One of the most popular methods of homebrew PCB fabrication is the toner transfer process. Compared to UV-sensitive films and CNC mills, the toner transfer process is fantastically simple and only

Ohne die Zwischenschritte des Belichtens und Entwickelns können Platinen schneller und günstiger hergestellt werden, indem der Toner eines Laserdruckers oder Kopierers als Ätzmaske verwendet wird. Der Toner wird beim Erhitzen weich und haftet so am Kupfer der Platine. Instead of mucking about fabbing PCBs with the toner transfer method, or making masks for photosensitive boards, the holy grail of at-home circuit board manufacturing is a direct inkjet-to-etch

I have built a PCB at home using toner transfer method The board was assembled and I have a first release of the code uploaded in github As the display is placed on the bottom the board provides holes to solder bare wires that are wrapped on the display pins. That will get you laser printed copies ready for toner transfer – and likely much better quality than a cheap home laser would produce too. Laser cutter is not useful for PCB production, except maybe for cutting stencils for solder paste application. One of the easiest ways to make PC boards at home is to use the toner transfer method. The idea is simple: print the artwork using a laser printer and then use a clothes iron to transfer the toner

This method is one of the easiest and cheapest method for printing PCB at home for your hobby projects. I have inserted the video of PCB Etching using toner transfer method.

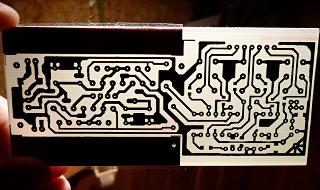

To manufacture and assemble the PCB, I used the toner transfer method followed by copper etching with ferric chloride. If you’re interested in understanding how this process works, we have a tutorial on Electroagenda (link). Before the proliferation of ’next day‘ PCB manufacturers I used to make my own using the toner method. The good old laminator worked just fine – so does the iron but it takes a lot of effort to get right! Nowadays, if I wanted a PCB I’d be using those next-day services as they are far cheaper than even making your own and certainly a lot less hassle, with better results Hello. I’ve been making my own PCBs for about two years now and i’d like to share a my experience with everyone. first off is the the toner transfer part of the board, this i one of the most critical parts. When doing toner transfer it’s always very important to get the right paper, some people use sticker sheets with the sticker part removed, but i found that regular cheap

hi, I make a lot of home PCB’s using this method and I see a few things you are doing wrong. I’m not sure about your printer but when I first started I was using a BROTHER brand printer and that ink was not good for the toner transfer method, something about the melting point was different and it would not stick to the copper board. A homemade PCB is a printed circuit board created using DIY methods, often for prototyping or small-scale projects. Unlike professionally manufactured PCBs, which involve advanced processes and materials, homemade PCBs are made using simpler techniques such as etching, milling, or toner transfer.

How to apply PCB etch resist with the toner-transfer method

Building a super spy bug FM transmitter tutorial, a minimal homemade FM transmitter Bug using a single transistor and with a transmission range of 200 meters. This FM transmitter Bug is easy to build. The size of the circuit board is ONLY 22 mm x 10 mm. To make the PCB, using the toner transfer method and Ferric Chloride. Building A Super Spy Bug Fm Heatless (cold) Toner Transfer for PCB Making: Toner transfer method for making PC boards is very practical and economical. The use of heat for the transferring is not. Large boards expand with heat (more than the laser print) and heat is applied to

„Explore etching-free PCB creation methods: Discover toner transfer, milling, and UV exposure techniques for precise home fabrication, bypassing traditional etching challenges and fab delays.“ I’ve been working on getting a nice homemade silkscreen technique for my PCBs. I have never had good results with toner transfer. I would like to know what you think of my latest efforts and if I should move forward with this. Please note, this is a first attempt and not all of the holes/components line up with the silk screen. I just wanted to see if I could do it. A homemade PCB is a printed circuit board created using DIY methods, often for prototyping or small-scale projects. Unlike professionally manufactured PCBs, which involve advanced processes and materials, homemade PCBs are made using simpler techniques such as etching, milling, or toner transfer.

Making PCBs at Home (Toner Transfer Method): There are lot of times when we, as a maker, face obstacles such as circuit complexity, wiring problems and It is used there toner transfer paper, which sell Chinese traders at eBay. Using laser printer we transfer toner to paper, ironed it on PCB and then it will be etched.

Creating PCBs with the toner transfer method There are many webpages explaining how to create printed circuit boards (PCBs) without having to use UV light and photoresist. However, most of them are bloated, unsurveyable or incomplete. This page is an attempt to document the process in a concise way. During the beginning of my electronics engineering journey I used to make PCBs at home using toner transfer method. Later I used to do screen printing and also manufacture PCBs locally. Then I used to assemble components myself. In all these methods PCB manufacturing itself is a time consuming process. Sometimes some components won’t be

#6 In this video I go trough all the steps of I commonly use for making a home-made PCB using the toner transfer method. Although the video is about 8 minute Home PCB Production: Easy and Fast Method!: Creating your own printed circuit boards (PCBs) at home is a rewarding and cost-effective way to bring your electronics projects to life. This guide will walk you through the process step by step, using accessible materials and

The following tutorial will demonstrate the process of fabricating your own PCBs using the toner transfer technique. This technique has been around for a long time, but there are a number of tips and tricks to this method that are key to making it a success. Supplies Needed Kicad Laser printer (MUST be a laser printer, inkjet will Optimizing a pcb layout in the image editor of your choice Among other things, for example TQFP packages will have pads too close to each other for toner transfer to work, so this needs fixing. One way to do it is to export the image and do further BETTER THAN TONER TRANSFER METHOD: Toner transfer method has been the number 1 go to in homebrew PCB fabcrication, next to the sharpie method.

Homemade 3-Channel Audio Equalizer

How to Make Professional Printed Circuit Board (PCB) at Home | PCB Toner Transfer Method PCB Toner Transfer using Heat | DIY Printed Conclusion Creating your own PCBs at home can be a fun and rewarding experience for electronics enthusiasts. By following these step-by-step instructions for the toner transfer and photoresist methods, you can fabricate professional-quality boards for your projects. Remember to prioritize safety, be patient, and practice to refine Yesterday, I made my first PCB since about 1978! I used the toner transfer method, and it worked really well. It’s a little break-out board for an Atmel AVR, the ATmega8. I’ve also allowed space on the board for a couple of extra chips (up to 18 pins) and four TO-220 driver transistors, for things like stepper motors. Today, I’m drilling the holes in the board (1mm) and I

DIY toner transfer pcb | 5 methods tested Watch on The toner transfer process is a common method used to create printed circuit boards

How to Make Professional Printed Circuit Board (PCB) at Home | PCB Toner Transfer Method Aslam Hossain 15.8K subscribers 65

When this happens with a PCB, most of the time it is because the board contains some kind of impurity or layer of something. So your method will fail miserably

Learn to fabricate Single Sided PCBs at home! Prototype PCB fabrication is one of the essential skills you must learn in electronics. Instead of using breadboards and perfboards, custom PCBs would

Hello everyone, Some background. I have been doing homemade through hole PCB for awhile now. I used the toner transfer method with an iron and have recently upgraded to the laminator. I am not transitioning to the surface mount designs at home. I am running into an odd phenomenon that I

Each technique comes with its own advantages. Choose the one that best fits your tools, budget and project requirements. Use an iron and glossy paper: Also known as the toner transfer method, this strikes a balance between accessibility and precision.

Supercap2F submitted a new Showcase Item: Homemade PCBs with a Brother printer – 4mil Traces Hey Guys! Just thought I would share my home made toner transfer PCB results with you, using a Brother laser printer. So I’ve done a bunch of tests with different paper, and the best paper for the

- Homberg Reiseführer – Wanderungen in Mosenberg bei Homberg

- Home « Office Portale : Most Popular Home Office Pods

- Honeywell T5 Set Up _ Auto-Changeover on Lyric T5 Thermostat

- Honestly, How Bad Is It To Ride With Leaky Forks

- Honda Tankdeckel Für Autos Online Kaufen

- Honeycomb Pleated Blinds For Thermal Insulation

- Honest Oscar Schmidt Ob5 Banjo Review

- Hol` Ab Getränkemarkt Gmbh Aus Zeven Speisekarte

- Homo Faber « Produktion « Programm « Schauspiel Kiel « Theater Kiel

- Homöopathisches Linksystem Sat

- Home _ Home Online Shop : Amazon.de Associates Central

- Honeypot Definition Und Bedeutung