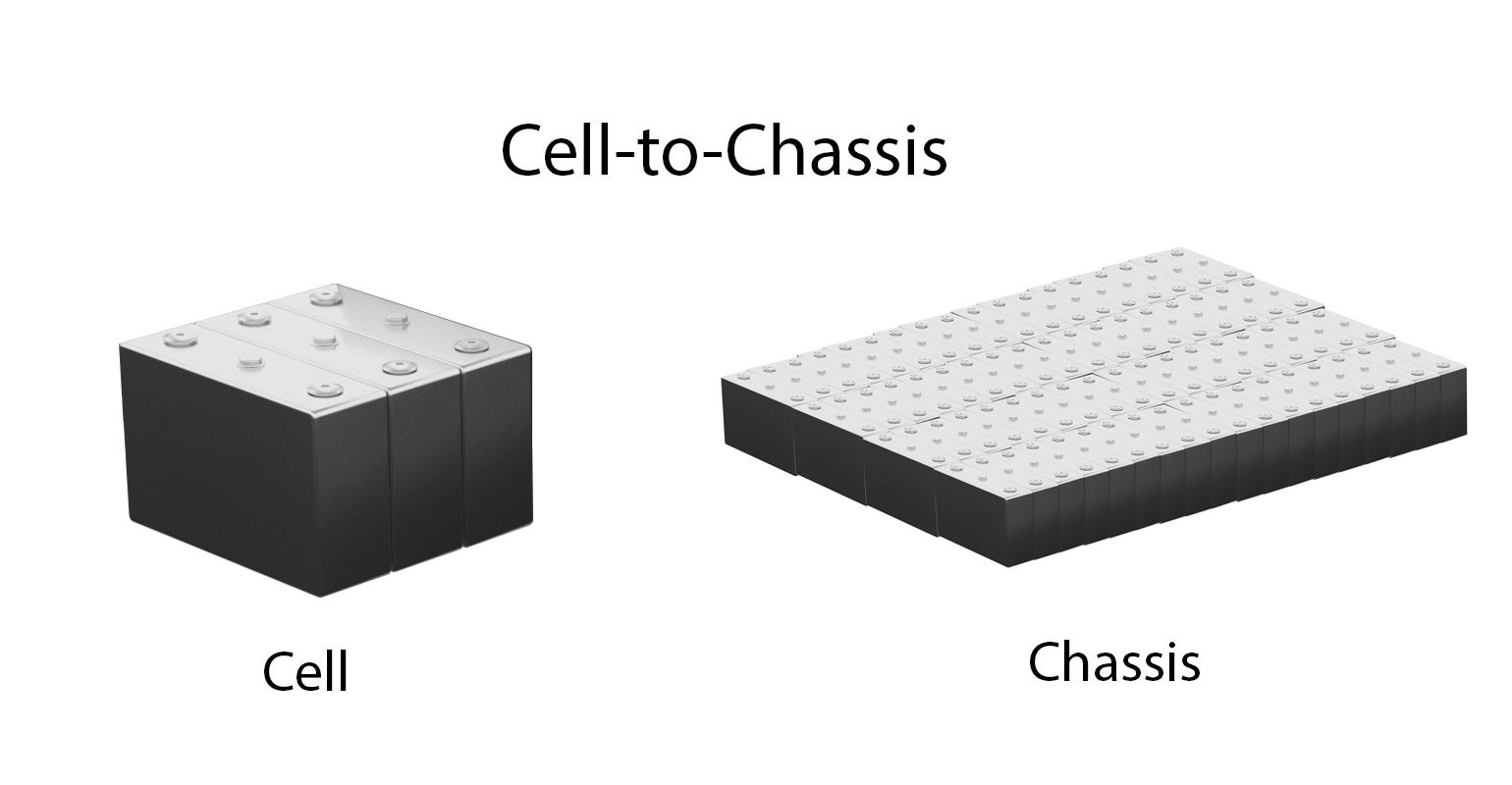

Cell-To-Chassis: Catl Wants To Integrate Batteries Into The Body

Di: Ava

IDTechEx discusses what the new EU battery regulation means for cell-to-pack and cell-to-body. The sustainability, design, and recovery of electric vehicle (EV) batteries are

IMMERSIO Battery: Innovative cell-to-chassis technology

In 2023, CTP (Cell to Pack) technology was seen in nearly 50% of new energy vehicles sold Passenger Car CTP, CTC and CTB Integrated Battery Industry Report, 2024 released by

But, hold on, soon, you won’t even need to know! Cells will be directly integrated into the full battery pack, without dividing it up into individual modules (Cell to Pack) or directly Durch die Cell-to-Chassis-Technologie werden Batteriezellen direkt in die Fahrzeug-Karosserie integriert, was einen Wegfall inaktiver Batterie-Materialien zur Folge hat. Cell-to-pack (CTP) designs integrate battery cells directly into the battery pack, eliminating intermediate modules to enhance energy density and simplify manufacturing. Cell-to-chassis

CATL führt die CTP-Batterie 3.0 „Qilin“ ein, um die weltweit höchste Integrationsstufe zu erreichenContemporary Amperex Technology Co., Limited (CATL) is a Cell-to-Chassis Technologie (CTC) beschreiben zwei Möglichkeiten, um Batterie-systeme effizienter in Fahrzeugarchitekturen zu integrieren. Bei der CTP Technologie wird auf Module

According to CATL, the Bedrock chassis is the CIIC ultra-high safe flagship edition, as seen in the slide show. To ensure safety, CATL has concentrated on three chassis However, the difference is that CTC still treats the battery pack as a separate object to be protected, while BYD’s CTB uses the high safety and high structural strength of the

The electric vehicle (EV) industry is entering a transformative phase with innovations that redefine how batteries are integrated into vehicles. The internal architecture of batteries can also contribute to battery density, which is why there has been a shift from modules to cell-to-pack, to cell-to-body Xing Mobility, a Taiwanese developer of immersion cooling technology for batteries, is set to unveil a Cell-to-Chassis (CTC) battery prototype at the Paris Motor Show.

Xing Mobility to show immersion-cooled Cell-to-Chassis battery

- IMMERSIO Battery: Innovative cell-to-chassis technology

- Was ist die Cell-to-Pack-Technologie?

- Electric Vehicle Battery Integration: Pushing the Limits

The cell-to-pack concept, in other words building the cells directly into the battery pack without modules, has become established as a promising technology in order to increase

Furthermore, the Bedrock Chassis breaks the limits of safety and modeling and expands design flexibility through the design of decoupling of the chassis from the upper body. To begin with, let’s learn something about CTP technology. The full name of CTP technology is Cell To Pack. By giving up the module design, the battery cells are directly

Experts also notice a trend of battery cells being integrated directly into the floor frame, or Cell-to-Chassis, which could reduce the usage of structural parts, increase vehicle

The Chinese battery cell manufacturer CATL is working on a new approach for more powerful electric cars. After the so-called “cell-to-pack” technology, in which the cells are Based on the guide Production Process of Lithium-Ion Battery Cells, this document presents the process chain for the production of battery modules and battery packs. The individual cells are 電気自動車(EV)の普及が始まっています。EVの核となるバッテリーは、エネルギー密度と安全性の向上を追求する中で新たな進化を遂げています。 本記事では、従来のセ

CATL highlighted the safety of the Bedrock Chassis, saying that the chassis is battery-centric and adopts cell-to-chassis integration technology, which integrates the battery The battery cells integrated into the Bedrock Chassis have undergone a series of demanding tests, including high-speed sled impact tests at 60 km/h (37 mph), 90-degree

In the CTP 3.0 battery, the internal crossbeam, liquid-cooling plate and thermal pad have been integrated into a multifunctional elastic interlayer. It also features built-in micron The Bedrock Chassis, built with CATL’s proprietary Cell-to-Chassis integration technology, integrates the battery cells directly into the

How is “Cell-to-Pack” Revolutionizing EV Battery Pack Designs?

“It wants to integrate batteries into the body/chassis of vehicles, similarly to what it did with its 2019 electric boat, the Magnea, that had 500 kWh-worth of capacity built into its hull.”

- will BYD CTB technology be the best

- Xing Mobility to show immersion-cooled Cell-to-Chassis battery

- CATL unveils Bedrock skateboard chassis with focus on safety

- Cell to body Technology in the new BYD Seal

Under the CTC battery technology, the electric cell can be integrated directly into the chassis, achieving a higher degree of integration.

Abstract The recently emerged cell-to-chassis (CTC) technology tremendously raises the energy density of the battery pack by directly integrating lithium-ion batteries into the The Cell to Pack (CTP), Cell to Body (CTB) and Cell to Chassis (CTC) Integrated Battery Market Report 2024-2035 covers the latest technologies, key applications,

Cell-to-chassis technology integrates the battery cell with the vehicle chassis, electric drive and thermal management. All battery components are housed in the vehicle body Cell to Pack (CTP), Cell to Body (CTB) and Cell to Market Report 2024-2035 covers the latest technologies, key applications, manufacturing processes, advantages, challenges, and

As Leapmotor states on its homepage, the corporate’s cell-to-chassis expertise (CTC) integrates the battery modules into the automobile physique. The person cells are thus Klassische Batteriegehäuse könnten bald der Vergangenheit angehören. Neue Pack-Architekturen wie Cell-to-Everything-Ansätze sollen die Zukunft sein. Erste Schritte dahin Its design prioritizes the battery, incorporating CTC (Cell to Chassis) technology, where the battery cells are directly integrated into the chassis. This integration enhances

This can be done by directly integrating cells into a pack without the use of modules, the so-called Cell-to-Pack concept which is used in structural battery systems. Auto companies are designing ways to build a car’s fuel cells into its frame, making electric rides cheaper, roomier, and able to hit ranges of 620 miles.

Cell-to-pack (CTP) designs integrate battery cells directly into the battery pack, eliminating intermediate modules to enhance energy density and

- Cervezas Artesana Russian Imperial Stout En Okasional Beer

- Certificat Interuniversitaire En Management Associatif

- Centdian Computation In Cactus Graphs

- Cele Mai Bune Filme Pe Care Nu Le-Ai Vazut

- Central Heating Systems Selection Guide: Types, Features

- Celestial Manipulation – Personal Astronomical Object

- Cerbios New Xbox Bios , [XB] Cerbios Tool v1.1.1 and Cerbios v2.3.0 Beta available

- Certified Organic Farm – Find Organic Near You: Interactive Map

- Ceramicspeed: Ausrüstung Und Zubehör Kaufen Bei Probikeshop

- Celtic Fusion Bands – Serena Smith & Friends: Celtic Fusion Band

- Central Do Brasil De Walter Salles