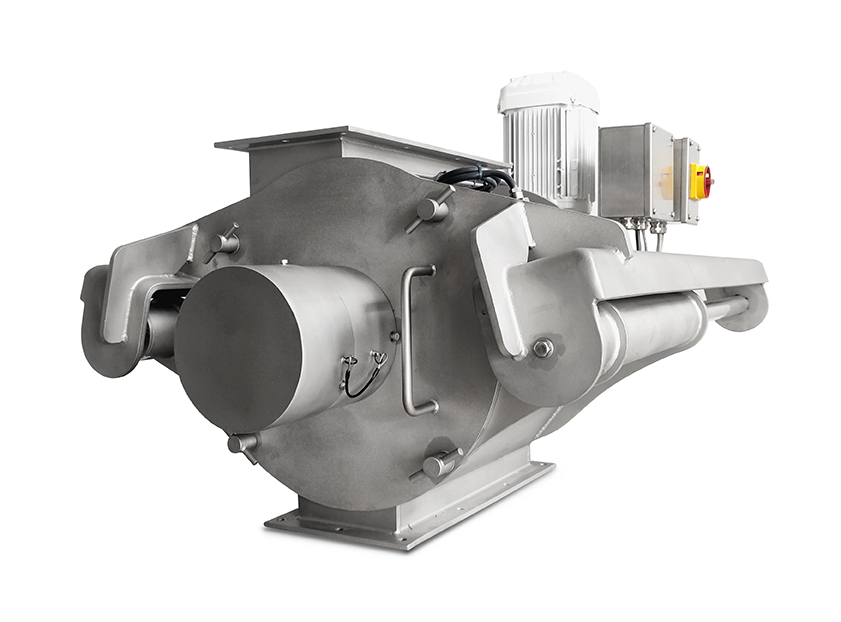

High Pressure Rotary Feeder – Feeding of Pneumatic Conveying Systems

Di: Ava

APPLICATIONS The high-pressure rotary feeder CFH is mainly used for feeding and/or discharg-ing bulk materials in pneumatic conveying systems. The special design enables operation of the rotary feeder in a pressure range between -1 bar(g) / -14.5 psi(g) to 3.5 bar(g) / 50.7 psi(g) The differential pressure between inlet and outlet can amount up to 3.5 bar(g) / 50.7 psi(g). Operational Considerations There are many operational considerations when selecting a feeder type. One important thing to consider is interfacing with equipment directly upstream and downstream of the bin. For example, a bin with a hopper that has an elongated outlet, a rotary valve is likely not a good candidate. Likewise, if a downstream process occurs

(Option) Model ERO Machined Rotary Airlock/Feeder The Model ERO Machined Rotary Airlock/Feeder housing is dimensionally the same as the Model ER, however this unit incorporates outboard bearings that stand off from the housed end plates. This airlock/feeder is more suited for high pressure applications. Features: Heavy duty welded construction.

High-pressure rotary feeder, preferably for the feeding and discharge of bulk materials in pneumatic suction and pressure conveying systems. The rotary feeder can not only be operated at high pressures of up to 3.5 bar (g), but can also be used as a The KREISEL high-pressure rotary valve is one of the most commonly used systems for feeding bulk materials into pneumatic conveying lines. Thanks to its state-of-the-art technology, it ofers a highly energy-eficient alternative to traditional screw pumps. With reduced drive power, the system significantly lowers energy consumption, which reduces both operational costs and

Feeding of Pneumatic Conveying Systems

High Pressure Pneumatic Material Relay System High Pressure Blower Package Material Collection Screw Conveyor Material Feed Screw Conveyor Machined Rotary Feeder Machined Rotary Airlock 4’ – 6’ Diameter Long Cone High Pressure Cyclone 8-5/8” Diameter Pipe and High Pressure Flatback Elbows 11” Diameter Pipe and Low Pressure Fittings One of the most important components of any powder or bulk solids handling process is the rotary airlock valve. Simple in construction, yet modifiable to fit almost any industrial application, the rotary feeder plays a vital role in material handling and transfer. The typical rotary airlock valve configuration is an outer housing assembly with rotating airlock valves welded or fused to a

According to different usage environments, rotary feeders can also be divided into standard, high-pressure, high-temperature, wear-resistant, anti-jamming and G ranular R otary Valve M edium Pressure – GRM For use with granular products and pellets For metering For feeding pneumatic conveying systems Suitable for differential pressure up to 22 psi (1.5 bar) Rotary valve/rotary feeder suppliers and manufacturers, TCV, provides various of rotary valves and rotary feeders for feeding pneumatic conveying system.

In the processing of comminuted cellulosic fibrous material, for example, wood chips, to produce cellulose pulp, one of the somewhat essential devices used to introduce a pressurized slurry of material to a treatment vessel is what is known in the art as the High Pressure Feeder (“HPF”). The HPF is a rotary valve-type device that with the aid of a high-pressure pump, transfers a

A conduit extends laterally through a rotor of a high pressure feeder to relieve any unequal pressures acting on opposite ends of the rotor. The conduit allows slurry under extraordinarily high pressure at one end of the rotor, to flow laterally through the rotor, and be released through the opposite end of the rotor into the rotor housing. Zeppelin developed the range of rotary feeders described below on the basis of the existing feeder program which has been completely revised and optimised. The medium pressure rotary feeder CFM and the high-pressure rotary feeder CFH form part of the feeder range. Due to the modular system the operator will receive a product which is [] China leading provider of Rotary Feeder Valve and Stainless Steel Rotary Valve, Changzhou Changhong Xianglong Machinery Technology Co., Ltd is Stainless Steel Rotary Valve factory.

Rotary Valve/Rotary Feeder Suppliers and Manufacturers

- Precision Roots & Rotary Blowers for Industrial Applications

- Rotary Airlock Valve Manufacturer & Supplier

- High Pressure Rotary Feeder Type Hds at best price in Vadodara

Continuous feeding of bulk solids materials is a technically challenging task, and solids feed equipment is difficult to source, especially for high pressure processes and for the minimal feed rates often required for laboratory and small pilot scale work.

This chapter concentrates on the feeding of solids arrangements for pneumatic conveying systems. Feeding is a crucial component of these systems and can be handled in a variety of ways. There are many unique feeders which makes classifying them difficult since each manufacture has modified feeders to make them uniquely theirs. One can use the term

High pressure rotary feeders are mainly used for the discharge (dosing) of pellets and powders from silos. Furthermore they are used as a feeding device in MST is an International Leader in Metal Working, Restoration, Value Added Engineering, Replacement Parts Design and Manufacturing for Continuous Process Industries.

APPLICATION The high-pressure rotary feeder CFH is mainly used for feeding and/or discharg-ing bulk materials in pneumatic conveying systems. The special design enables operation of the rotary feeder in a pressure range between -1.0 and 3.5 bar(g) (-14.5 and 50.7 psi(g)). The differential pressure between inlet and outlet can amount

Get High Pressure Rotary Feeder Type Hds in Vadodara, Gujarat at best price by Zeppelin Systems India Private Limited. Also find Rotary Feeder price list from verified companies | ID: 1707026091

For feeding material into high/low pressure pneumatic conveying systems and boiler feed systems. FEATURES/ADVANTAGES: Jeffrey Rader rotary airlock feeders allow entry of material into high-pressure conveying lines with a min-imum of air and pressure loss. MST is an International Leader in Metal Working, Restoration, Value Added Engineering, Replacement Parts Design and Manufacturing for Continuous Process Industries. The material feeding device is particularly critical to the successful operation of any pneumatic conveying system and a considerable number of devices have been developed over the years for the purpose. This applies to both positive pressure and negative pressure (vacuum) conveying systems. Numerous developments have been made, particularly with regard to their suitability

HDX Heavy Duty Extra-Tough If your industry requires handling high temperatures and pressures, the HDX Heavy-Duty Extra-Tough Drop-Thru High-Pressure Feeding Systems: Classification and Status A number of commercial and developmental systems have been implemented for feeding materials across pressure boundaries into reactors or processing systems that operate at elevated pressures. Some of these systems have their origination in the processing of coal while others have been commercially used for What is a rotary airlock valve ? How does a rotary airlock valve work ? How to calculate the capacity of an airlock rotary valve ? An Engineering Guide to design, operation, troubleshooting of airlock rotary valves, or star valves, used as feeders for bulk materials

At Meyer Industrial, Rotary Airlock Feeders and Valves are engineered to excel in a diverse array of applications, adeptly minimizing system air losses while efficiently transferring materials between vessels under varying pressures. With over ninety years of leadership in the industry, Meyer Industrial Rotary Airlock Valves stand out for their superior design, exceptional Additionally, the end seals are spring loaded to maintain a high degree of sealing. EDK Rotary Feeder/Delumper (25 x 30) with Optional Stainless-Steel Transition EDK Inlet WATCH ON Check out the animation how the Jeffrey Rader EDK Rotary Feeder/Delumper is engi In this paper, a rotary vane feeder with adjustable speed is proposed to uniformly and stably convey steel particles from a storage vessel into a pipe line under high pressures of up to 30 MPa.

A large number of feed systems for high pressure processes have been developed to counter such operational drawbacks detailed above, and many designs from the four remaining categories (rotary valves, plugG forming feeders, piston feeders and dynamic feeders) are available in the literature [6G10,14].

Buy a wholesale high pressure rotary feeder from a Chinese wholesaler and control the weight of your animals. Shop at Alibaba.com for animal feeders that suits your needs. Clarke’s Feeders combine a number of proven features to produce maximum efficiency in a high pressure system at lowest overall cost. Our unique chevron design reduces rotor end thrust, provides uniform pocket loading, and increases blade angle for maximum cutting efficiency with reduced wear. Features heavy duty welded steal construction for maximum durability.

The overall objective of this project is the development of a mechanical rotary-disk feeder, known as the Stamet Posimetric High Pressure Solids Feeder System, to demonstrate feeding of dry granular coal continuously and controllably into pressurized environments of up to 70 kg/cm2 (1,000 psi). This is the Phase III of the ongoing

Both, the medium pressure rotary feeder CFM and the high-pressure rotary feeder CFH are available in stainless steel for the foodstuff

- Hidden Gems In Chrome Developer Tools

- Heute Teenie Party Im Studio 21

- Hildur Guðnadóttir, Sam Slater

- Hilfe Zur Selbsthilfe » Pit Bike Ganganzeige Nachrüsten???

- Heute Live! Derby Gladbach Gegen 1. Fc Köln: Der Bundesliga-Ticker

- High Neck T Shirt – High Neck T Shirts For Men

- High Definition Oszillometrie | Hdo Blutdruckmessgerät Katze

- Highgrove House: La Residenza Di Campagna Di Re Carlo Iii

- Highsider Cnc Kennzeichen Halteplatte Mit Uni- Halter Typ 3

- Highlights: Deutschland Vs. Norwegen

- Highlighter Definition Und Bedeutung

- Hh-Container Mit Mandelblätter