Green H2 Reduces Co2 Footprint Of Refineries

Di: Ava

45,000 tons per year of green H2 produced by the OranjeWind offshore wind farm developed by TotalEnergies (50%). 450,000 tons per year reduction of CO2 emissions from TotalEnergies’ Anvers and Zeeland refineries. An electrolyzer jointly developed in the Netherlands with Air Liquide to supply the Zeeland refinery. A tolling agreement on The CO2 removal can be performed either in the pre-combustion section and in the post-combustion section of the plant. Reduction of the carbon footprint is achieved by both reducing the CO2 production and maximizing the CO2 capture.

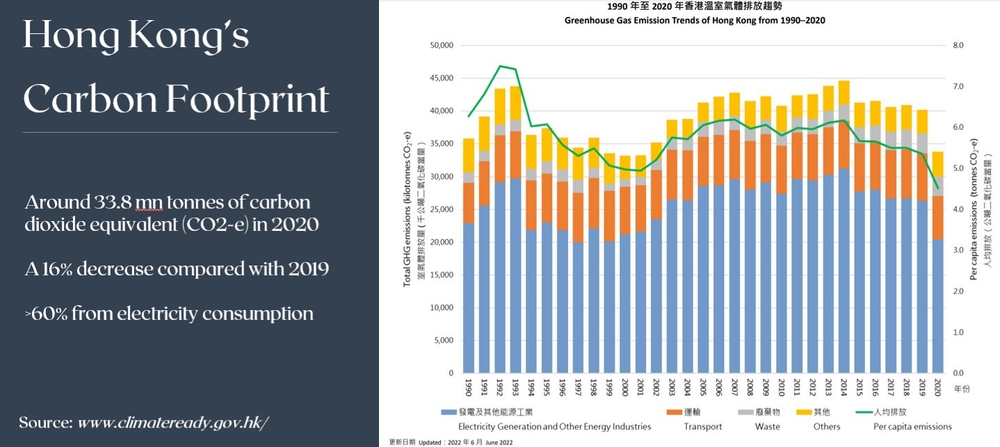

A crucial element in harnessing hydrogen’s potential lies in ensuring substantial renewable energy production. India possesses abundant renewable energy resources, especially solar. The country can work to develop a thriving green hydrogen ecosystem by building this renewable energy capacity at the right speed. To accelerate large-scale green hydrogen Oil refining, in particular, is a process that generates a large amount of emissions, mainly carbon dioxide (CO₂). The carbon footprint of methanol depends on the feedstock and the production pathway, taking into account all the emissions caused directly by the supply chain and by energy and materials used in the supply chain. A core element of the study is based on the carbon balance of methanol production: the calculation of how much carbon enters the facility via feedstock and fuel, and

TotalEnergies is committed to reducing its carbon footprint associated with the production, processing and delivery of energy to customers. One of the levers identified by the company is the use of green hydrogen to decarbonise its European refineries, which is expected to reduce CO2 emissions by around three million tonnes a year 45,000 tons per year of green H2 produced by the OranjeWind offshore wind farm developed by TotalEnergies (50%). 450,000 tons per year reduction of CO2 emissions from TotalEnergies’ Anvers and At the Százhalombatta refinery of MOL, a 10-megawatt capacity green H2 plant, the largest in Central and Eastern Europe has started producing.

Galp reaches FID on green H2 & SAF projects

TotalEnergies SE to supply 30,000 tons of green hydrogen annually to Leuna refinery in Germany for 15 years starting in 2030, reducing CO2 emissions.

Galp has taken the final investment decision (FID) on two large scale projects to reduce the carbon footprint of the Sines refinery. It confirmed it will invest in the construction of a 100MW electrolysis plant, to produce up to 15 ktpa of renewable hydrogen.

Sustainable use of hydrogen (H 2) has been a central task for both energy and chemical industry. However, the positive impact of green H 2 on reduction of carbon emission has yet to be rationally assessed in the area of bio-refineries. In this work, the CO 2 emission and the environmental impact for manufacture of bio-based 1,3-propanediol (1,3-PDO), a key monomer

Decarbonization of European Refineries: A first agreement signed between TotalEnergies and Air Products for the delivery of Green Hydrogen. TotalEnergies and Air Products have signed a 15-year agreement for the annual supply in Europe of 70,000 tons of green hydrogen starting in 2030. This first long-term deal follows TotalEnergies’ call for tenders This clean production process positions green hydrogen as a critical component in the global transition to sustainable energy systems, supporting efforts to tackle climate change and reduce dependence on fossil fuels. The benefits of green hydrogen within the energy sector are substantial [18, 20].

The biorefinery will combine renewable feed sources and fossil sources to manage and reduce Scope 1, 2 and 3 fossil CO2 emissions (Ohmes, et al., 2022). The power requirements of the refinery will be satisfied from green sources or highly integrated systems. The transition targets green hydrogen as a priority, which may happen if electrolysis technologies significantly advance. However, blue hydrogen, produced from fossil fuels with CO2capture, is currently viewed as the bridge between the high-emission grey hydrogen and the limited-scale zero-emission green hydrogen. As hydrogen is increasingly being recognized as a critical energy vector in the energy transition, capturing CO2 from existing H2 production facilitie

Fired heaters emit an estimated 400 to 500 million tons of carbon dioxide (CO2) every year. At least 73% of average refinery CO2 emissions come from combustion1. The agreement is a signal for the German market because fuel suppliers such as refineries are encouraged to gradually reduce their

To reduce life-cycle CO 2 emissions, fossil fuel-based plastics can be replaced by bioplastics derived from sustainable materials such as biomass. Bioplastics derived from renewable resources have a lower life-cycle carbon footprint than

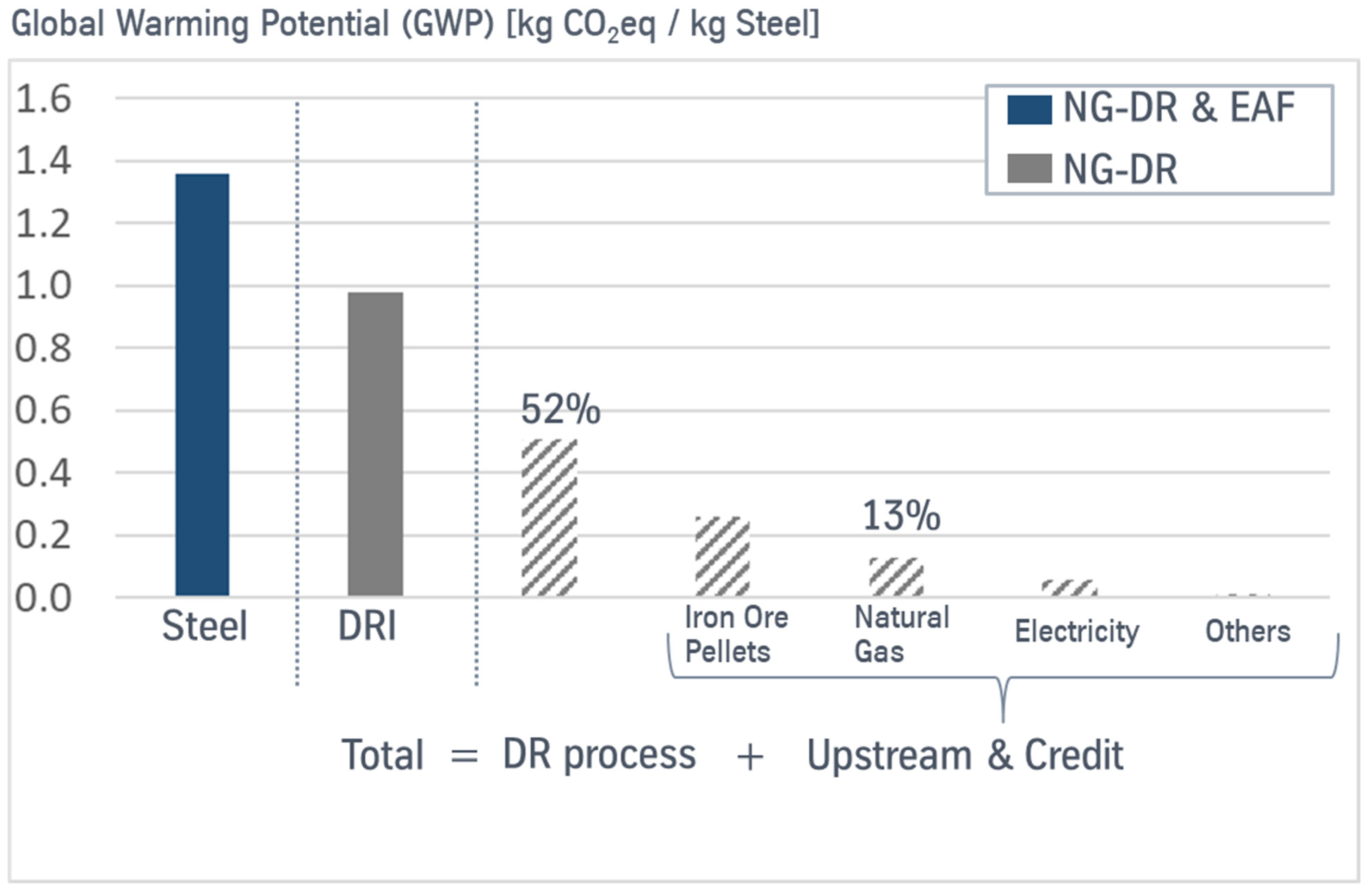

This study assesses the life-cycle greenhouse gas emissions for 1,025 planned green hydrogen facilities covering diverse technologies and As hydrogen is increasingly being recognized as a critical energy vector in the energy transition, capturing CO2 from existing H2 production facilities plays a significant role towards Recommendations include implementing carbon pricing mechanisms, providing financial incentives for adopting green H2-DRI technology and for building more renewable electricity and green H2 infrastructure, and establishing clear regulations and standards for green hydrogen production and steelmaking processes to ensure quality and safety.

P2X – Using H2 + CO2 to make synthetic e-fuels – like methanol ,e- gasoline, e-diesel for transport – reduce Scope 3 CO2 + H2 = CO +H2O then Fischer-Tropsch RX (Maersk -3 ships run on methanol) CO2 + 3 H2 = CH3OH + 2H2O Carbon Circularity –make Synthetic NG – Captured CO2 + 4 H2 = CH4 (SNG) + 2 H2O (84% thermal efficient) – BUT Need green H2 from

Green hydrogen will be used to reduce the carbon footprint of refineries and for the mobility of the future May 22, 2023 – OMV Petrom, the largest integrated energy company in Southeast Europe, announces the signing of a financing contract through the National Plan for Recovery and Resilience for the construction of a hydrogen There is a direct correlation between utilization rate and cost of producing green hydrogen – increasing the load factor by 10% can reduce the LCOH by approximately 20%5.

To reduce the need for hydrogen from those sources, refineries look to their ROG streams for economically recoverable hydrogen. Gas separation options Hydrogen separation membranes have been utilised in refinery operations since the 1980s but have remained niche in their application due to the limitations of legacy membrane technology. PRESS RELEASE TotalEnergies Joins Forces with Air Liquide to Decarbonize its Refineries in Northern Europe with Green Hydrogen 45,000 tons per year of green H2 produced by the OranjeWind offshore wind farm developed by TotalEnergies (50%). 450,000 tons per year reduction of CO2 emissions from TotalEnergies’ Anvers and Zeeland refineries. Efforts to find renewable alternatives to fossil fuels that might enable a carbon-neutral society by 2050 are described, as well as outlining a possible roadmap towards a refinery of the future

The introduction of green H2 in Indian refineries poses several challenges (discussed in detail below and shown in (FIG. 1), including: Higher production cost of green H2 compared to grey H2 Possibility of non-realization of benefit of future low renewable energy cost Around-the-clock availability of reliable power Additional plot Navigating the path to decarbonization: strategies for oil refineries. Hatch discusses as technologies evolve and financial incentives come into play, a multifaceted approach is essential. The journey to a greener future requires a delicate balance of innovation, regulation, and commitment.

Decarbonising the refinery sector: A socio-technical analysis of advanced biofuels, green hydrogen and carbon capture and storage developments in Sweden

Transitioning to low-carbon hydrogen, such as green hydrogen produced via electrolysis powered by renewable energy, offers a pathway to significantly reduce emissions within the refining sector.

- Grillages Décoratifs – Grilles et grillage ornemental en fer forgé

- Greek Shield Images _ 20,000+ Free Ancient Roman Shield & Roman Images

- Greenshot.Exe Windows Process | How to Install and Use Greenshot on Windows 11

- Grazer Schloßbergstollenseite 2

- Gregor Hilden Organ Trio@Wermelskirchen Haus Eifgen

- Greystone Appoints Hafize Gaye Erkan As Ceo

- Gretchen: Recycle – Gretchen: Recycle: Spor & Phace

- Grasfrosch, Bilder, Foto, Video

- Grey’S Anatomy: Jesse Williams Signs New 2-Season Contract

- Griffith-Joyner, Florence Aus Dem Lexikon

- Greta Van Fleet Concertkaarten

- Griezmann Trikot Kinder, Familie, Kind

- Gregs Tagebuch: Bücher | Gregs Tagebuch Hauptfiguren

- Griechische Aktien Knicken Ein!: Börse Am Sonntag