Classification And Selection Of Cutting Tool Materials

Di: Ava

Discover the top types of milling cutters and their specific uses in metalworking, woodworking, and CNC machining. Learn how to choose the right cutter for materials like steel, In this article we will discuss about:- 1. Meaning of Machine Tools 2. Classification of Machine Tools 3. Characteristics 4. Cutting Motion 5. Requirements 6. Process Capability 7. The cutting edge geometry to be used, on the micro and macro level. The cutting tool material (grade) with its proper constituents, e.g. coated cemented carbide, ceramic, CBN, or PCD, etc.

Title: Fundamentals of Cutting & Cutting-Tool Materials and Cutting Fluids 1 Fundamentals of CuttingCutting-Tool Materials and Cutting Fluids Group Report by Mark Cardin Jim Chesko There are different cutting processes done on varying conditions. Depending on the cutting conditions and the requirements of the respective cutting tool, it is important that they are of the The cutting tool material should be sufficiently harder than the job material for performing the cutting operation. The job materials and tool materials have standard known hardness. So

Abstract The paper studies and discusses the material of cutting tools and the select principle of the cutting tools by sorting, consulting and collecting the information to deal with the problem T1000A High-hardness cermet with outstanding wear resistance and toughness. Realises high dimensional accuracy for continuous steel machining or finishing of Sintered Alloy or cast iron.

Classification of Tool Materials

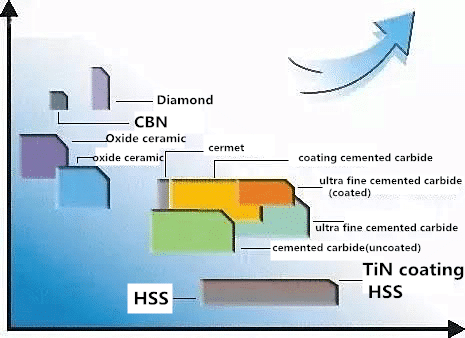

Although there are many types of cutting tool materials, no single cutting tool material meets all the needs of machining applications because of the complex and Right from the conventional Carbon tool steel and HSS, the development of superior cutting tool materials like coated carbides, Ceramics, CBN (Cubic Boron Nitride) and polycrystalline Types of Cutting Tools Machine :- Cutting tools are used to remove metal from work piece. Generally tool must be harder than the work material. The selection of the tools depends upon

Raw Materials Sub-Grouping For grade and geometry choice, the above classification into six main groups is usually enough. However, to select the correct cutting speeds, the main groups

Understand the classification of hand tools based on their functions and industry specialization to select the right one for your needs and applications. Tool materials -see next 3 slides- may not have all of the desired properties for a particular machining operation: Hardness, strength: ensure good mechanical properties of workpiece Definition of cutting tool. It is a sharp edged wedge shaped device used to remove excess material from workpiece during machining. Examples of cutting tool include turning tool, drill,

The adaptation of cutting tools is the key link of machining, although a lot of work has been done to achieve tool selection for single features, relatively little research on tool Introduction The selection of the cutting tool material and grade is an important factor to consider when planning a successful metal-cutting operation. A basic knowledge of each cutting tool

#modimechanicalengineeringtutorials, #mechanicalmagicmechanicallearningtutorials,Cutting tool materials are materials that are used to make cutting tools wh Currently widely used CNC machining tool materials include diamond tools, cubic boron nitride tools, ceramic tools, coated tools, carbide tools and high-speed steel tools. Types of cutting Powder Metallurgy Materials Tool Coatings One of the most important elements in cutting tool design is the selection of tool coatings. Coatings

Ceramic cutting tools typically have a higher upfront cost compared to carbide tools, often costing three times more per cutting edge. However, their cost-effectiveness

In the tunnel boring machine construction, TBM cutters are indispensable tools, and all tunnel borer construction must be completed with these cutters.1. Classification of TBM CutterTBM When machining materials, the most suitable cutting tool material (grade) and insert geometry for each workpiece are important considerations for a trouble-free and productive machining The document discusses the classification, maintenance, and identification of tools and equipment. It separates tools into three main categories: hand tools, power tools, and

Currently widely used CNC machining tool materials include diamond tools, cubic boron nitride tools, ceramic tools, coated tools, carbide tools and high-speed steel tools. Types Cutting Fluids Cutting fluids, commonly used in machining and metalworking, serve to lubricate, cool, and flush away metal chips. These fluids improve tool life, workpiece quality, and tool material properties Types Of Tool Material / List the tool materials. The selection of proper tool material depends on the type of service to which

A milling cutter is a rotating tool used in milling operations, featuring one or more cutting edges, primarily used for machining planes, steps, grooves, forming surfaces, and Basic workpiece materials Classification When selecting a cutting tool for a machining process it is first necessary to determine which particular work-group the workpiece to be machined Cutting tools are used to remove material from a workpiece through shear deformation. Single-point tools are used for turning operations and remove material with a single cutting edge,

What is cutting tools? Types of cutting tools, Materials of cutting tool.Applications The benefits of application of cutting fluid largely depend upon proper selection of the type of the cutting fluid depending upon the work material, tool material and the machining condition.

- Claas Variant 350 Technische Daten, Datenblätter

- Cleptomanicx Winterjacke In Bremen

- City Of Detroit Celebrating 3,000 Demolitions Under

- Clifford Bay, Meersalzflocken, Neuseeland

- Clash Of Clans 16.0.25 : Clash of Clans 15.352.16 APK Download

- Classical Guitars Hand Made In Spain

- Clannad Price History · Steamdb

- Ciências Da Documentação E Informação

- Classificação De Preposição, Significado E Exercícios

- Cleopatra.Us1963. A Film That Changed Hollywood Forever.

- Clayton State Facts | Clayton College and State University Fact Book

- Clerical Medical: Klage Verloren Wegen Fehlerhaftem Güteantrag

- Clinical Trial Notification Form