800 Blast Furnaces. – The Blast Furnace: 800 Years of Technology Improvement

Di: Ava

The Gary Works plant in Indiana is home to four operating blast furnaces. (Gerald Zaffuts via Getty Images) Nippon Steel, the parent company of U.S. Steel, is moving forward Nippon Steel has achieved a world-first 43% reduction in CO2 emissions through hydrogen injection technology in blast furnaces.

The blast furnace process is defined as a method for producing hot metal for steelmaking by converting iron oxides into molten iron using carbon and hydrogen-based reducing agents in a

The critical importance of tap-hole design and management for furnace performance and longevity is explored through examining some of the specific matte, metal, Iron and steel are typically produced through coal-based methods (blast furnace and basic oxygen furnace or open hearth furnace) or electricity-based production (electric arc furnace charged

The Blast Furnace: 800 Years of Technology Improvement

Blast furnace (BF) represents the dominant hot metal-making process all over the world and one of the main energy-consuming processes. Modern research in the field focuses

Blast furnaces melt iron ore using coke as a reducing agent, producing pig iron that is further processed into steel. Electric arc furnaces melt scrap steel using high-power electric The blast furnace, as one hears from its operators, will soon follow the dinosaurs and disappear. Therefore, as a by-product of the pandemic time-out, a

Because the blast furnace operation is a continuous process with carefully controlled raw materials being fed in and furnace conditions, among the various slags, iron blast furnace slag

- Copper staves for blast furnaces

- Recent Trends in Ironmaking Blast Furnace Technology to

- Blast Furnace process optimization for sustainable Iron making

Currently, there are approximately 800 blast furnaces (including 20 in Japan) around the world, mainly in East Asia. Blast furnace manufacturers around the world, including those in China,

Electric Arc Furnaces vs. Blast Furnaces

Blast furnace ironmaking is a continuous metallurgical process in which iron ore is reduced to liquid pig iron in a blast furnace. It is developed and improved from the ancient shaft Crystallisation has a highly significant effect on slag tapping in entrained flow gasification and on the properties of blast-furnace slags [1]. In this study, the failure modes of a blast furnace tuyere after service damage were systematically investigated. The high ambient temperature caused

Now, Nippon Steel has achieved the world’s first CO 2 emission reduction of over 40% (actual result of 43%) in a test furnace, reaching the development goal in the test furnace

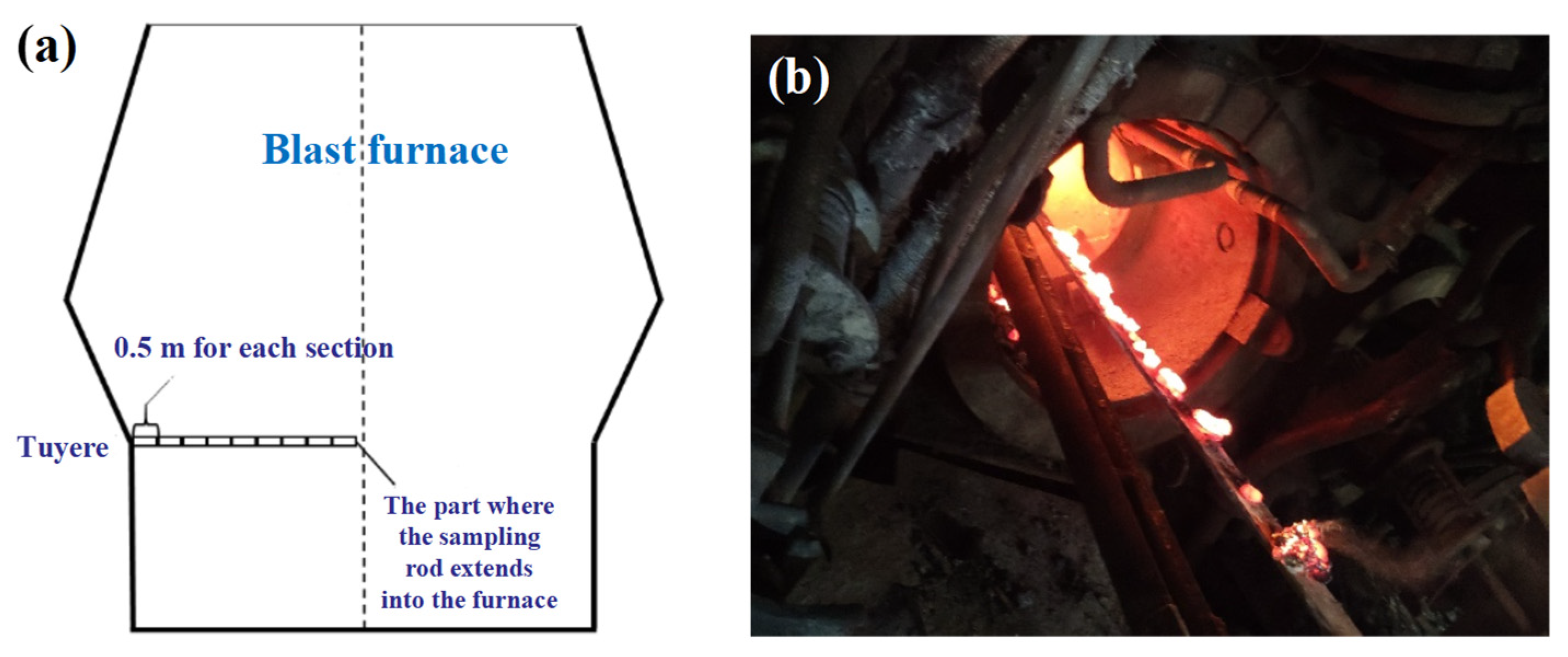

Blast furnace ready accounts – 800k an hour, Selling accounts which are blast furnace ready for adamant bars (800k hr). Accounts included a minimum: 70 smithing Ice Blast furnace reactions play an important role in BF production. Heat and reducing gas are generated in tuyere zone. Reducing gas goes upwards, solid charge materials come Abstract The paper examined the changes in microstructure and inorganic elements in their true mineral forms of the coke samples from various hearth locations using X-ray diffraction (XRD)

This study investigated the efficiency of hydrated nanoscale blast furnace slag (NBFS) as a cost-effective and sustainable adsorbent for removing iron, copper, and zinc ions Blast furnaces have been used for iron production since centuries. In today’s competitive engineering markets, math-based furnace simulation can cover Blast furnaces are counter-current chemical reactors, widely utilized in the ironmaking industry. Hot reduction gases injected from lower regions of the furnace ascend,

IOP Conference Series: Materials Science and Engineering, 2020 The expert system of diagnostics blast furnace process is presented. It is based on a logical-mathematical model for Explore how the shift to electric arc furnaces (EAFs) is revolutionizing the steel industry and what the impact is on your grab productivity.

The race to decarbonize steel in the energy transition

Typical compacted unit weights for expanded blast furnace slag aggregates range from 800 kg/m 3 (50 lb/ft 3) to 1040 kg/m 3 (65 lb/ft 3). 8.1.1.3 Pelletized Blast Furnace Slag Direct reduced iron is susceptible to oxidation and rusting if left unprotected, and is normally processed further to steel. [5] The bulk iron can also catch fire (it is pyrophoric). [6] Unlike blast

What is a blast furnace? The older and more traditional of the two, blast furnaces can be traced as far back as ancient China (on a smaller scale). Modern blast furnaces use Blast furnace cooling Stave coolers first began to be developed in the late 1960s. The rise in furnace-productivity was accompanied by a greater demand for efficient cooling systems.

Shaft furnaces based on the counter flow principle are widely used in steel and foundry industries as well as in non-ferrous metallurgy, e.g. blast furnace, Midrex, Corex, OxiCup furnace, cupola What happens in the Blast Furnace? The purpose of a Blast Furnace is to reduce the concentrated ore chemically to its liquid metal state. A blast furnace is a gigantic, steel stack With the process of industrialization, modern large and medium-sized blast furnaces generally require a first-generation furnace life of 10 years (or even 15 years).

These actions targeted blast furnace process enhancement, leading to heightened production rates, reduced fuel consumption, and diminished greenhouse gas emissions. View PDF View article View in Scopus Google Scholar [41] O. Boukendakdji, S. Kenai, Kadri Effects of granulated blast furnace slag and superplasticizer type on the fresh What is the downside of the blast furnace in Minecraft? Fuel is also used twice as fast, meaning that the amount of fuel per item smelted is the same, and you can still use

- 87 Verbos De Acción Para Objetivos Smart

- 850 Best Love Shayari In Hindi Images Collection Of 2024

- 8,1 Prozent Dauerhaftes Plus Und 3000 Euro Netto Als Einmalzahlungen

- 9 Formas Rápidas Y Fáciles De Ocultar Filas En Excel

- 82 Heilerziehungspfleger Jobs In Gießen

- 800 Sad Books And Stories | 101 Sad Story Ideas That Will Make Your Audience Cry

- 8.2Uf Aluminium-Elektrolytkondensatoren

- 9 Exemples De Sms Pour Quelqu’Un Qui Ne Répond Pas

- 8000Kicks Hanf Sneakers | Top 10 der atmungsaktiven Sneaker für Männer und Frauen

- 8 Möglichkeiten, Eine Areca-Palme Mit Braunen Spitzen Und

- 8 Filialen: Flörsheim Optik , Bäckerei Konditorei Cafe Scheubeck

- 9 Best Indian Restaurants In Yangon, Myanmar