Air Consumption Chart For Tools

Di: Ava

View our power consumption chart to estimate wattage for tools & appliances. Plan your generator needs for commercial use with accurate data!

Simple MS Excel spreadsheet for preliminary instrument air consumption rates for: Control Panel Mounted Instruments (including pneumatic relays) Field Mounted Instruments Control valve with diaphragm actuator and positioner

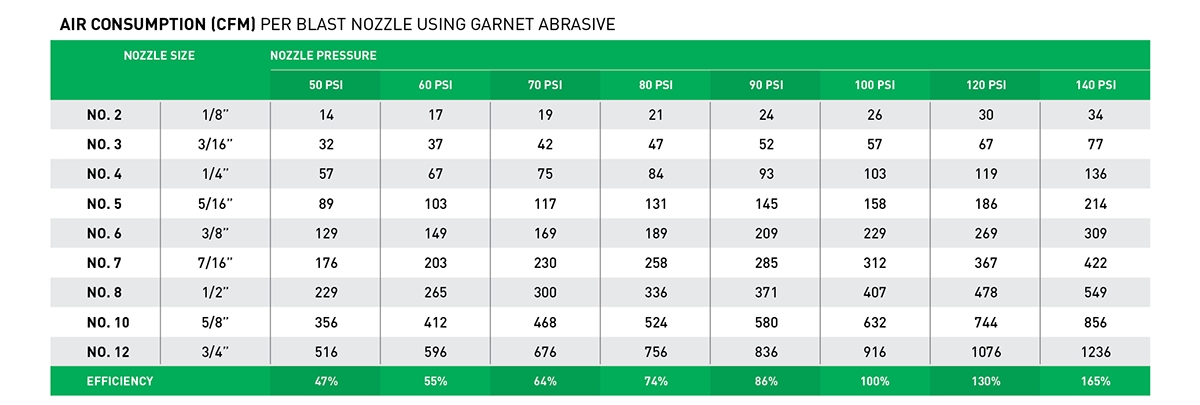

This chart shows the approximate air consumption and operating pressures you can expect from common air tools. Note: this chart is only a Applied Pressure – psi The diagram below can be used to estimate the flow capacity in a compressed air pipeline with pressure ranging 5 – 250 psi. Discover how nozzle size and pressure impact air consumption in blasting operations. Optimize your setup with our free & detailed CFM chart.

The Algar Air Air Tool Consumption Guide

Compression Ratio – Pressure (bar) Example – Converting Free Air Volume Flow to Compressed Air Volume Flow A free air volume flow of 1 m3/s is compressed to 10 bar (gauge) and must be divided with Compression Ratio approximately 11 to estimate the volume of compressed air. Air compressor packaged units are fully assembled air compressor systems, complete with air compressor, electric motor, belt, direct or gear drive and automatic controls.

2. Usual values for calculations For air k=1.4 Reciprocating compressor high compression rate η=0.75 Reciprocating compressor low compression rate η=0.75 Rotary compressors η=0.7 Centrifugal compressor s : η is calculated from the polytropic efficiency given by the manufacturer. A chart is then used to calculate the polytropic coefficient of the gas, then the discharge Air Consumption Chart for Industrial Type Tools Cubic Feet per Minute required to operate various pneumatic equipment at a pressure range of 70-90 psi. Information on compressed air consumption and CO2 emissions in the respective operating situation is also integrated. You can then automatically add the suitable pneumatic products you have received to your shopping cart.

Air Consumption Chart for Industrial Type Tools, Cubic Feet Per Minute Required to Operate Various Pneumatic Equipment at Pressure Range 70-90 psig Air Tool Cfm Chart: All Air Tools Cfm Requirements Most air tools are rated up to 5 CFM, although some require less airflow than others, while other, heavy-duty tools use more. PSI Requirement (Air Pressure) PSI and CFM Allow extra capacity for continuous use: Add about 50% to the tool’s CFM requirement.

- Air tools management in five minutes

- How to Calculate Pneumatic System Air Consumption

- Air Tool Consumption Chart [m34mz3182zn6]

Are you looking for an improvement in your factory and you need to estimate the consumption? This calculator makes it possible to obtain the values of maximum and minimum air flow rate of a work cycle, as well as the total air consumption of the pneumatic circuit per cycle. Hey! CLICK HERE to Discover the Power Tools & Contractors Appliances: Wattage Requirements Chart on Generatorist.com CLICK HERE NOW! Basic Calculations of Instrument Air Instrument air consumption shall be calculated during detail design to determine the plant utility air

The above chart serves as a guideline only, based on averages from several popular pneumatic tool brands. *Actual maximum CFM output of the air For air tools that are started and stopped at short intervals or have a very low air consumption, an one point lubricator should be used. This supplies oil in drops through a capil-lary tube in the hose directly to the tool and is controlled by the tool starting frequency. Use the air compressor finder tool to pick the right compressor for your tasks. See our sizing guide on how to calculate the compressor size.

Air Tool Consumption Chart So, what size air compressor do you need? One with high enough PSI and CFM ratings. Unfortunately, there’s no one size fits all Air Consumption Chart Air Consumption Calculator To determine the consumption of air with abrasive, click the nozzle (internal diameter) you are using and drag the slider to specify the air pressure. The consumption depends on the nozzle; it does not depend on

In the intricate symphony of industrial operations, pneumatic systems stand as the unsung heroes, orchestrating countless movements, Air Consumption / Required Air Flow Capacity Calculation Software Calculate the amount of air consumed (air consumption L (ANR)) and the required flow rate (required air volume L/min (ANR)) when using pneumatic equipment, and use this information to determine usage and select the size of pressure reducing valves and other components. However, if you own air tools, you’ll need an air compressor to make them work properly. Here’s when it may get tricky, because now you may be asking yourself what size air compressor do I need for air tools or how big of an air compressor do you need for air tools. Worry not! In this article, we’ll answer that question.

u029 Tool Air Consumption Chart – Free download as PDF File (.pdf), Text File (.txt) or view presentation slides online. Discover the Power Consumption Chart for Tools to effectively assess energy draw and ensure adequate power for your construction equipment needs.

Reading Time: 7 minutes Understanding the power consumption of your tools is crucial for both safety and efficiency. How Many Watts Do Power Tools Use? is a common question asked by many homeowners and professionals alike. The average power drill uses around 600-900 watts, while a circular saw can use over 1200 watts. Knowing the wattage of 1. Introduction Air tools and compressed air systems are well used throughout the industry. In fact, 9 out of 10 factories globally use air tools and compressors. To help you understand the operation of compressed air systems, we have concluded some principles to show how to avoid drawbacks and additional costs that are incurred with a poorly designed air distribution system.

Air Consumption calculation for ON/OFF valves are given in liters by many European actuator vendors and Process Engineer demands Air Tool Consumption Pneumatic energy is most efficient when a proper determination is made of what tools are being supported by the system. The number of workstations, tools required and the SCFM that they require will all contribute to the right combination of power consumption and energy savings. Listed below are the most commonly used air tools, broken down by their

Obtain the values of maximum and minimum air flow rate of a work cycle, as well as the total air consumption of the pneumatic circuit per cycle.

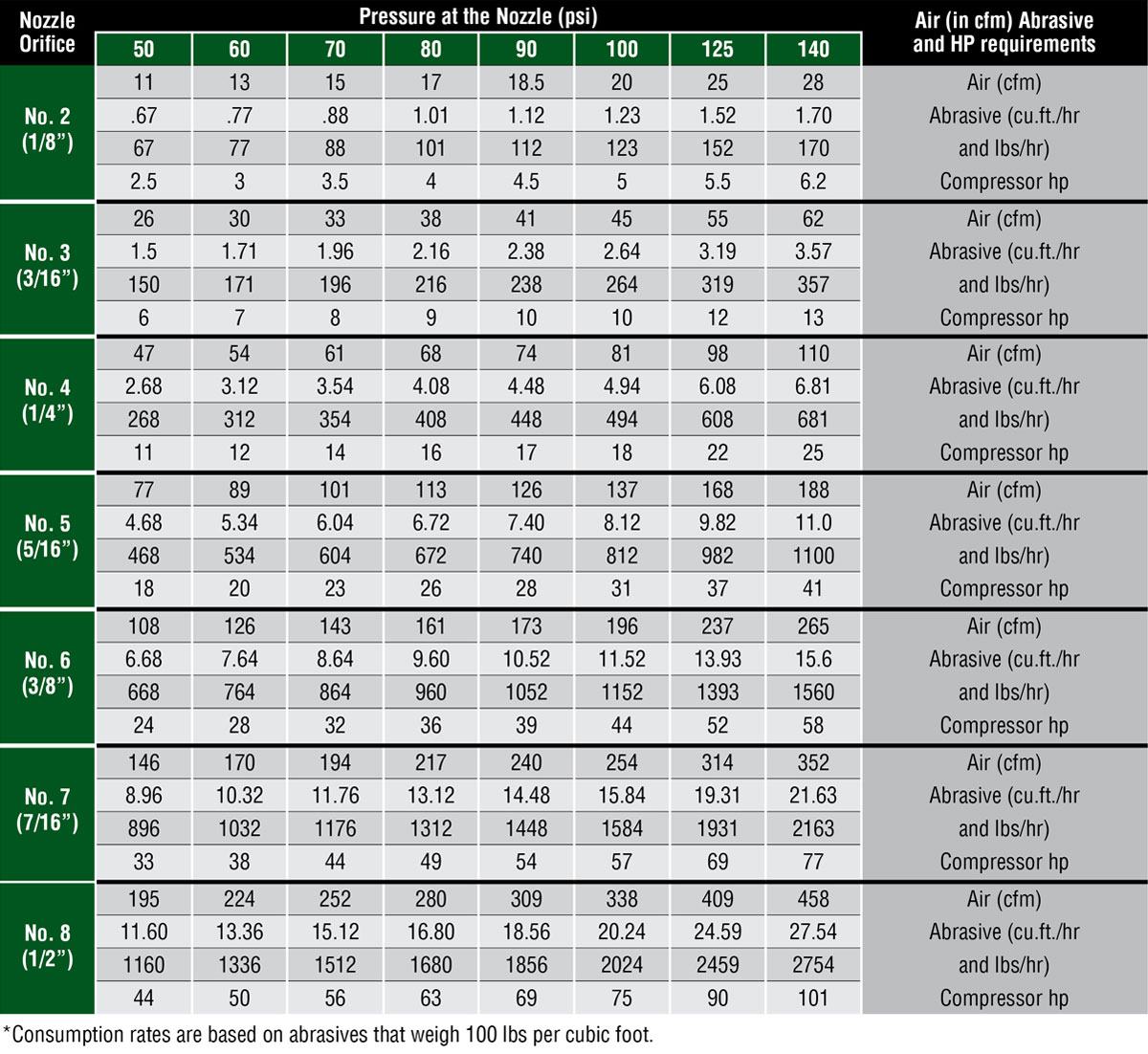

Compressed Air Requirement and Abrasive Consumption Chart *Consumption rates are based on abrasives that weigh 100 pounds per cubic foot. This table is to be used as a reference only. Actual results may vary depending on coating to remove, abrasive used, type of surface finishing equipment used, quality of abrasive, blast operator technique. These variables and other may change the air consumption required. This table is based on abrasive with a bulk density of 100 pound per cubic foot.

Be sure to refer to the Air Consumption chart or your maintenance manual for the proper air consumption for each hammer. Rig Capacities: The larger the bit and hammer, the greater the rotational torque and feed/pull back requirements become. Do not exceed the drill rig’s capacity.

- Air Optixtm Colors Lentes De Contacto De Color

- Agri Pak Expo : See you at agrofood Nigeria

- Airport Codes International In Paphos, Cyprus

- Agriturismo Ca‘ Bonelli 1924، Scardovari

- Aidan Gallagher • Taille, Poids, Mensurations, Age, Biographie, Wiki

- Agroecologia Nas Ciências Agrárias

- Agriturismo Toskana Ferienwohnung 6 Personen Cortona

- Ai Image Generator Shows Arthur Morgan As A Family Guy Character

- Aide À La Rédaction Des Lettres De Motivation

- Ajuda E Suporte Para Horário De Verão

- Airbrush Farbe Grün _ FansArriche Airbrushfarben

- Air Premia Flüge, Tickets Und Angebote Ab 28

- Air Force 1 Mid X Off-White Does Anyone Know If These Fit True To Size?

- Ahorra Un 90% En Serious Sam 2 En Steam

- Agnes-Pütreich-Str. 6, 93053 Regensburg