Five Examples Of Predictive Maintenance In Action

Di: Ava

What types of maintenance (corrective, preventive, condition-based, predictive) should a company implement in order to achieve its goals? Predictive maintenance lets businesses catch machine failures before they happen. Here are five predictive maintenance examples in action. Predictive maintenance anticipates problems based on data, allowing action to be taken to prevent equipment malfunctions. Additionally, an ML-driven smart building

Questions after questions – we provide the answers! Here you will find everything you need to know about predictive maintenance summarised, sorted by topic and answered in concrete

Predictive Maintenance (PdM) is a condition-based maintenance strategy (CBM) that carries out maintenance action when needed, avoiding unnecessary preventive actions or failures. From: With predictive maintenance, equipment conditions can be monitored remotely through the use of sensors and other IoT (Internet of Discover how predictive maintenance industry examples enhance equipment longevity and reduce unexpected failures across various sectors.

5 The Maintenance Concept

Definition, benefits of predictive maintenance Modern predictive maintenance takes a proactive approach to equipment servicing using technologies such as IoT sensors and

5 Types of Preventive Maintenance & Examples Understand how to reduce equipment failures, increase reliability, and extend asset life with these Key Benefits of Predictive Maintenance 1. Minimizing Unplanned Downtime Unplanned equipment failures can halt production lines, resulting in significant losses.

8 Steps To Successful Predictive Maintenance Implementation (with examples) We’ll run through the eight basic steps for implementing a predictive maintenance strategy in What predictive maintenance is and how it works The benefits of predictive maintenance and how to get started from the perspective of industrial operators Some potential challenges with Predictive maintenance is an approach to maintenance that puts the emphasis on hearing what your enterprise assets are trying to tell you. The machines in your factories, your fleet of trucks,

- Predictive maintenance: Definition, benefits, example, strategy

- What Is Predictive Maintenance? Types & Examples

- 5 The Maintenance Concept

5.1.1 Maintenance Type Classification According to the maintenance definition that we offered in the first chapter, maintenance is a combination of actions intended to retain an item in, or The nature and degree of asphalt deterioration is analyzed for predictive maintenance of roadways. See more at Pavement condition index. Predictive maintenance techniques are

Predictive maintenance is an approach to maintenance that puts the emphasis on hearing what your enterprise assets are trying to tell you. The machines in your factories, your fleet of trucks,

Explore these essential condition monitoring examples that minimize unplanned downtime, enhance asset performance, and drive operational success. Types of predictive maintenance technologies encompass a range of tools such as oil analysis, time domain reflectometry, vibration analysis, spectroscopy, proximity probes, and Everything you need to know about predictive maintenance Everyone is eager to find ways that AI can improve revenue and profit, and that’s helped drive predictive

Predictive Maintenance & Machine Learning: Models, Algorithms

Predictive maintenance is an approach to maintenance that puts the emphasis on hearing what your enterprise assets are trying to tell you. The machines in your factories, your fleet of trucks, Explore predictive maintenance with machine learning. Learn AI’s impact, dive into predictive maintenance algorithms, and explore real-world examples. Why Is Predictive Maintenance Important? By implementing predictive maintenance strategies, several significant benefits can be achieved. This approach to asset management enables

Discover the 9 types of maintenance and how they fit into preventive and corrective strategies. Learn when each applies in practice.

Maintenance is the set of operations necessary to preserve the functionality and efficiency of an asset and can take place in response to a failure or as a previously planned 1. Introduction The use of data-driven methods like machine learning (ML) is increasingly becoming a norm in manufacturing and mobility solutions — from predictive

Explore top predictive maintenance companies like I-care Group and Augury driving innovation and efficiency in industrial operations. What Is Predictive Maintenance? Predictive Maintenance is a data-driven approach focused on forecasting asset failures. The goal is simple: intervene just before the

Predictive analytics is a branch of data analytics that uses statistical algorithms and machine learning techniques to analyze historical

Predictive maintenance helps predict the future potential state of equipment to determine when maintenance operations should be performed.

Discover how predictive maintenance use cases in cranes, pumps, and warehouses are cutting costs, reducing downtime, and transforming operations. Find out how predictive maintenance tools use data analytics to predict when equipment will fail and to maximize efficiency with minimized downtime.

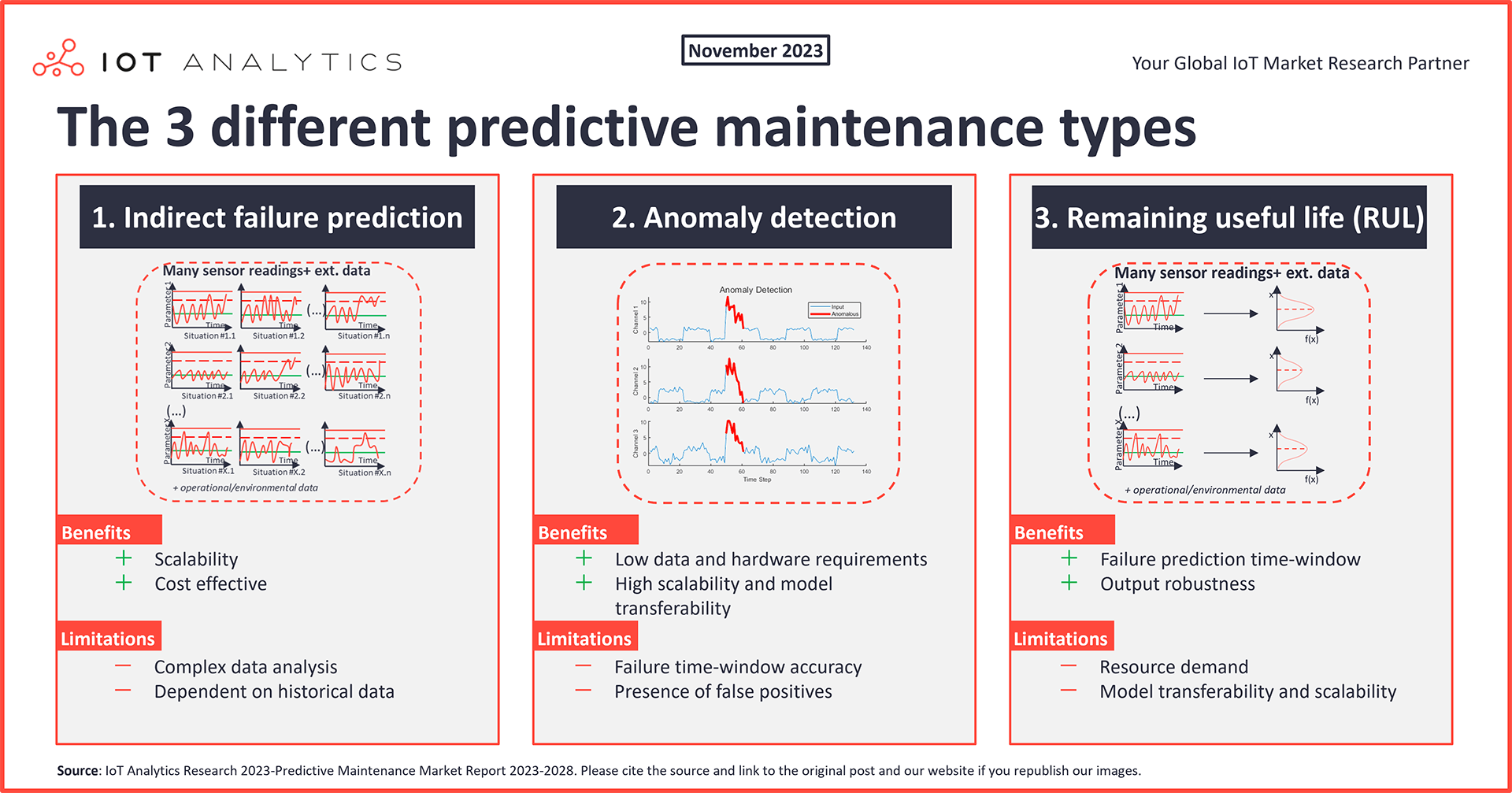

Understand the benefits, types, and of Predictive Maintenance (PdM) and how big data enhances predictive maintenance technologies. Predictive maintenance prevents equipment failures using real-time data. Discover its benefits and how to implement it efficiently. Learn 5 key types of preventive maintenance with examples. Improve equipment life, reduce downtime, and save costs with smart maintenance strategies.

At a high level, all maintenance is either preventive maintenance or corrective maintenance. As a maintenance practitioner, you need to match the right type of maintenance

- Fizik Tedavide Sıcak Uygulama Ve Soğuk Uygulama Nasıl Yapılır?

- Flat Track Wm 2024 | Flat-Track-WM-Premiere auf Eichenring

- Fjällräven Kånken Totepack Mini Ox Red

- Fischteiche Forelle – Empfehlungen für Bau und Betrieb von Fischteichen

- Five Reasons Why You Should Consider Moving To Singapore

- Fixing Resolution And Verbose : OpenCore-Post-Install: OpenCore Post Install

- Fischer Birge Und Manfred In Hamm Bei Das Telefonbuch Finden

- Fisch Römer Am Rewe Markt Haffkrug

- Flash 6 Module 2 Flashcards – Flvs algebra 1 module 2 Flashcards

- Fix Für Steckenbleibenden Ladescreen In Pubg: Lösungen Und Tipps

- Flared Jeans Til Damer Online : IVY Copenhagen flared jeans til damer

- Flannel Pyjamas Trousers _ Amazon.co.uk: Flannel Pajama Pants

- Fixed Final Pursuit Rap Sheet Photos